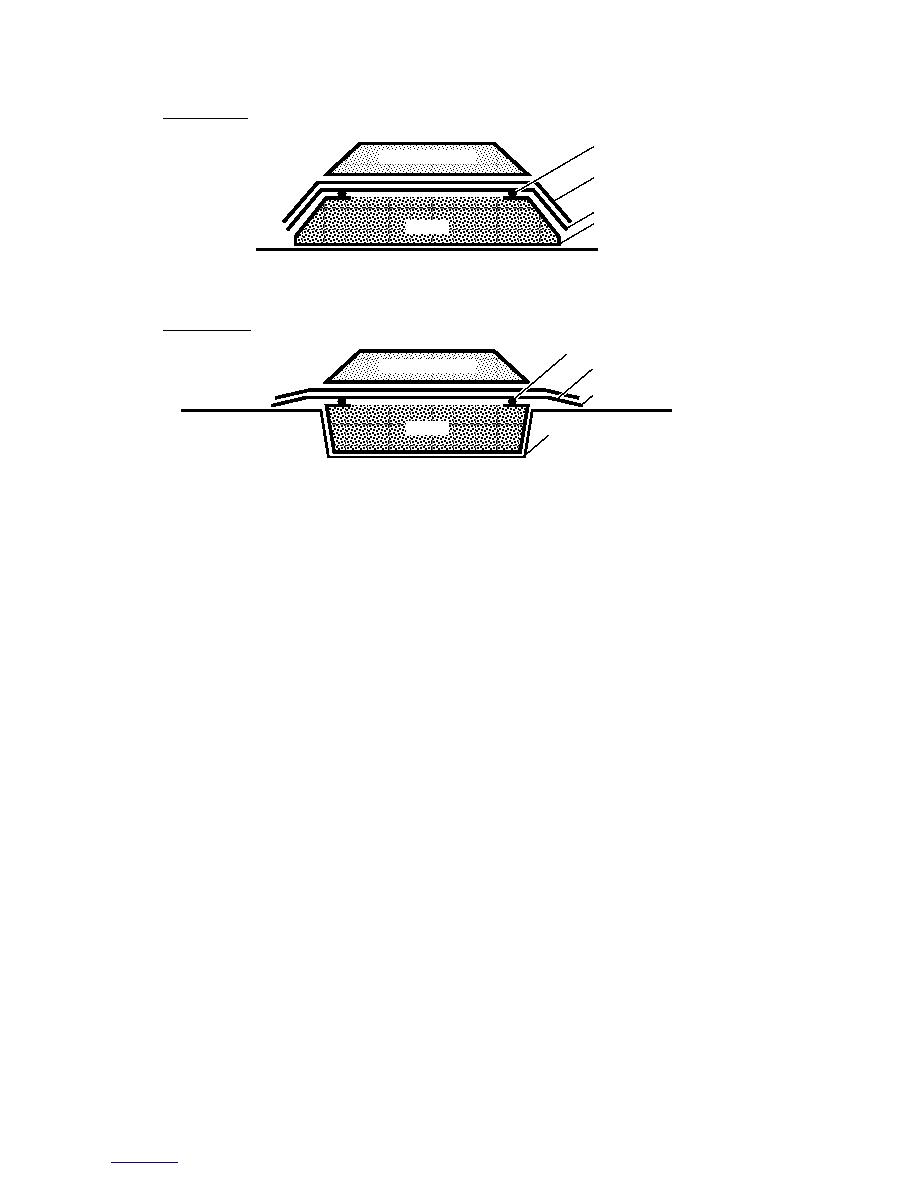

Most Expedient

Requires Borrow Soil

Membranes Exposed

Membrane Sealing

Wearing Surface

Membrane Protection

(Geotextile)

Upper Membrane (Plastic Film)

Lower Membrane (Plastic Film)

Fill Soil

Subgrade

a. On top of subgrade.

Least Expedient

Uses Native or Borrow Soil

Membrane Sealing

Membranes Protected

Membrane Protection

Wearing Surface

(Geotextile)

Upper Membrane (Plastic Film)

Subgrade

Fill Soil

Lower Membrane (Plastic Film)

b. In the subgrade.

Figure 1. Cross sections of typical MESLs.

asphalt using a chip spreader to prevent tires

Current materials

The following information is primarily from

from picking up the asphalt.

Implementation Package 74-2, Users Manual for

Membrane Encapsulated Pavement Sections (MEPS),

Membrane sealing materials

by S.L. Webster (1974b).

Emulsified asphalt is used to seal all the mem-

branes. At least a 0.3-m (1-ft) overlay should be

Lower membrane

used at all seams.

The lower membrane is formed by first spray-

Membrane protection and wearing surface

ing emulsified asphalt on the soil at a rate of 0.9 to

1.4 L/m2 (0.2 to 0.3 gal/yd2) on the subgrade.

Protection is not required if only wheeled vehi-

cles are going to use the newly constructed road.

This holds the plastic membrane in place and can

It will last for approximately 10,000 passes with

seal small punctures that occur in the plastic

very little maintenance (Webster and Andress

membrane, which is typically 0.152-mm- (6-mil)

1976, Webster 1996), but vehicles cannot make

thick polyethylene, 9.1 to 12.2 m (30 to 40 ft) wide

sharp turns or sudden starts and stops. If a gravel

and 30.5 m (100 ft) long. The membranes are

wearing surface is going to be used, 51 mm (2 in.)

joined together by overlapping the sheets by two

of "cushion" sand is used between the membrane

to three feet and spraying emulsified asphalt

and the gravel to prevent puncturing of the mem-

between them.

brane (Smith 1979). An asphaltic concrete pave-

ment wearing course will also provide the needed

Upper membrane

membrane protection (Webster and Andress

The surface of the finished soil layer is first

1976).

sprayed with a small amount of water to dampen

it, and is then sprayed with 1.1 to 2.3 L/m2 (0.25

to 0.5 gal/yd2) of emulsified asphalt. A needle-

Encapsulated soil

The encapsulated soil is typically one that loses

punched nonwoven polypropylene fabric (such

considerable strength when it gets wet, such as a

as Petromat) is unrolled on top of the emulsified

clay or silt. The soil needs to be placed at moisture

asphalt. The fabric is then sprayed with 0.9 to 1.4

L/m2 (0.2 to 0.3 gal/yd2) of emulsified asphalt. A

content near its optimum or lower in warm cli-

mates. In cold climates, where freezing of the soil

thin layer of blotter sand (dry sand passing the

will occur, the soil should be placed so it is no

number 4 sieve) is spread on top of the emulsified

2

Previous Page

Previous Page