under those roofs are shown on that figure as are

the locations of all cores and cuts made on them.

Roofs D1D6 are interconnected by lower roofs

not shown in Figure 2. Figure 3 contains similar

information for the three roofs in Arlington (roofs

A1A3).

All roofs except D5 have a loose-laid ballasted

EPDM membrane. Roof D5 contains a loose-laid

ballasted Hypalon membrane. All Dallas roofs

except D7 contain an old bituminous built-up

membrane below. The new membranes were

added because the old ones were problematic. The

old membrane is directly below the Hypalon mem-

brane on roof D5. It is separated from the EPDM

membrane on roof D6 by half an inch (1.3 cm) of

wood fiber insulation and by 2 in. of expanded

polystyrene insulation on roofs D1D4. No old

membranes exist within the three Arlington roofs.

A number of different insulations exist within

these roofs: expanded polystyrene (EPS), extruded

polystyrene (XPS), isocyanurate (ISO), phenolic

(PHE), perlite (PER) fibrous glass (FGL) and wood

fiber (WOF).

Detailed information on each roof is presented

in the sections that follow.

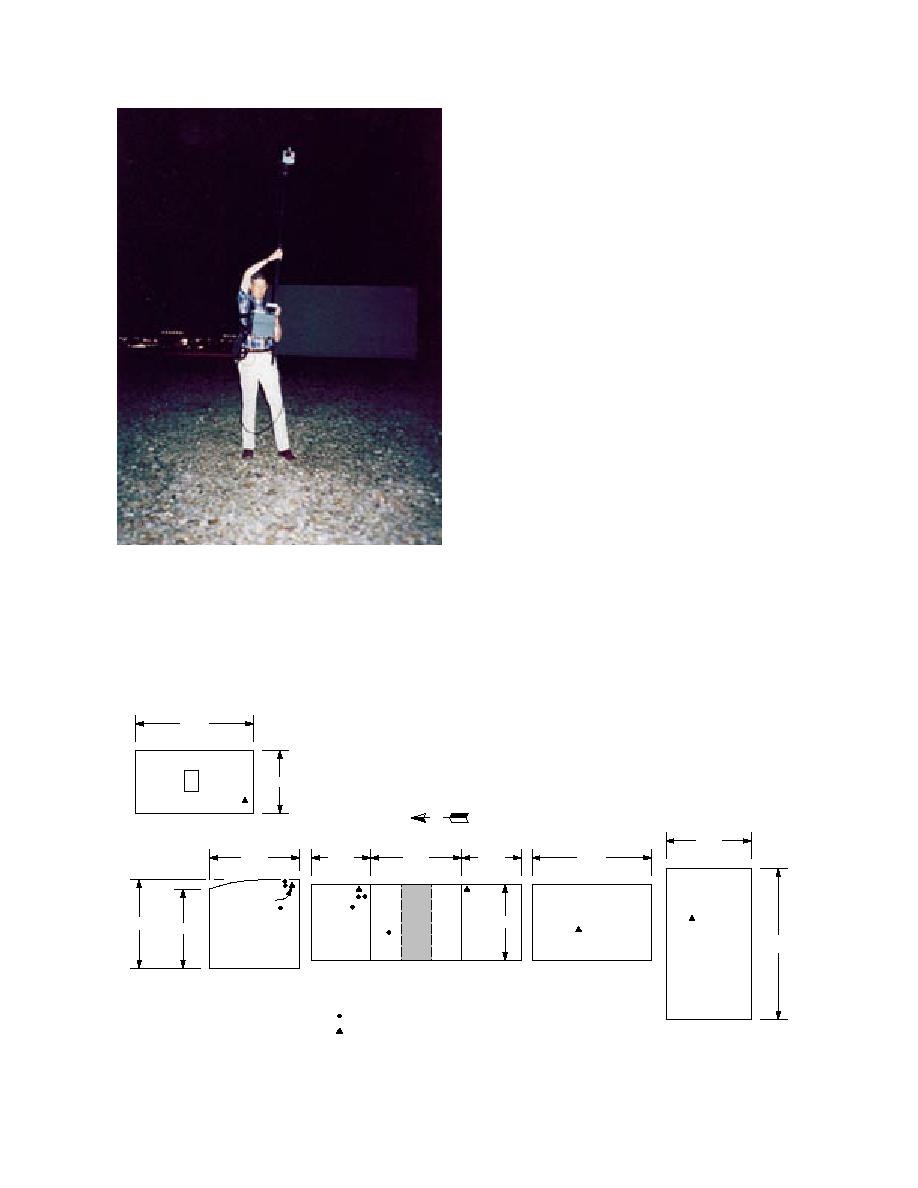

Figure 1. Conducting nighttime on-the-roof infrared

roof moisture surveys. We found it quite valuable to

observe the roof from as high a vantage point as pos-

ROOF D1

sible.

This roof consists of a ballasted EPDM mem-

brane, expanded polystyrene insulation (2 in.), an

old bituminous built-up membrane, fibrous glass

279 ft

134 ft

F & 11*

N

D-7

(18F)

175 ft

189 ft

128 ft

190 ft

128 ft

255 ft

1

B & 3*

2

6

C & 4*

A & 8*

7

12

13

E & 5*

159 ft

10

192 ft

170 ft

D & 9*

320 ft

D-2

D-3

D-4

D-5

D-1

(0F)

(0F) (38F) (0F)

(0F)

(0F)

(0F)

Core (2 in. diameter)

D-6

Cut (12 in. 12 in.) and Core (2 in. diameter)

(0F)

*Cuts are lettered; Cores are numbered.

Figure 2. Plan view of the seven roofs examined in Dallas, Texas.

2

Previous Page

Previous Page