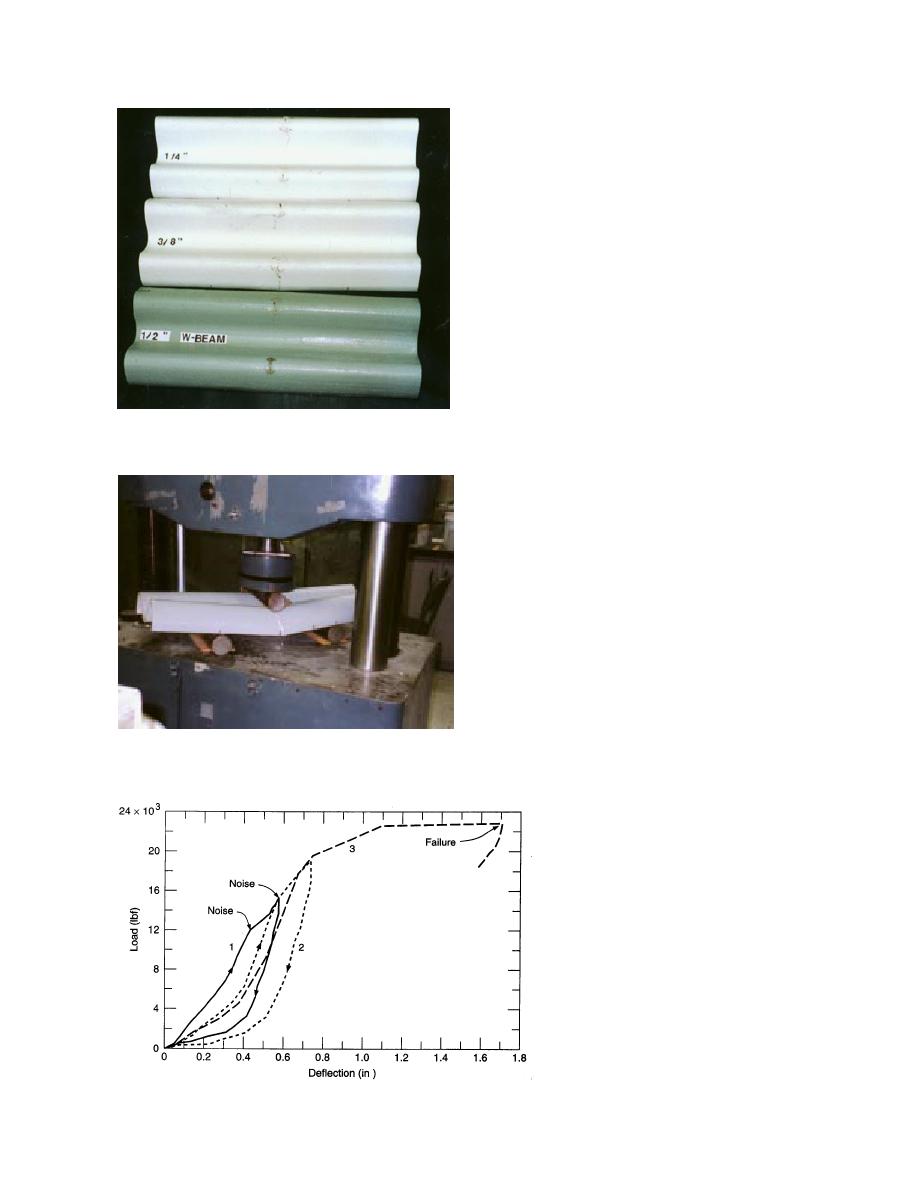

deflection characteristics for the four samples

plotted in Figure 28 clearly show large hyster-

esis, indicating energy absorption by internal

cracking. However, the beams maintained con-

siderable flexural stiffness after cracking, and

they bounced back to their linear shape after

the load was removed. In fact, the samples

shown in Figure 26 were all fractured in the test,

but the cracks practically closed on removal of

the load. Figure 29 summarizes the load deflec-

tion data from all samples. Failure strengths and

stiffnesses of the 6.35-mm (0.25-in.), and 9.53-

mm (0.375-in. beams were considerably lower

than those of the 12.7-mm- (0.5-in.-) thick beams,

and the thinner beams obviously deflected much

more for a given load.

Table 5 is a summary of the critical data from

these tests along with the data initially obtained

Figure 26. Three FRP W-beam samples for three-point

for the steel W-beam. Table 5 clearly shows that

flexure tests.

the 12.7-mm (0.5-in.) W-beam exceeds the per-

formance of the steel W-beam in yield strength

by about 42%, but its flexural stiffness (EI) is only

34% of that of steel. It also weighs approximately

87% of the steel beam. If a lower stiffness is

acceptable, the 12.7-mm (0.5-in.) W-beam can be

a candidate for a one-to-one replacement of the

steel W-beam. The 9.53-mm (0.375-in.) and 6.35-

mm (0.25-in.) W-beams obviously have much

lower flexural stiffnesses, but they also have

about 86% and 43%, respectively, of the strength

of the steel beam. Their weights are also only

68% and 47%, respectively, of the steel beam.

Cold weather exposure test

Although this exploratory development of an

FRP W-beam guardrail was far from viable and

Figure 27. Three-point flexural test configuration for the

acceptable as a proper guardrail for highways,

FRP W-beam samples.

Figure 28. Load-deflection characteristics

from cyclic loading of 12.7-mm (0.5-in.)

thick W-beam.

.

21

Previous Page

Previous Page