Next, 136 kg (300 lb) of the absorbent was add-

the test section would have been impassable in

ed (Fig. 20) and mixed with a grader (Fig. 21). The

4-wheel drive before treatment. A loaded 5-ton

grader trafficked only the test section and did not

dump truck was then driven through the test sec-

use its blade or scarifying teeth to mix the soil and

tion (Fig. 23 and 24). It left approximately 102-

absorbent. After mixing, a dozer was used to

mm- (4-in.-) deep ruts in the center and 203-mm-

back-blade the test section and provide a smooth

(8-in.-) deep ruts on either end. The 5-ton dump

surface. The center of the section was dryer than

truck then trafficked the section 30 times and left

the ends. This was due to standing water before

178- to 279-mm- (7- to 11-in.-) deep ruts in the

the absorbent was added at the far end of the test

center and far end and 356-mm- (14-in.-) deep

section and not enough absorbent being added to

ruts at the near end (Fig. 25). The rutting was not

caused by the soil being too "wet" but the result

the near end of the test section.

of a lack of cohesion. At the end of the test the soil

A Commercial Utility and Cargo Vehicle

looked dry and friable. The average water con-

(CUCV) was driven across the test section leaving

tent of the top 76 mm (3 in.) of soil was 17.8%. Its

approximately 51-mm- (2-in.-) deep ruts in the

grain size distribution was not determined. The

center of the section and 152-mm (6-in.) ruts on

cone penetrometer test results were not valid

either end (Fig. 22). The CUCV was able to drive

through the test section in 2-wheel drive when

because the cone hit the larger gravel pieces.

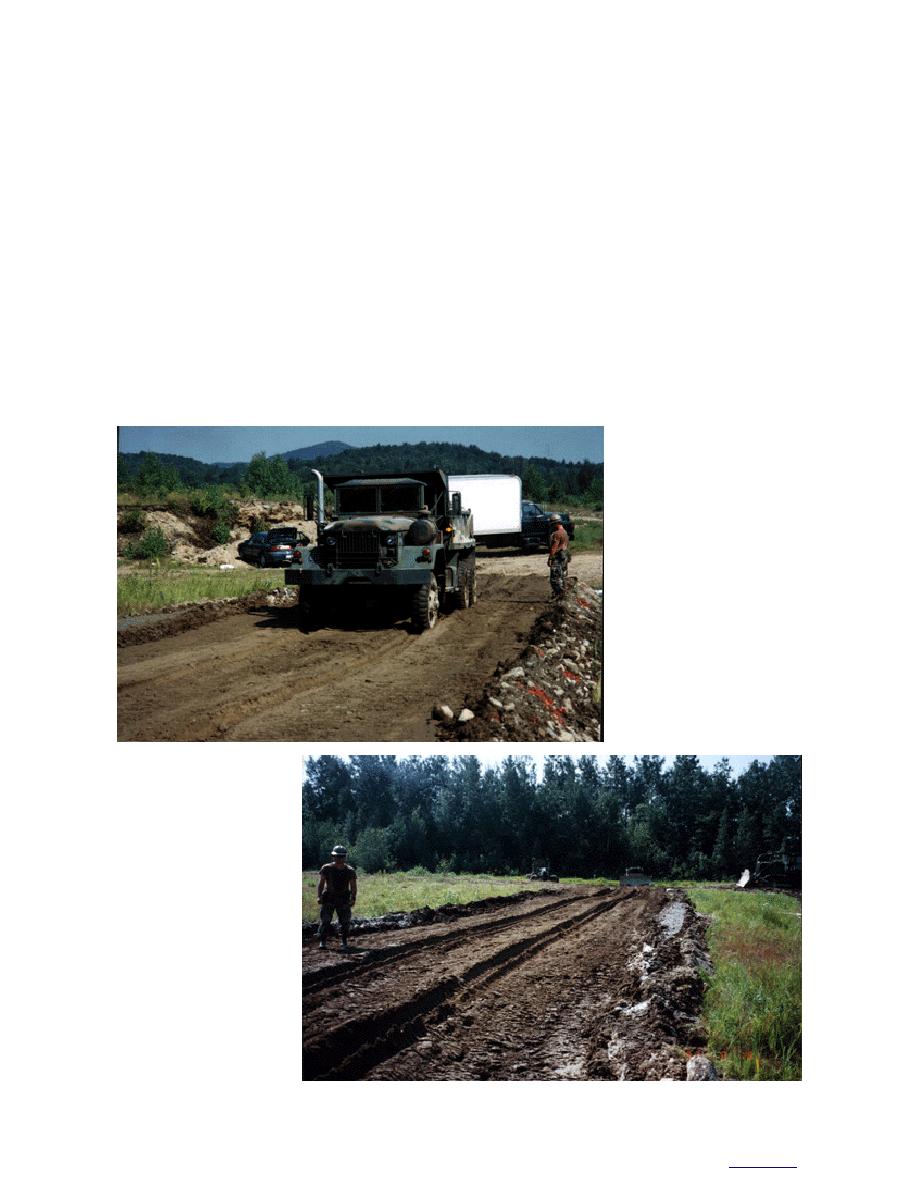

Figure 23. Trafficking the sec-

tion with a 5-ton dump truck.

Figure 24. Test section after

one pass with a 5-ton dump

truck.

15

Previous Page

Previous Page