CHAPTER 4: RECYCLED PLASTIC COMPOSITE GUARDRAIL POSTS

Commercial production of synthetic lumber

carded into the solid waste stream (Miller and

from recycled plastics has been reported both in

Johnson 1989), and because plastic wastes occupy

the U.S. and abroad. Many of these recycled plas-

more volume than other solid wastes, it is esti-

mated that thermoplastic solid waste will occupy

tics are mixed with other ingredients, forming

about 80% of the available space. As a result, the

composites, and are being marketed as structural

recycling of plastics is gaining momentum and

materials. The thrust of the research presented

the uses of re-formed plastics are proliferating.

here is a study of the mechanical characteristics

A potentially large volume application of recycled

of one such recycled plastic composite (RPC),

plastics in guardrail applications will help the

which appears to have the potential for applica-

national plastic waste recycling effort. Second,

tion as the guardrail posts and blockouts.

existing creosote treated wooden guardrail posts

Guardrail system designs rely primarily on the

are not favored by many environmentalists,

soil bearing capacity to yield to impact, but the

because of the potential danger of groundwater

posts provide enough restraining force to redi-

contamination by leached creosote. Such dangers

rect errant vehicles. Typical wooden posts made

will be minimized if the substitution of wooden

from Douglas fir, hemlock, etc., have a rupture

posts and blockouts by RPC becomes possible.

strength (equivalent to the stress at which the

In addition, the availability of lumber through-

fibers will fail in tension under bending load) that

out the world is greatly diminishing as a result of

varies from 41.34 MPa to 82.68 MPa (6000 to

a significant international effort to preserve the

12,000 psi) and a modulus of elasticity of from

8.96 GPa to 13.78 GPa (1.3 l06 to 2 l06 psi). To

rain forests. An alternative material like RPC for

guardrails will reduce the demand on the pres-

develop enough restraining force to redirect errant

sure-treated lumber supply.

vehicles, the impact response characteristics of an

RPC post system would need to be in the same

range as those of a wooden post.

Initial survey and

There are two attractive features that favor con-

material identification

When this study was initiated, a survey of

sideration of recycled plastic composites (RPC)

the U.S. marketplace showed that recycled,

for highway structures. Both these features relate

mixed plastics were being used for noncritical

to the overall improvement of the quality of our

load-bearing applications such as park benches,

environment. First, as landfill space becomes

picnic tables, fences, curbs, parking blocks, etc.

increasingly scarce, the satisfactory disposal of

However, it was noticed that a large percentage

solid waste is becoming a critical issue. By the

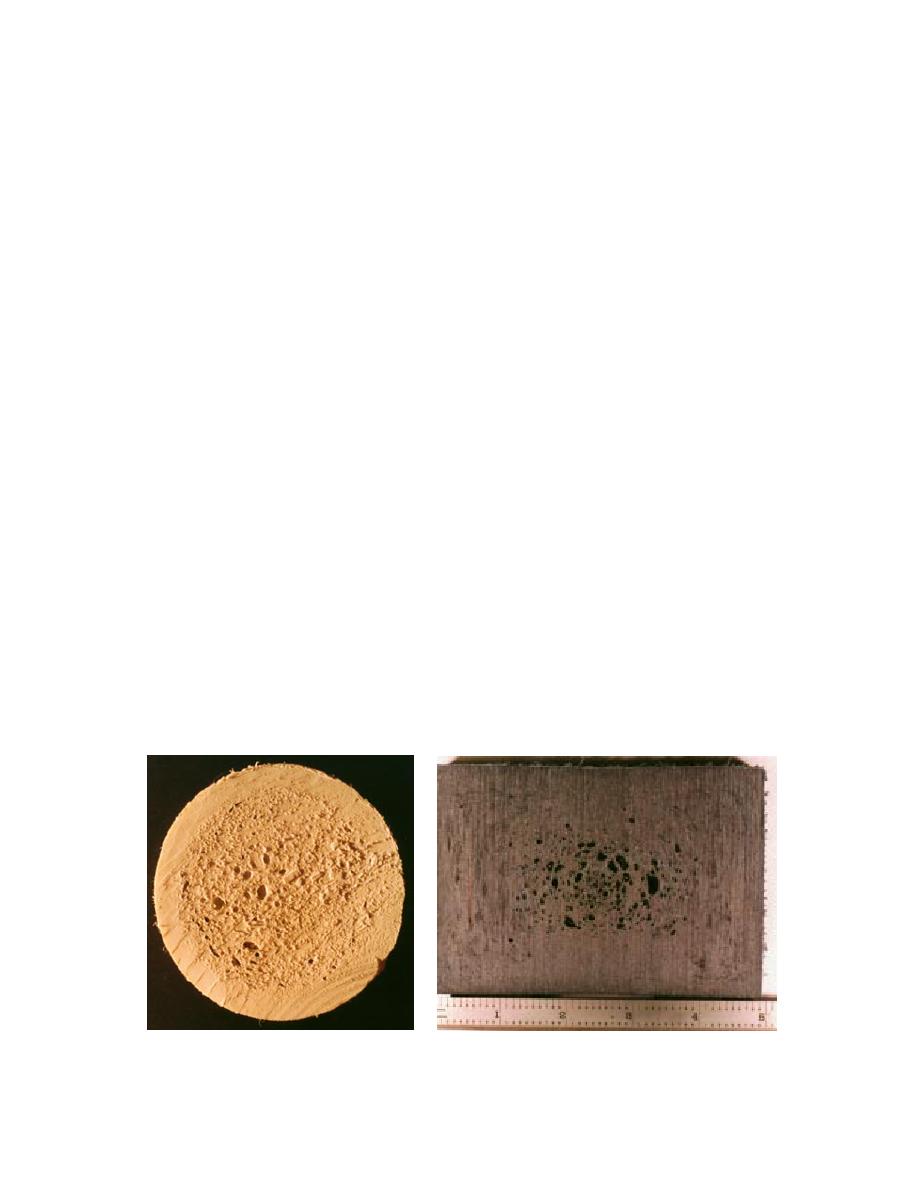

of this "plastic lumber" contained cavities (Fig.

turn of the century, an estimated 37 billion kg (80

37) in the central region of the cross section. The

billion lb) of thermoplastic waste will be dis-

a. Manufacturer A.

b. Manufacturer B.

Figure 37. Commercial plastic lumber containing cavities in the core area of the section.

26

Previous Page

Previous Page