Lock-in

amplifier

MTS

testing machine

IcIce

e

s

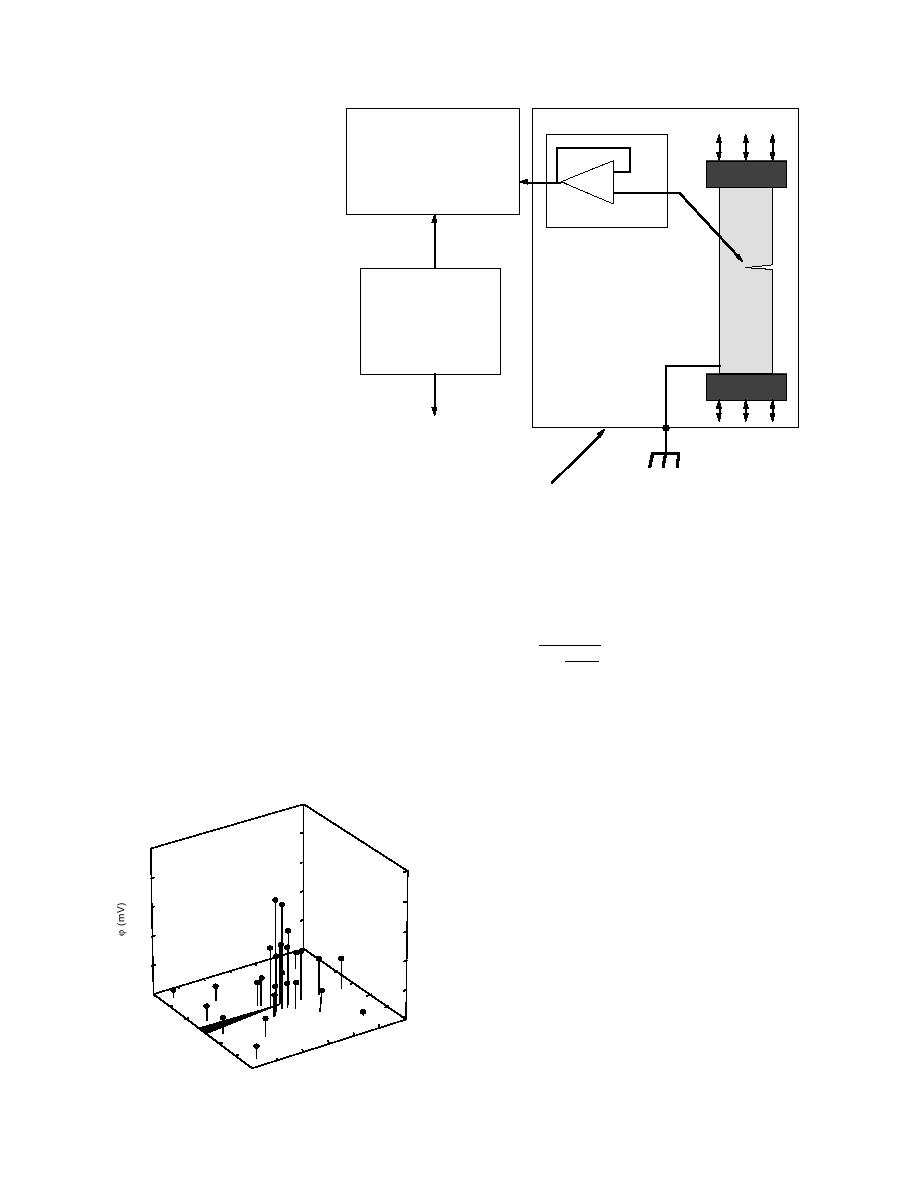

Figure 25. Schematic of experimental configuration used in

measurements of electric fields on the ice surface around a

stable crack (after Petrenko 1992a).

Shielded box

bandsaw (1 mm thick) were located in the middle of

Figure 26 shows the distribution of the amplitude of

an oscillating electrical potential ϕ measured around

the samples, perpendicular to their long side. Sample

dimensions were 15 6 6 cm3 and the crack length

an artificial mode I tearing crack. To compare these

experimental results with the theory, ϕ was calculated

varied from 5 to 30 mm. An oscillating sine wave, of

frequency from 1 to 300 Hz, was applied to the sam-

using eq 51

ples by an MTS testing machine. In this set of meas-

εiiα j

ϕ=

urements, a sine potential difference was measured by

(53)

Φεε0

ej +

a lock-in amplifier between one remote electrode

ej

mounted into the ice and one electrode placed near the

crack tip. This latter electrode in some cases was

where εii must be taken from eq 47 and αj = α4 = 6.2

mounted into the ice to a depth of 2 mm, by careful

eV (Evtushenko et al. 1987). There is satisfactory

heating of the electrode, or was attached to the ice sur-

quantitative and qualitative agreement between theory

face with slight pressure. The electrodes were made of

and experiment in the vicinity of the crack tip for r =

stainless steel wire of 0.1-mm diameter.

110 mm. At r = 1 mm, ϕ = 0.8 mV. Yet, at larger dis-

tances ϕ remains almost constant instead of decreasing

to 0 as the theory predicts (ϕ ∝ r 1/2; r is the distance

1.0

Sample dimensions 13 6.5 6.5 cm

0.8

Crack length l = 3 cm

Width d = 1 mm

0.6

T = 10C

0.4

Stress amplitude 0.12 MPa

Frequency 90 Hz

0.2

30

20

Figure 26. Amplitude of electric potential ϕ on the surface of

10

30

0

20

the ice sample measured in the configuration shown in Fig-

10

y

(m 10

0

m

ure 25; large grains of ice grown from deionized water (after

10

m)

)

20

x (m

20

Petrenko 1992a).

30 30

19

Previous Page

Previous Page