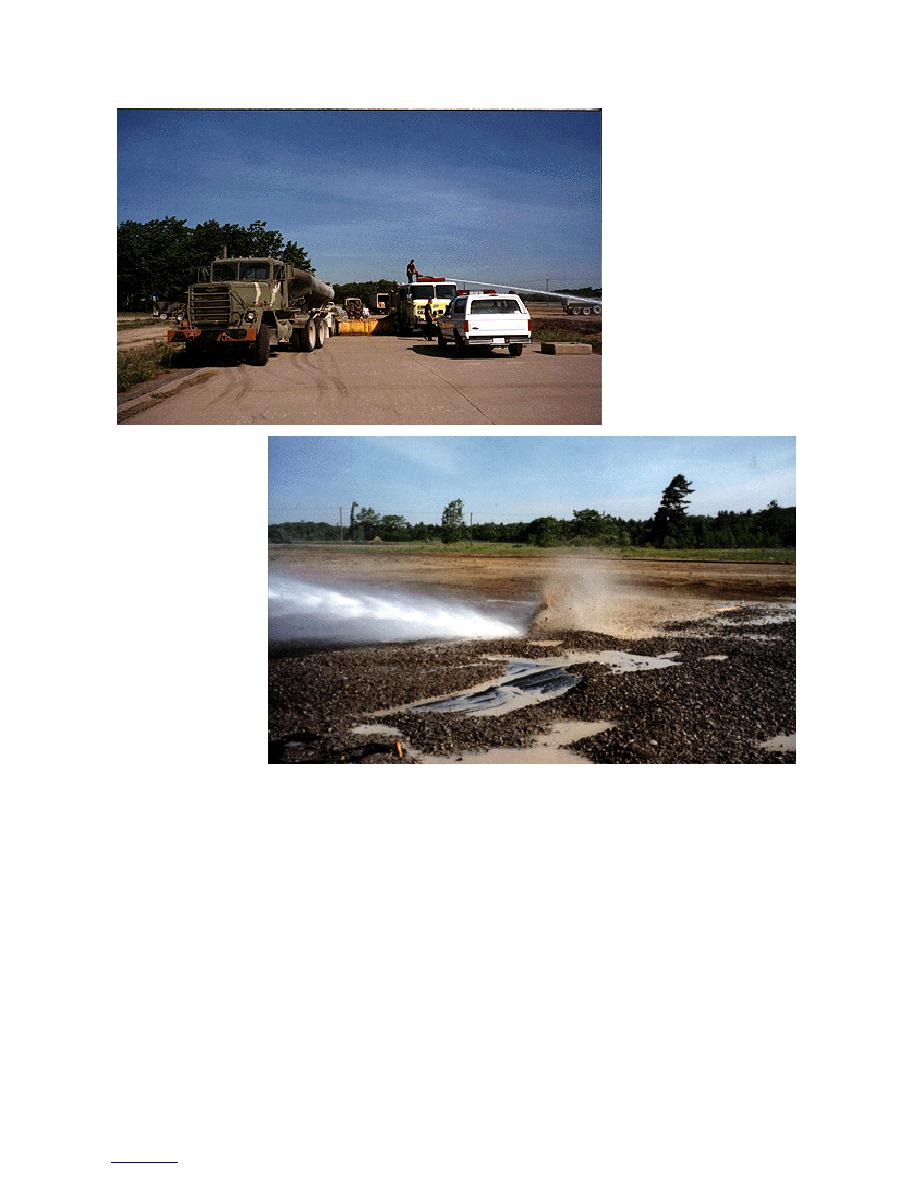

Figure 15. Equipment used to

wash gravel off the test section.

Figure 16. Washing

gravel.

mized damage to the membrane. The membranes

10 August 1997. The 131st Engineering Unit of the

Vermont National Guard did the construction.

were then visually inspected for damage and

The test site was an old gravel pit. Because of

punctures.

the low quality of the gravel (due to a high fines

content), it was typically used as a fill material at

Absorbent demonstration

least 0.61 m (2 ft) below the road surface. A thin

The original plans included constructing an ad-

ditional MESL with a dirty sand/gravel as the fill

organic layer had formed on the gravel and sup-

soil at the Ethan Allen Firing Range (EAFR) in Jer-

ported grass growth. A test section approximately

icho, Vermont. The plans were changed when it

4.57 m (15 ft) wide by 130 m (100 ft) long was pre-

was determined that MESLs could not be con-

pared for the test. The existing material was mixed

structed by the 365th Combat Heavy Engineering

together using a dozer, and additional silty sand

Battalion during the Fort Drum demonstration be-

was added. Water was added to make the soil

cause of the limited amount of time the engineers

muddy (Fig. 17). The wet layer was approximately

were available at EAFR. The new plan was to test

305 mm (1 ft) deep with a solid layer underneath.

the absorbent in a wet soil and qualitatively evalu-

When trafficked, a 5-ton truck (Fig. 18) would sink

ate its performance.

to the hard layer, and in some places the soil was

The absorbent test was conducted at EAFR on

too weak to maintain the wheel ruts (Fig. 19).

12

Previous Page

Previous Page