These models were configured for both implicit

mesh, therefore, does not directly reflect the deforma-

dynamic analysis and explicit dynamic analysis. The

tion of each element, as in a standard finite element

explicit models used ALE meshing, where the mesh

mesh, because the nodes and elements have moved

automatically adjusts during the deformation by al-

relative to the snow mass. However, the final surface

lowing mass transfer between elements. The final

shape is correctly represented, and tracer nodes can

be used to track the mass movement. The ALE mesh-

ing significantly reduces model run time (from over

48 hours to approximately 24 hours on an SGI Ori-

gin), eliminates severe mesh distortion, and smooths

the resultant load response, but it does not affect the

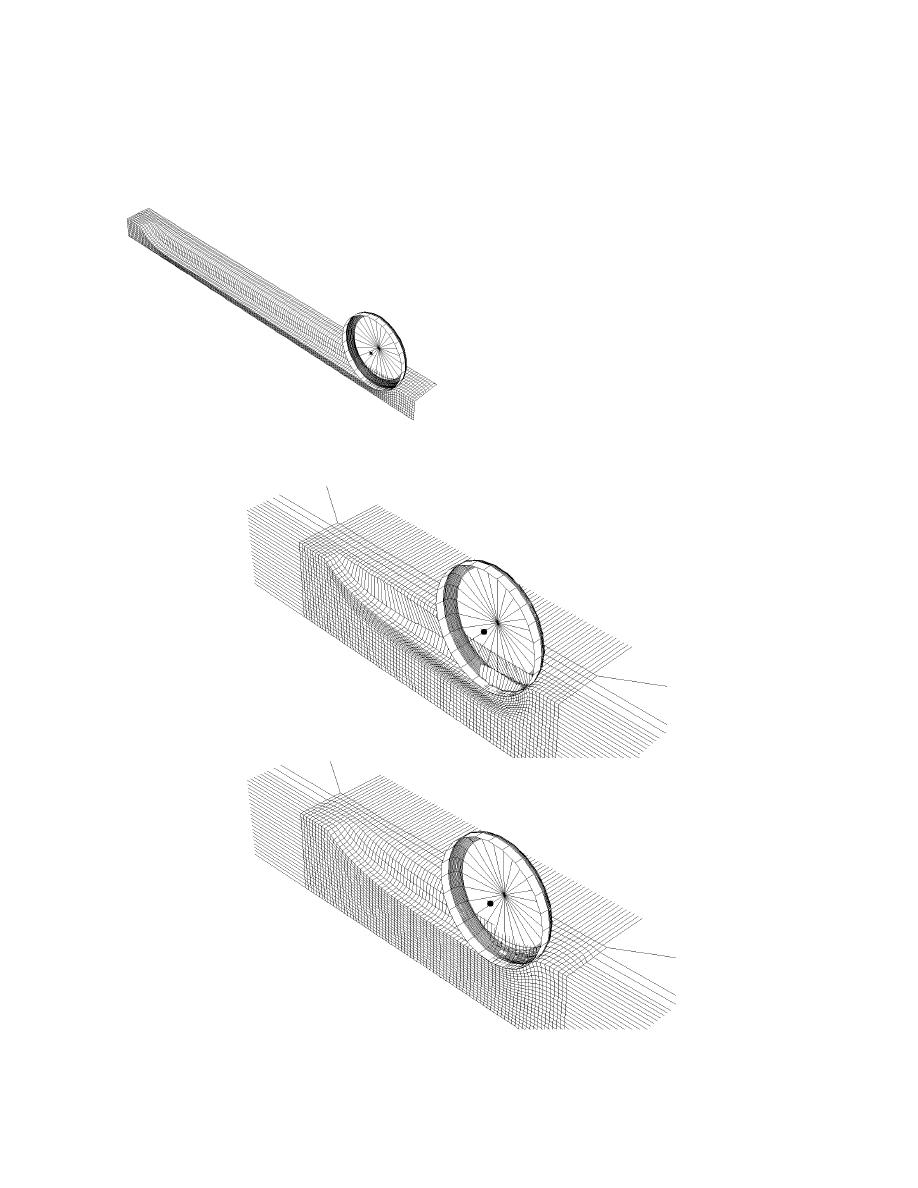

numerical results. Figure 57 shows the deformed

mesh for the deep snow model with and without the

ALE meshing.

The snow material properties were adjusted to

match field measurements of sinkage and motion

resistance. This was done primarily through changes

to the cap hardening and consequent adjustments

to the DruckerPrager parameters. Since snow com-

Figure 56. Model of a wheel rolling on 20 cm of

paction is the primary mechanism contributing to

fresh snow (infinite elements not shown).

motion resistance, the pressurevolume relationship for

Figure 57. Comparison of standard mesh (top) and ALE mesh (bot-

tom). (From Shoop et al. 1999.)

43

Previous Page

Previous Page