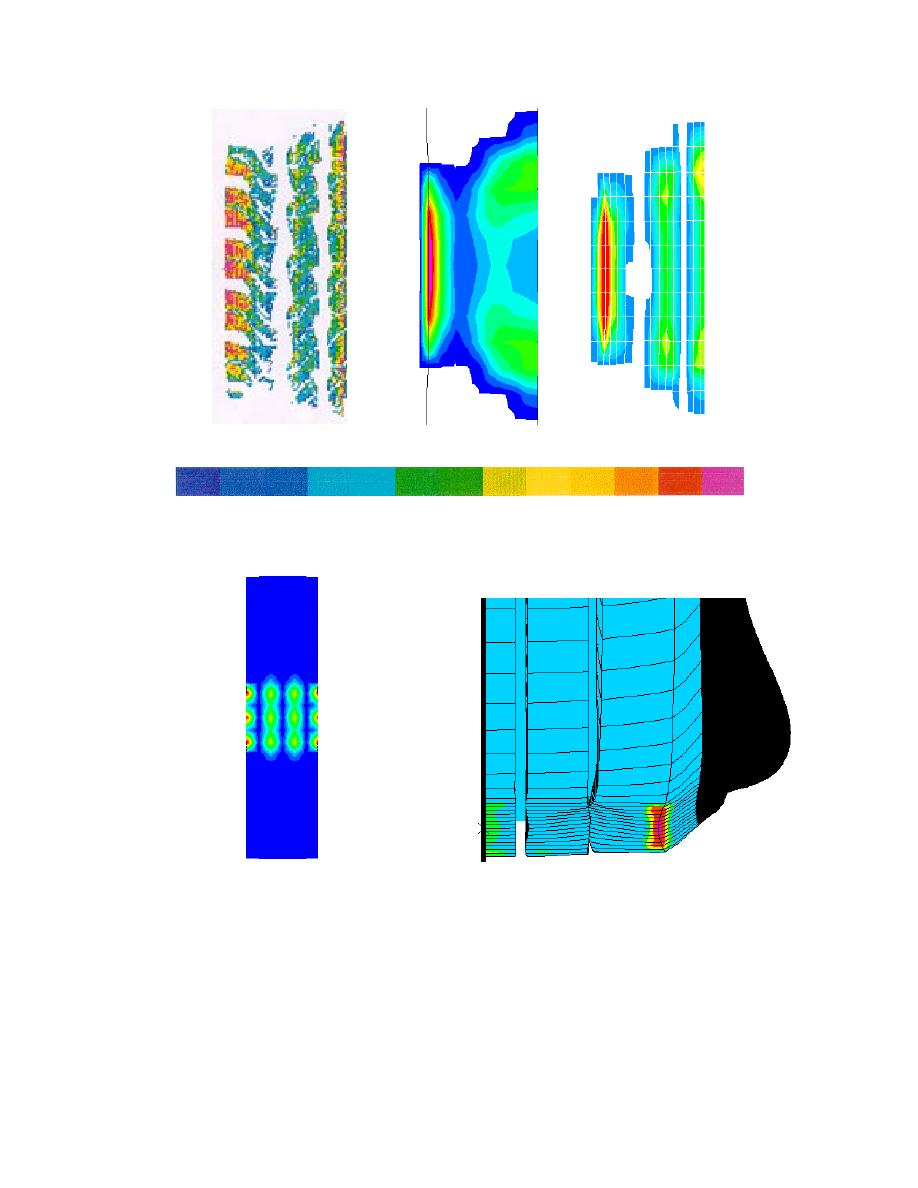

Measured

Smooth tread model

Ribbed tread model

7

69

131

193

262

324

386 448

510

572

641

703

765

kPa

Figure 52. Measured and modeled contact stress distribution for half carcass on a hard surface

(207 kPa inflation and 6627 N load).

Figure 54. Close-up view of the contact for the

Figure 53. Irregular stress contours generated by

ribbed tire model, showing buckling just inside

the ShoopDarnell model on a rigid surface (full

the shoulder area (half tire carcass).

carcass width).

gressively finer meshes fail to converge [similar be-

During contact on a rigid surface, the Shoop

havior was noted and explored by Alvarez Sanz

Darnell model suffered from buckling just inside the

(1999)]. The buckling behavior also occurs to a lim-

tire shoulder area, which strongly affected the contact

ited extent in the physical tire and in the modal

stress. Although a finer mesh would normally smooth

analysis tire models (seen in the contours in Figure

the contact stress contours, the buckling causes alter-

52). The buckling is worse at low inflation pressures

nate nodes to lift off the surface, resulting in the

and high loads (Fig. 54). The impact is minor for the

stress pattern shown in Figure 53. Eventually, pro-

39

Previous Page

Previous Page