The most difficult part of sealing the mem-

Lime mixing. Mixing the lime and the clay soil

branes is caused by the folds or creases in the

went well. The lime was mixed into the top 102

membranes. The bottom membrane had numer-

mm (4 in.) of soil. Mixing to greater depths would

ous folds caused by the irregular excavation. The

have been difficult. Maintaining a uniform mois-

top membrane had a few larger folds caused by

ture content is important. Removing the mixed soil

the irregular soil surface.

for trucking to the MESL site was challenging. At

It may be necessary to walk on the membranes

times too much soil was removed and untreated

when sealing them. Care needs to be taken not to

clay was added to the clay-lime mixture.

puncture the membranes when doing so. Stones

caught in shoe treads can easily puncture the

Puncture test

membrane. Hard-soled shoes also can cause

It is critical that the upper membrane not be

problems.

punctured during construction or trafficking.

MESL ends. The MESL ends are the most com-

Even one puncture can lead to localized failure of

plicated part of the construction. The bottom

the MESL. If the failure is not corrected immediate-

membrane needs to be protected as the MESL is

ly, its size can increase rapidly. Traffic and wet

filled. Vehicles carrying fill soil need to travel

weather will speed the rate of failure. Therefore,

over the bottom membrane at the MESL ends.

one puncture was considered failure. The number

Geotextiles and plywood are possible methods of

of punctures was not quantified. Visual observa-

protection, but must be removed when the fill soil

tions were taken mostly along the wheel paths.

is in place so the membranes can be sealed.

The results are divided by the amount of protec-

When the membranes are sealed, the side of

tion used. The Permalon Ply X-210G (composite

the bottom membrane needs to be sealed to the

membrane) was analyzed separately because it

end of the bottom membrane. The top membrane

has some protection without a separate geotextile.

is then sealed to the bottom membrane. The exact

No protection. Two membranes without protec-

sealing order and method will change from site to

tion had the following test results.

site and needs to be determined in the field.

RUFCO 2010B. The membrane had numerous

Placing the geotextile. Placing the geotextile

puncture holes ranging from 12 to 50 mm (0.5

was easy and went quickly. Troops should walk

to 2 in.), depressions, scratches, and stretch

on the geotextile and not the membrane. Care

marks.

Permalon Ply X-210. There were numerous

must be taken when walking on the geotextile

holes and many depression marks on the mem-

because it will slide on some membranes.

brane.

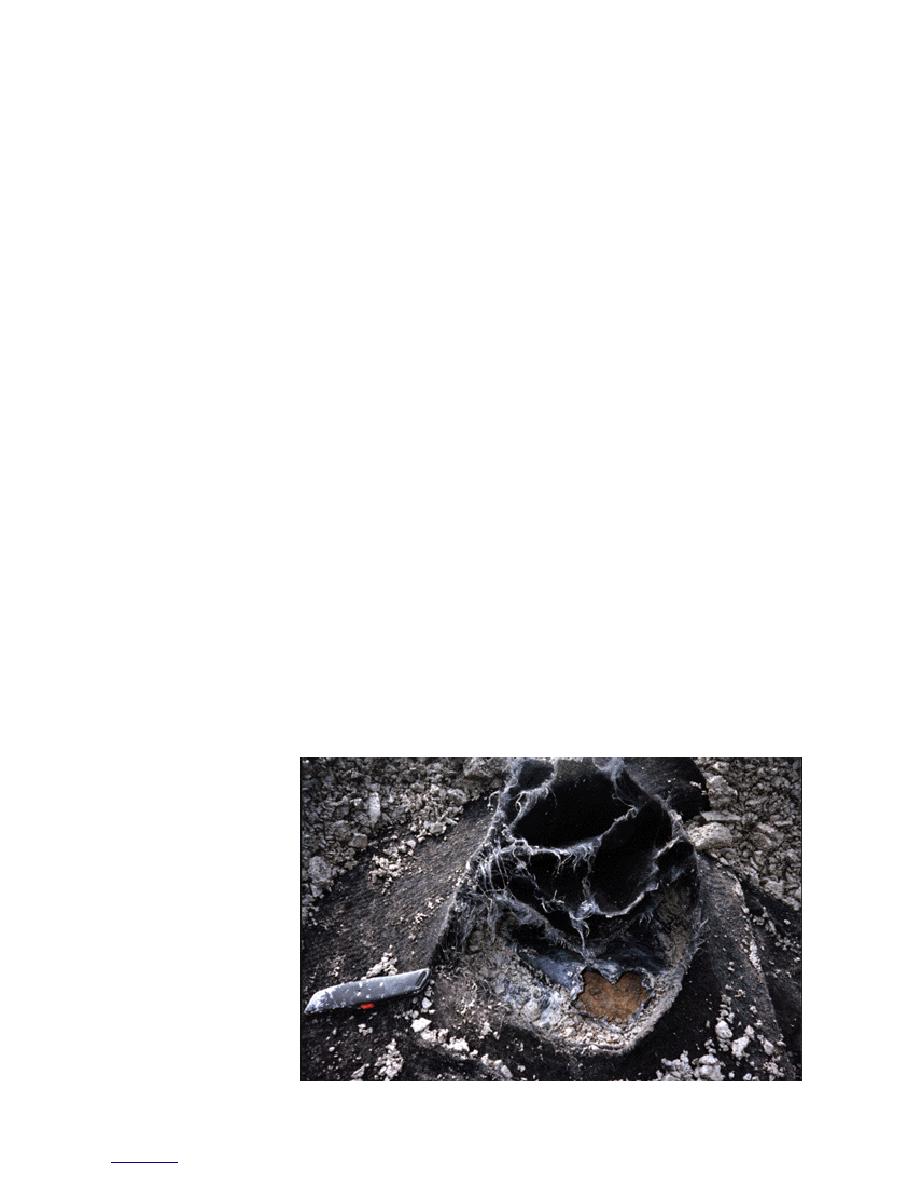

Placing the wearing course. A 152-mm (6-in.)

gravel wearing course was used. It was difficult

One-layer geotextile.

to place a uniform thickness of gravel because the

RUFCO 1010B. There were many continuous

scratches on the wheel path, long stretch

surface of the MESL was not level. Care is still

needed when spreading

the gravel. A bucket

loader caught the top of

the MESL when spread-

ing the gravel (Fig. 28).

Figure 28. Top-membrane

tear, caused by a bucket

loader.

18

Previous Page

Previous Page