snow, reflected in the hardening table, has the great-

est influence on resulting tire forces and sinkage.

Changes to the acceleration, velocity, and friction

coefficient have little effect on model results, partly

because of the low velocities and accelerations in-

volved in standard snow rolling resistance tests.

Motion resistance forces and sinkage

The tiresnow model was compared to field

measurement of tire forces made with an instru-

mented vehicle. Model results were also compared to

rolling resistance and sinkage predictions made from

established algorithms for snow (as adopted by the

NATO Reference Mobility Model).

Experimental measurements. Vehicle performance

was measured using the CRREL Instrumented Vehi-

cle (CIV), which is instrumented to measure vertical,

longitudinal, and lateral forces at the tireterrain in-

terface; wheel speed at each wheel; true vehicle

speed; and steering angles. The CIV is designed as a

research tool to perform various mobility tests (trac-

tion, resistance, and maneuverability) using different

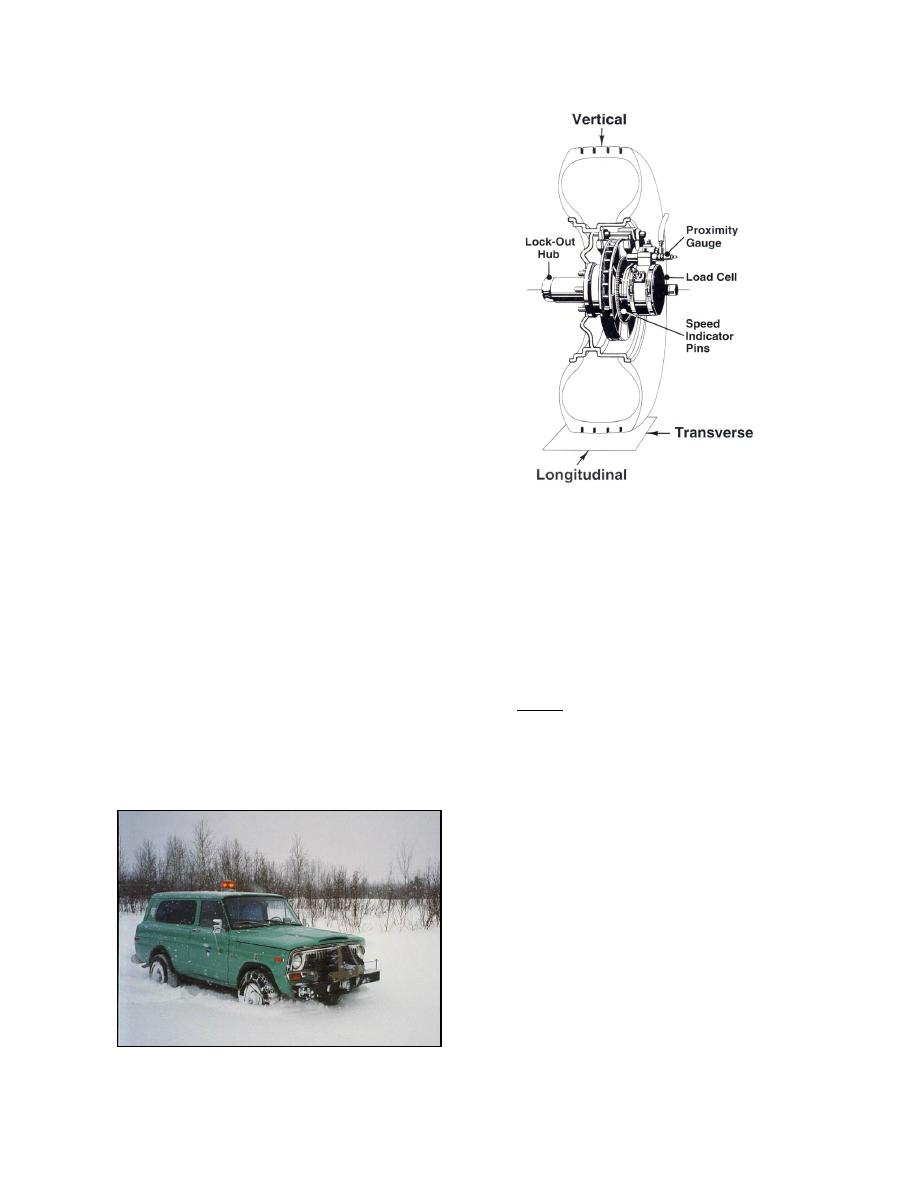

Figure 59. Configuration of speed

tires, traction aids, and vehicle configurations (of

sensors and axle-mounted load

braking and driving wheels) on a range of terrain

cells on the CIV (From Shoop et al.

surfaces including dry, wet, snow, ice, and freezing

1994.)

or thawing ground. The data obtained from these tests

on the vehicle. The difference between the wheel

are used for model validation and for developing al-

speed vw and the vehicle speed vv is termed the dif-

gorithms to predict vehicle performance on cold-

ferential interface velocity (DIV), also called the

weather terrain.

"slip speed" or "longitudinal slip velocity" (SAE

The vehicle, originally a 1977 American Motors

1992). This is often normalized by the speed of the

Corporation Jeep Cherokee, is shown in Figure 58.

vehicle and called slip i (ISTVS 1977):

Each wheel is instrumented with a three-component

load cell (Fig. 59), designed and calibrated to respond

vw - vv

i=

100% .

(28)

to the forces at the terrain interface. The wheel speed

vv

is measured using a proximity sensor with a set of

Using this convention, driving slip is positive and

100 measurement pegs set into the brake rotor. Wheel

braking slip is negative.

speed is compared to the true vehicle speed measured

Rolling resistance or motion resistance is the sum

using a fifth wheel or a sonic speed sensor mounted

of the forces resisting vehicle motion. These are

forces due to the internal friction of the moving parts

of the vehicle, the air drag, the internal resistance of

the tires due to flexing of the belts and plies and vis-

cous properties of the rubber compounds, and the

added resistance due to the deformation of the sur-

face. The CIV measures motion resistance forces

directly at the wheel, eliminating the forces acting on

the vehicle body. Motion resistance is tested with the

CIV by rolling the vehicle through snow at a constant

speed. The vehicle is driven with the rear wheels

only, and the front brakes are released so that the

only forces on the front wheels are due to the tires

and snow. The internal resistance of the tire is meas-

ured by rolling it on a hard surface. This value is sub-

tracted from the snow motion resistance measure-

Figure 58. The CRREL Instrumented Vehicle (CIV).

44

Previous Page

Previous Page