MESL test

yard bucket loader were used to excavate the sec-

Two MESLs and a control section were con-

tions to a depth of 457 mm (18 in.). The material

structed. MESL 1 used lime-treated clay as the en-

was loosened by using the ripper teeth on the D-7.

capsulated soil, and MESL 2 used untreated clay

The loosened material was then removed using

as the encapsulated soil. MESL 1 used two differ-

the pans and transported for use at a different

ent membranes on top and bottom (Fig. 3). One

construction site.

The D-7 and the bucket loader were used to

reason for doing this was to determine whether

smooth the excavation. The area was then cleared

there were any difficulties seaming two mem-

of any sharp material by hand and the lower

branes together. To protect the upper membrane,

membranes were placed in the excavation. At the

one layer of geotextile was placed on one side of

locations where a seam was needed, the mem-

the road and two layers of geotextile were placed

branes were cleaned with isopropyl alcohol and

on the other side.

wiped dry. Tape was applied and the membranes

MESL 2 was constructed similarly to MESL 1

were joined. A small hand-held roller was used to

except the top and bottom membranes did not

smooth the seam and ensure a watertight seal.

have a seam in the middle. The amount of geotex-

The ends of the membrane were folded back to

tile protection was increased to two layers on

the edge of the excavation and covered with geo-

each side and an additional layer in the middle.

textile fabric and plywood to prevent damage

The control section was similar to MESL 2 except no

from the trucks dumping the fill material.

membranes were used. The MESLs were approx-

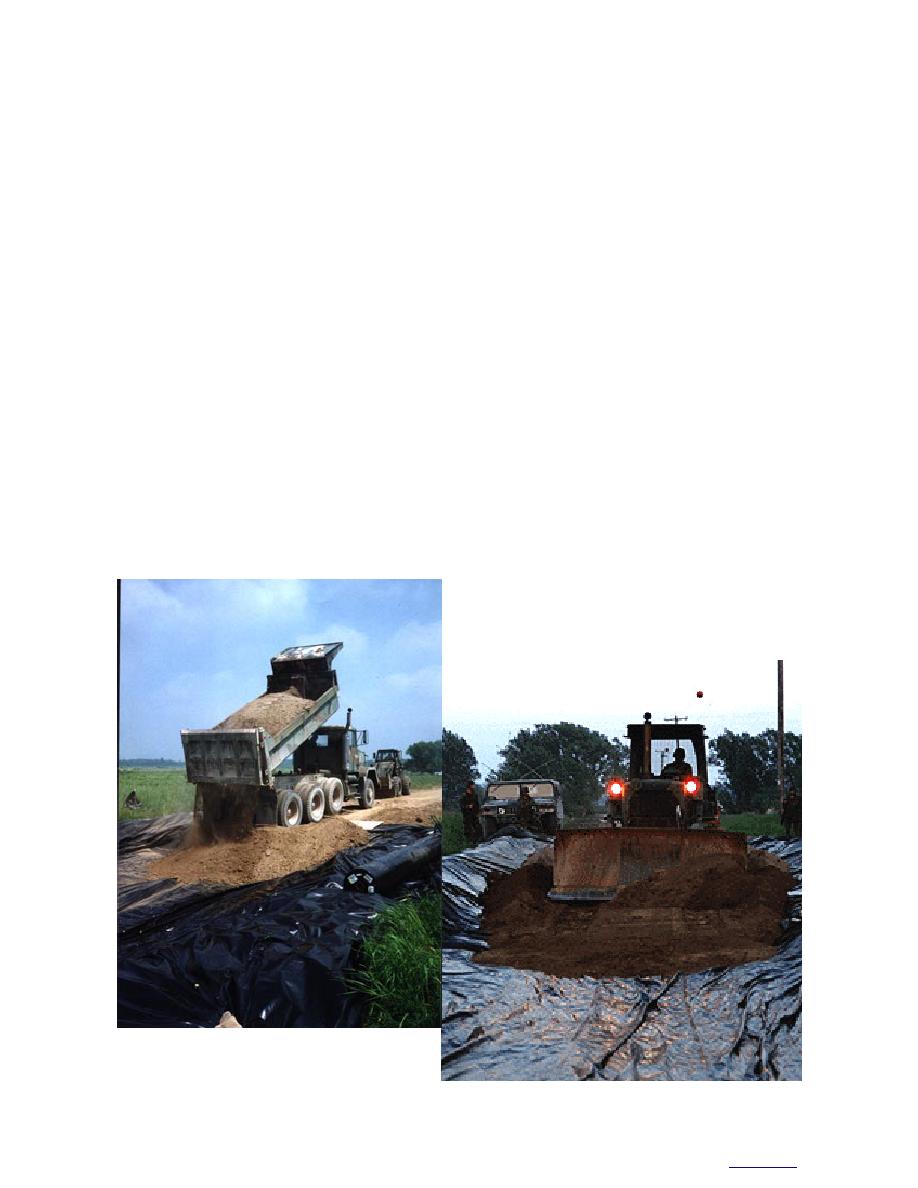

The fill material was transported to the site in

imately 457 mm (18 in.) deep and 6.7 m (22 ft)

20-ton dump trucks. Because vehicle traffic

wide.

would damage the membranes, the trucks had to

back to the edge of the excavation to dump the fill

MESL construction

soil (Fig. 4) and a dozer pushed the material over

The MESL construction was conducted at

the membrane (Fig. 5). A loaded 20-ton dump

Poagland Road. A D-7 bulldozer, pans, and a 2.5-

Figure 4. Placing fill soil inside the MESL.

Figure 5. Using a D-7 to spread soil in the MESL.

7

Previous Page

Previous Page