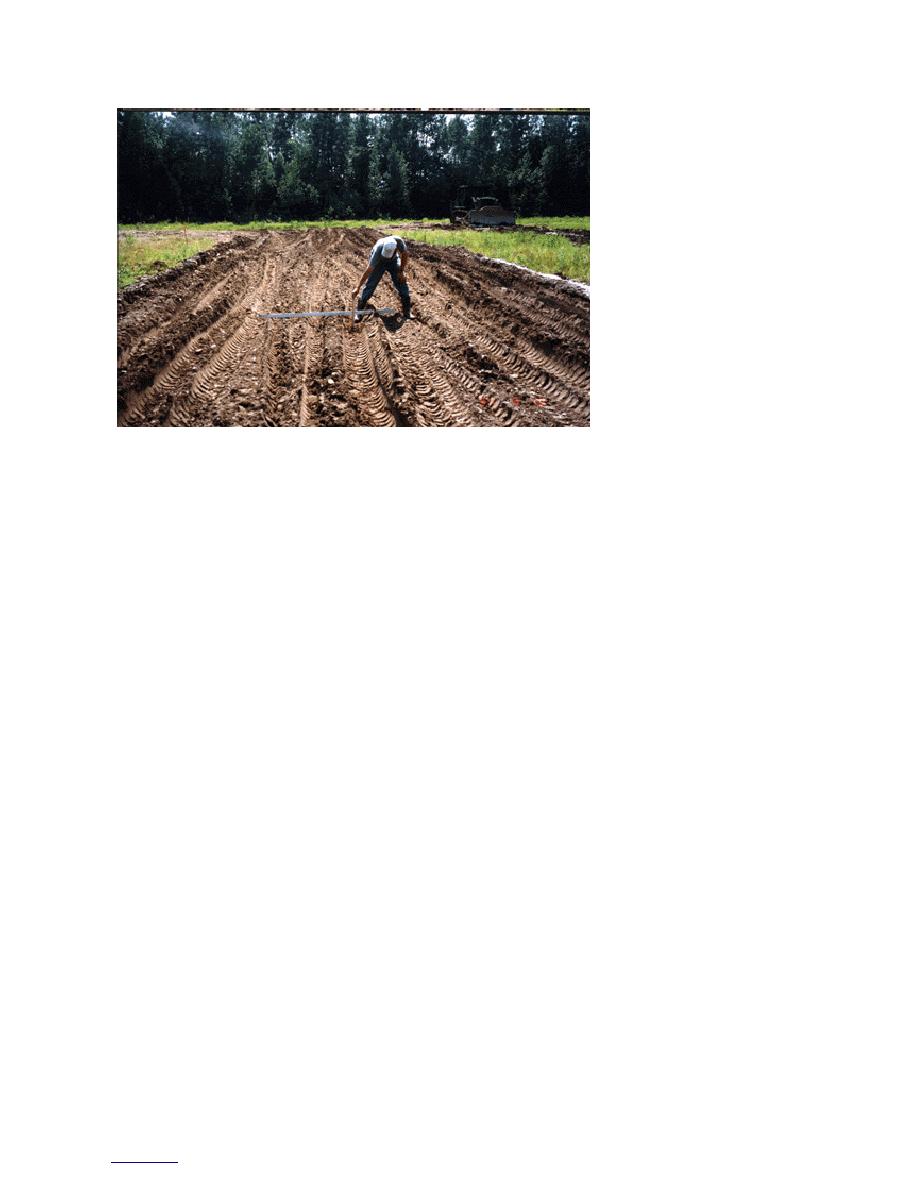

Figure 25. Test section after 30

passes with a 5-ton dump truck.

OBSERVATIONS

made excavating the soil and providing smooth

Following are observations that were made

surfaces difficult. Not providing a smooth bottom

surface will increase the likelihood of the mem-

during the project. Many minor problems com-

brane being punctured.

pounded one another. Some of these could be

Membranes. The membranes performed well

solved by using different equipment or more

overall with a few minor difficulties. They quickly

skilled operators. Other problems, including the

became covered with a fine film of dust that had to

weather, the type of native soil available, and

be removed before the tape was applied. Water or

membrane folds, are difficult or impossible to

rubbing alcohol effectively removed the dust. It

control in the field.

was important to replace the wiping towel as soon

as it became dirty.

MESL demonstration observations

The membranes come folded from the manufac-

These observations are from the construction

turer. As the thickness increases, the folds take

of the MESL and the puncture test. Both had

longer to flatten. This would also be affected by

numerous problems that primarily involved

temperature, with colder temperatures increasing

equipment availability and operation.

the time. The membranes also were factory-

seamed to form larger sheets. Sealing across the

MESL test

seams could be difficult and a source of potential

The MESL test was much more time-consum-

leaks.

ing than planned. It was originally scheduled to

Placing membranes. The membranes were easy

be finished in three to four days and took nine

to place when there was no wind, but because

days. Most of the delays were due to the lack of

they are very large, a strong wind can make it diffi-

equipment and operators.

cult or impossible to place them (Fig. 26). The

Weather. The weather is critical to the success

membranes also needed to be held down if the

of the project. Construction cannot take place

wind increased after they were placed.

during rainy periods. Rain could also turn the

Several troops were required to place the mem-

excavated, unfinished MESL into a large pool.

branes. As the size increased, the number of troops

Wind is also a factor. It can make placing the

required also increased. Four to six troops worked

membranes difficult. If the area is very dry, the

well for the membranes (10.7 36.6 m [35 ft 120

construction process can generate a large amount

ft]) used in this project.

of dust, making the membranes dusty.

Tape. The tapes worked very well. Fab tape was

Excavation of native soil. Excavating the

preferred because it was easier to use. It is more

native soil can be done with a variety of equip-

robust, has more tension strength, is not blown

ment. During the demonstration project the

around by the wind as easily, and can be adjusted

troops were limited to pans and a D-7 dozer. This

16

Previous Page

Previous Page