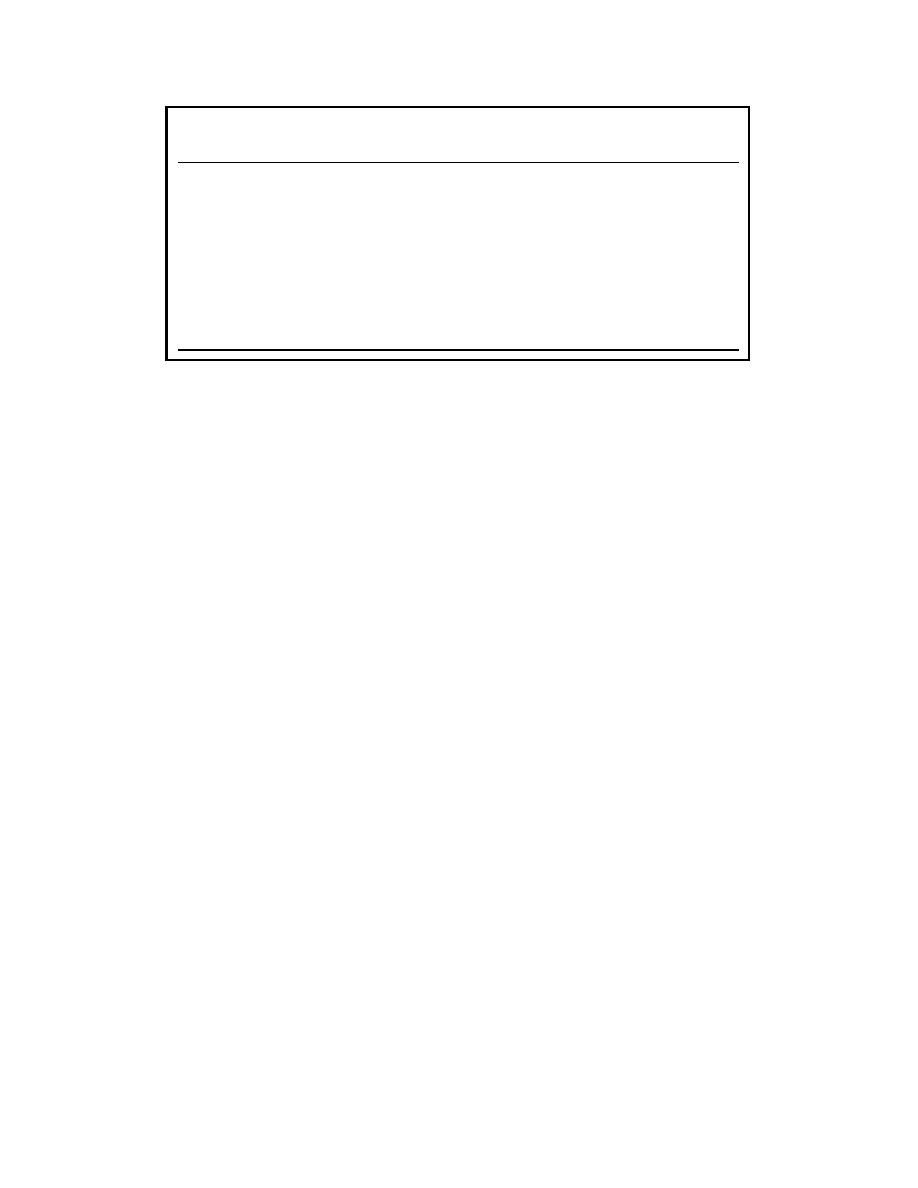

Table 10. Qualitative summary of runtime analysis.

Model parameters compared

Change in performance

Static vs. dynamic analysis

Static models rolled 2 m vs. 0.08 m before conver-

gence problems

Half tire carcass vs. full tire carcass

Half tire runs three times faster

Smooth vs. ribbed tread model

Smooth model runs four times faster

SGI Octane vs. Cray J932

Octane is two to three times faster

Tight vs. loose convergence controls

Loose controls run faster but tight controls let the tire

roll further before convergence problems

Example run times

Ribbed tread, full tire, tight convergence

Rolls 25 mm in 488 hr on J932

Ribbed tread, half tire, dynamic analysis

Rolls 46 mm in 252 hr on J932

Smooth tread, half tire, static analysis

Rolls 2 m in 22 hr on Octane

ShoopDarnell model (full tire)

Roll 20 m in 11 min on Octane

COMBINED TIRETERRAIN MODEL

run time. It takes almost three times as long as the

half-tire model to go the same distance. No full-tire

Modeling the tireterrain contact interface

model has stopped due to non-convergence, but

rather due to system errors or time limits. In the fu-

Contact

ture, if side forces, cornering forces, or steering reac-

To merge the tire and terrain models, the interface

tions are investigated, then a full-tire model will be

between the two meshes must interact. This is ac-

required.

complished by defining where contact is allowed,

Smooth tread vs. ribbed tread. The model with the

how the contact occurs, and how forces are transmit-

smooth tread has fewer nodes and elements, is less

ted. For two meshes to come into contact, a surface

geometrically complex, and uses default convergence

must be placed on each material. For a deformable

controls. It runs more than four times faster than the

tire on snow or soil, one surface covers the outside of

ribbed tread model during the static analysis and

the tire and another surface lies on the top of the ter-

more than eleven times faster for the dynamic analy-

rain layer. The contact is defined by the proximity of

sis. In most instances the accuracy of the smooth

the surfaces. When both material meshes are deform-

model is as good as or better than the ribbed model

able, one surface is chosen as a "master" surface and

(i.e. the model results are closer to the experimental

the other as a "slave" surface. The more finely

data). In the dynamic analyses the smooth tread

meshed surface is usually chosen as the slave since

model went almost twice as far as the ribbed tread

the nodes on the slave surface are not allowed to

model.

penetrate the master surface.

Cray J932 vs. SGI octane. The models are being

Contact can be enforced using either "penalty" or

run on an SGI Octane (Intrepid, 120 megaflop) and a

"kinematic" contact methods. Both methods were

Cray J932 (Chilkoot, 12 CPU at 2.4 gigaflop each,

used. Penalty contact was implemented for pseudo-

200 total if optimized for this platform). Generally

static analyses, where inertia forces were not consid-

the same models took two to three times longer to run

ered. In penalty contact the penetration of the sur-

on the Cray J932 than on the SGI Octane. This is

faces into each other is resisted by linear spring

likely because HKS (the ABAQUS software devel-

forces with values proportional to the distance of

oper) uses the SGI as a development platform, which

penetration. These forces pull the surfaces into an

results in increased efficiency on that equipment.

equilibrium position with no penetration. Kinematic

Convergence controls. For the static analysis

contact was used in some of the dynamic simulations

ribbed tire model, the tire is maneuvered in several

(using the explicit code). Kinematic contact considers

steps, with the convergence controls adjusted at each

the inertia forces of the material when calculating the

step to increase efficiency. The loose convergence

forces relative to the surface positions. Although the

controls will allow the model to run faster, but con-

overall model results were the same with both contact

vergence stops after rolling only a short distance. For

methods, the kinematic contact was slightly more

dynamic rolling the model using the default conver-

representative of field observations of the snow de-

gence controls runs faster, and the tire rolls three

formation beneath the wheel (Haehnel 2000).

times farther, than when convergences controls are

looser or tighter than default values.

41

Previous Page

Previous Page