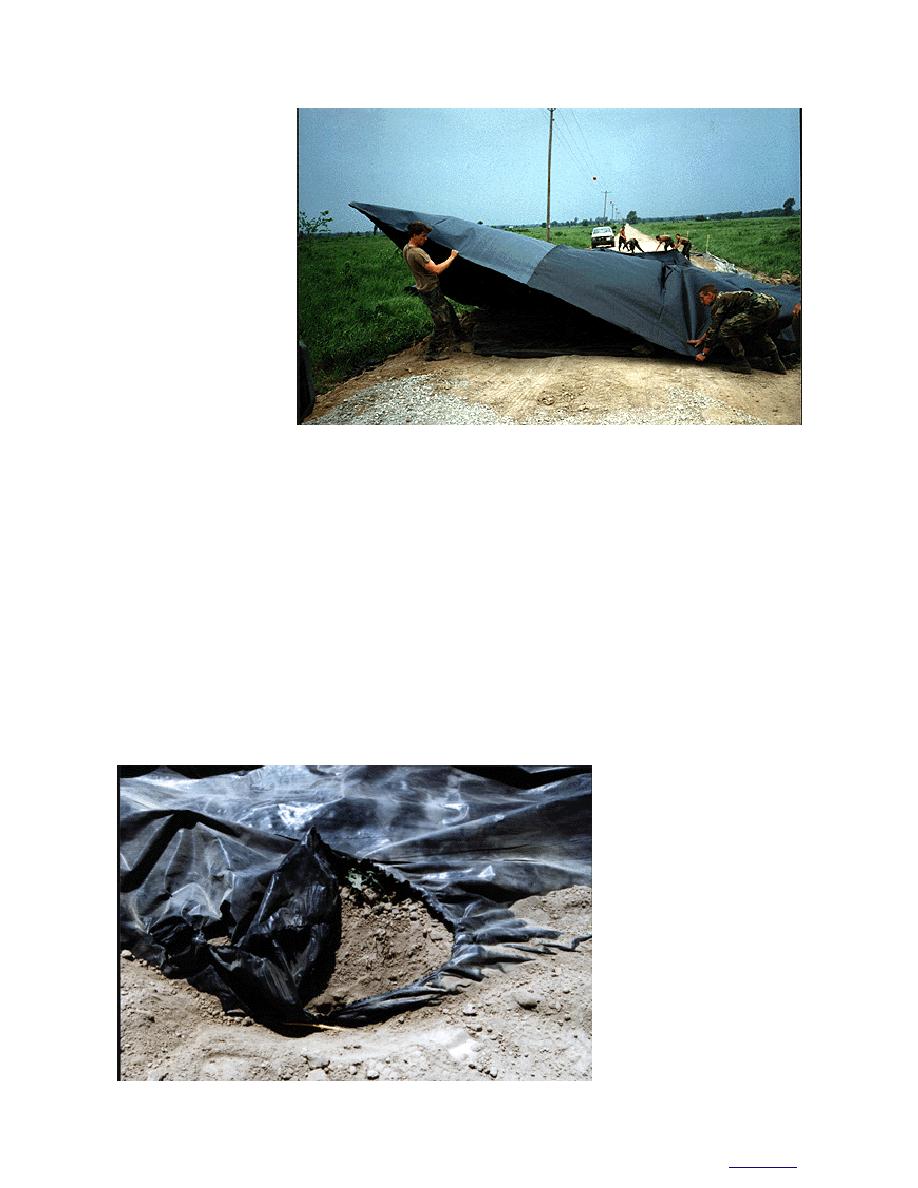

Figure 26. Placing top

membrane during light

winds.

Cutting the final grade or removing any excess

after it is placed on the membrane. The Poly Seal

soil from the edge near the membrane requires

tape is permanently adhered to the plastic as soon

great care. It may be necessary to use brooms or

as it touches it.

shovels to remove excess soil.

It is recommended that both tapes be kept

above 10C (50F) before use, e.g., by keeping the

It is critical that the top surface be smooth with

no loose material. Because the upper membrane

tape in a heated vehicle. It is also possible to heat

is not protected from the fill material and small

the tape and the membrane with a heat gun as the

stones, hard soil particles, etc., can easily punc-

tape is being applied. (As mentioned in the

ture the membrane. Small stones may be tracked

"Membrane sealing" section, using a heat gun

on the surface by vehicle tires, shoes, etc.

would require a generator.)

Sealing membranes. The membranes must be

Placing, compacting, and grading the encap-

clean for the tape to bond properly. Dust quickly

sulated soil. This is one of the most difficult steps.

accumulates on the membranes. If the soil becomes

The initial lift must be placed carefully to avoid

wet at any time the membranes may become

damaging the lower membrane. Care must also

muddied and then must be cleaned. The mem-

be taken when spreading and compacting near

branes can be cleaned with water and, if required,

the sides of the membranes. The membrane can

rubbing alcohol.

be torn easily by the heavy equipment (Fig. 27).

Figure 27. Membrane tear.

17

Previous Page

Previous Page