degradation was noticed. However, in the win-

Impact test

ters, the installation suffered severe snow accu-

An impact test of the 6.35-mm (0.25-in.) and

mulation and was subjected to snow plowing (Fig.

9.53-mm (0.375-in.) W-beam materials, designated

33); as a result, immediately after the first winter,

as CR2 and CR3, respectively, was conducted by

the surface veil coating was observed to be

Svenson (1993) at the Turner-Fairbank Highway

removed at several places (Fig. 34).

Research Center of the FHWA in conjunction with

their intensive studies of "Impact Behavior of

Composites." The results of the impact testing of

a number of commercially available pultruded

composites conducted using an MTS (Model

850.02A-01) vertical drop weight testing machine

were reported at the 1993 Annual Conference of

the Composites Institute, and readers are encour-

aged to read the article to review the detailed pro-

cedures of the test. The tests were conducted by

dropping a striking cylinder head perpendicular

to the specimen's broad surface at the center of a

simply supported span. Load (P), energy (E), and

velocity (v) were measured from the acceleration

history of the impact. For the striker weight w,

and acceleration a, these parameters were given

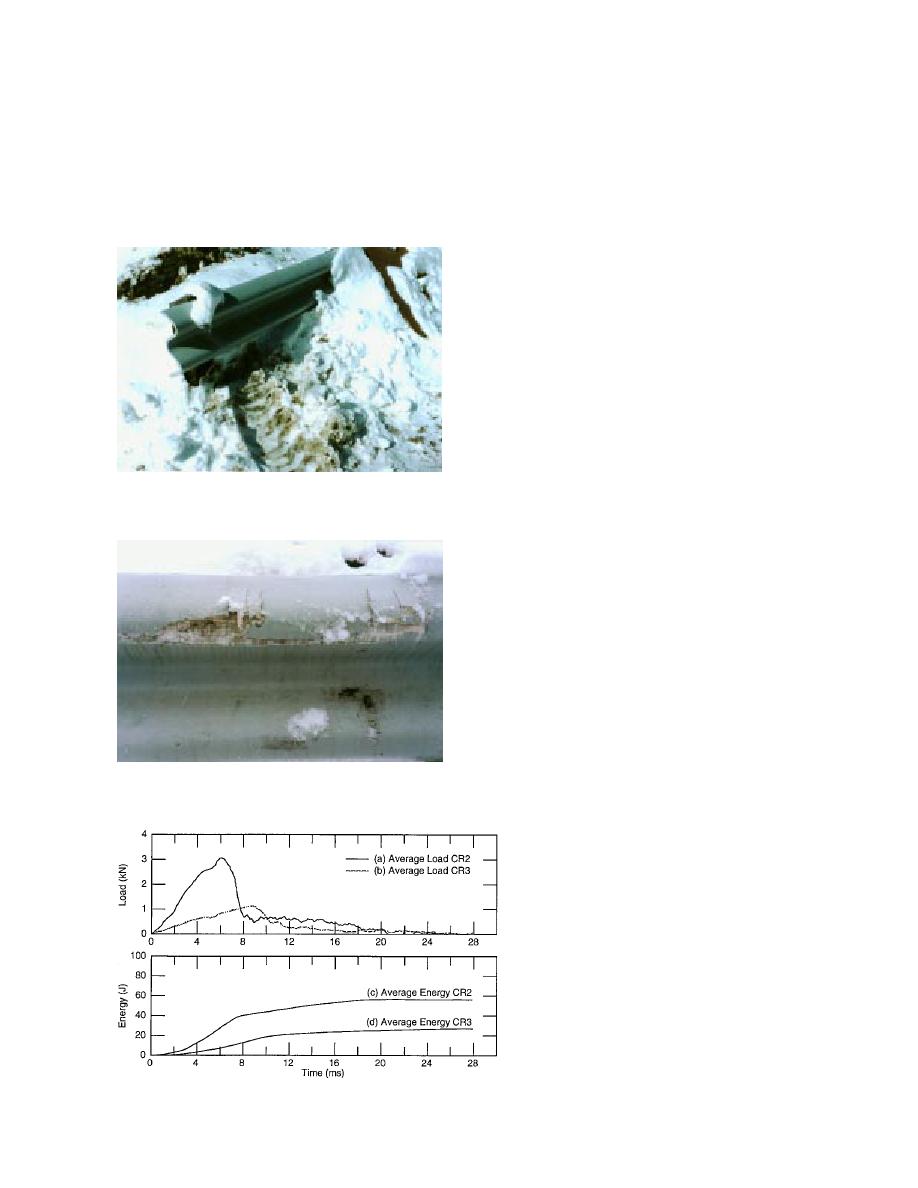

Figure 33. The FRP W-beam installation exposed to

by

heavy snow accumulation and plowing.

P = ma

(5)

v = g ∫ a dt

(6)

and

E = ∫ Pv dt.

(7)

To compare test results, such as load and energy,

from different specimens, the authors used a nor-

malizing procedure using the maximum elastic

bending stress equation:

σ = (2PLh)/(4I)

(8)

where σ = maximum bending stress

P = load

Figure 34. Snow plow abrasion damage to the FRP

L = length of the specimen

beam.

Figure 35. Average load-time history of (a)

6.35-mm- (0.25-in.-) thick CR2 and (b) 9.53-

mm- (0.375-in.-) thick CR3 specimens under

impact test. Average energy absorbed in (c)

6.35-mm- (0.25-in.-) thick CR2 and (d) 9.53-

mm- (0.375-in.-) thick CR3 specimens under

impact test.

23

Previous Page

Previous Page