Table 1. Core sample findings for roof D1.

Moisture

content

Thickness

(% of

TRR

Core

Insulation

(in.)

dry weight)

(%)

Status

1

EPS

0.87

0

100

dry

1

EPS

2

8

99

dry

1

FGL

2.5

25

88

dry

1

FGL(frozen)

1

455

16

WET

2

EPS

2

0

100

dry

2

FGL

2

0

100

dry

2

FGL

2

0

100

dry

2

FGL(frozen)

3

295

25

WET

8

EPS

2

2

100

dry

8

FGL

2

0

100

dry

8

FGL

2

1

99

dry

8

FGL

1

1

99

dry

8

FGL(frozen)

1

407

18

WET

13

EPS

2

1

100

dry

13

FGL

2

0

100

dry

13

FGL

2

0

100

dry

13

FGL

2

0

100

dry

Notes:

EPS = expanded polystyrene

FGL = fibrous glass

Samples are tabulated above as they are positioned in the roof from top to bottom.

Core 1: Taken near edge of roof where additional EPS was present as a tapered edge strip.

Additional frozen fibrous glass existed below the portion sampled. It was probably about

3.5 in. thick.

Core 13: All of this sample was recovered down to the concrete deck and no frozen material

was present. The thickness of fibrous glass does not add up to 7 in. This is probably due to

the compression it experiences upon sampling.

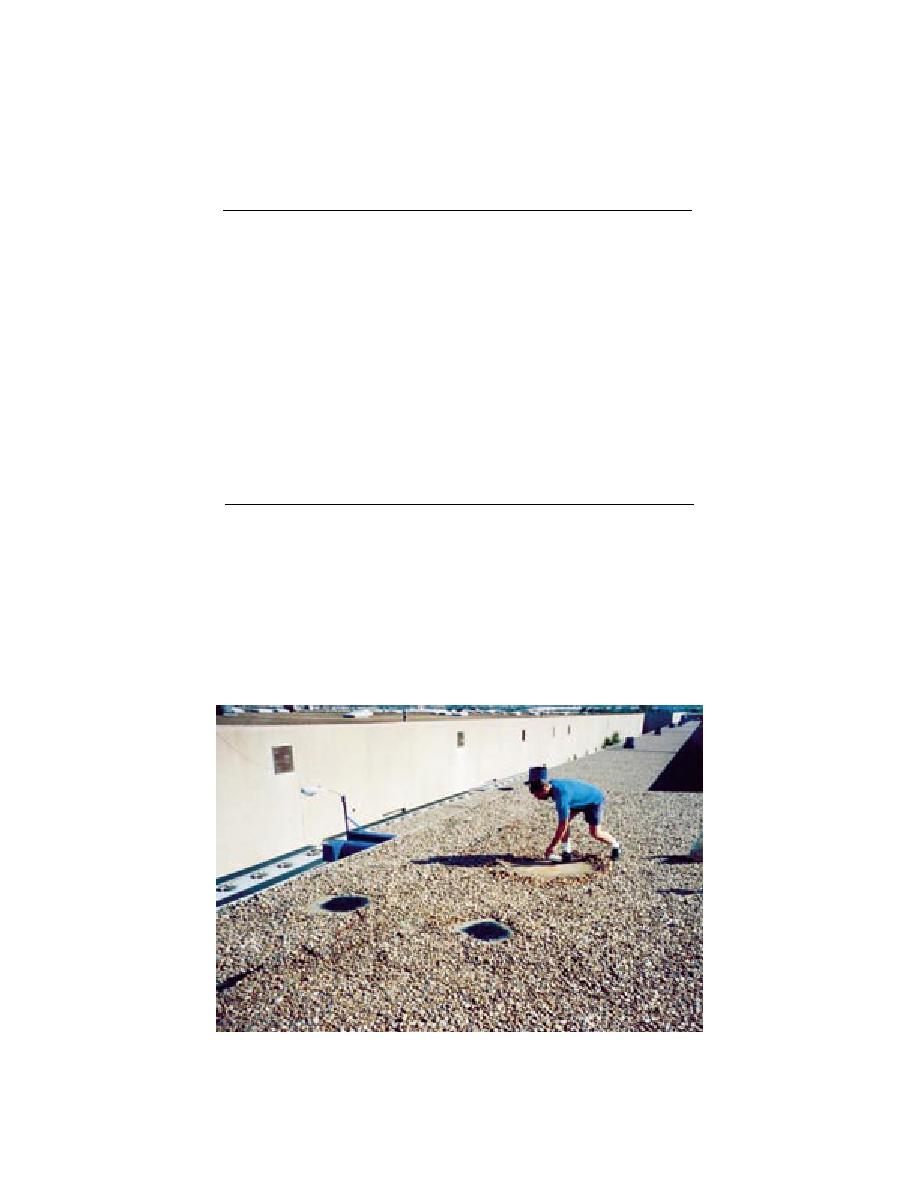

Figure 8. Southeast corner of roof D1 showing areas cleaned for cores 1 and 2 and

a larger area being prepared for core 8 and cut A, looking SE.

5

Previous Page

Previous Page