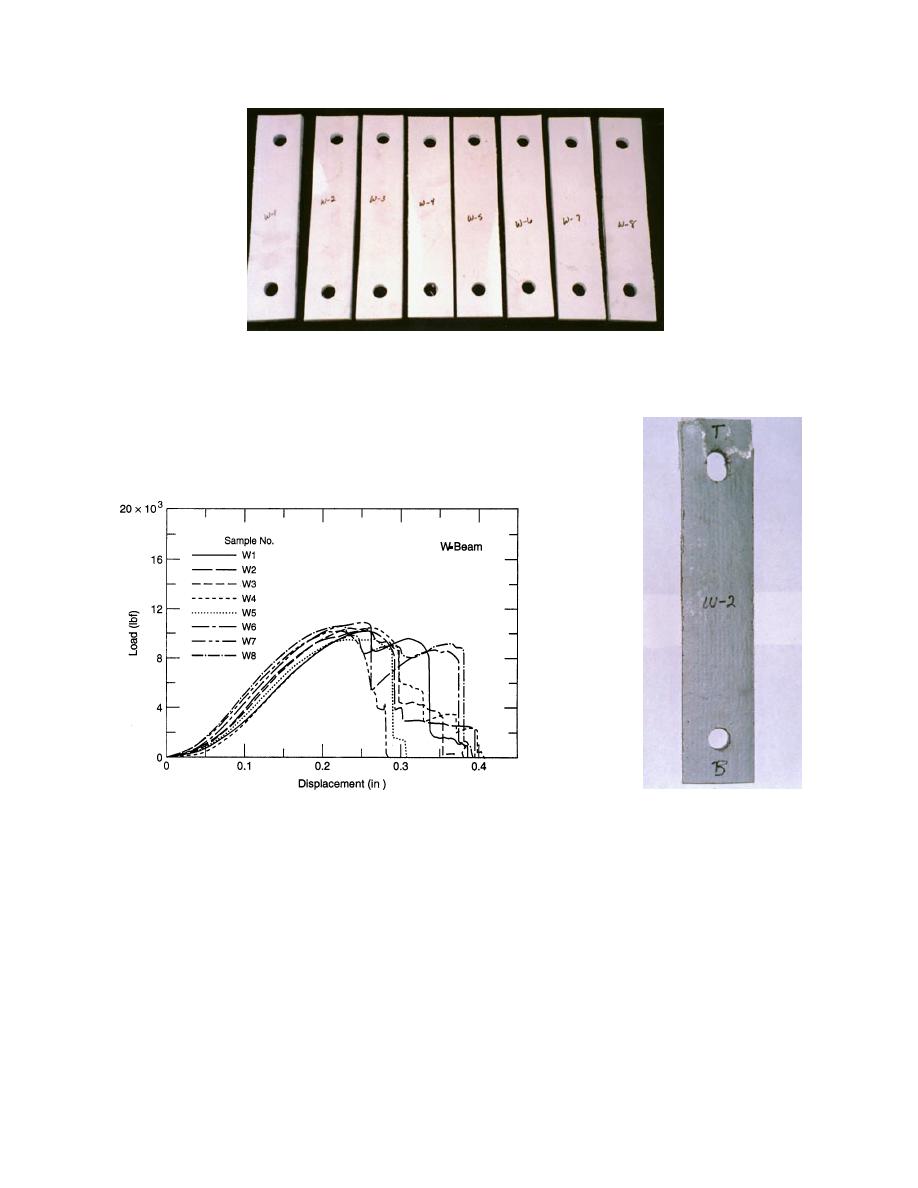

Figure 23. FRP W-beam test coupons for 19.05-mm (0.75-in.) bolt

pull-out tests.

.

Figure 24. Load-displacement curves from the bolt pull-out test.

Figure 25. Failed specimen

from the bolt pull-out test.

manually. The 12.7-mm (0.5-in.) samples 1

Flexural tests

through 3 were loaded to failure, when fracture

As in the initial tests, flexural tests were con-

occurred at the point of contact with the loading

ducted on all three composite beams shown in

bar. Sample 4, however, was loaded cyclically, first

Figure 26. Four samples (designated as sample 1

to 66.75 kN (15,000 lbf), then unloaded to 1.11 kN

through 4) were prepared from the 12.7-mm- (0.5-

(250 lbf), reloaded to 84,55 kN (19,000 lbf),

in.-) thick beam and one each from the 9.53 mm

unloaded to 1.11 kN (250 lbf), and finally loaded

(0.375 in.) (sample 5) and 6.35 mm (0.25 in.)

to 100.13 kN (22,500 lbf), when it severely cracked

(sample 6) beams. The three-point test configura-

but continued to deflect to 43.18 mm (1.7 in.).

tion is shown in Figure 27. The load was applied

During loading, low-level cracking noise was

using the screw testing machine, as in the initial

heard in each of the four samples. The load

tests. The loads and deflections were recorded

20

Previous Page

Previous Page