Tread Rubber

Belt

Belt Cushion

Inner Liner

Sidewall Rubber

Ply

Filler

Bead

Rubber Chafer

Apex

Bead

Filler

Wrapping

Bead Wires

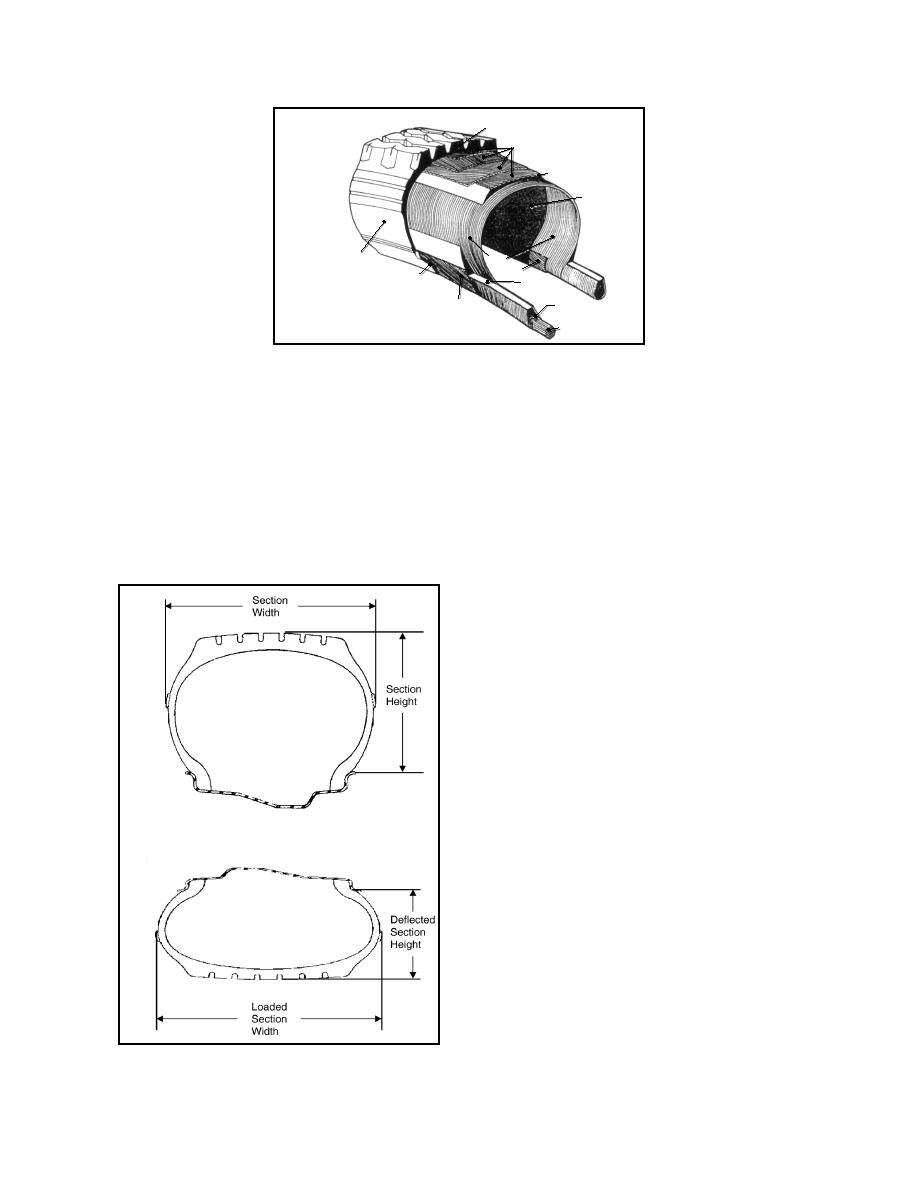

Figure 7. Construction components of a radial ply tire.

(After Goodsell 1995.)

TERRAIN MATERIAL MODELS

Tire deflection is a primary measure of the tire

structural response to load and is often reported based

on inflation pressure and vertical load. Deflection is

Terrain substrate subjected to vehicle loads has

the difference between the unloaded and the loaded

been represented using a wide variety of material

section height (and is sometimes reported in percent-

models, including elastic, non-linear elastic, visco-

age, normalized by the unloaded section height). The

elastic (Pi 1988), and elastic-viscoplastic (Saliba

tire cross section and the deformation of the cross sec-

1990). Recent studies have concentrated on using

tion under load are illustrated in Figure 8. A thorough

either cap DruckerPrager plasticity (Aubel 1993,

discussion of tire mechanics is given in Clark (1981).

1994, Fervers 1994) or critical state models such as

the Bailey and Johnson (1989) soil compaction model

implemented by Foster et al. (1995) or a new critical

state model (similar to Lade and Kim 1995) imple-

mented by Liu and Wong (1996). Comparisons be-

tween the DruckerPrager and Camclay models for

tireterrain interaction have been published by

Meschke et al. (1996) for snow and by Chi and

Tessier (1995) for soil. Although the Camclay

model is perhaps the most widely used soil model,

both of the above studies comment on convergence

problems when using Camclay. The choice of mate-

rial model is based on balancing the type of behavior

desired in the model with the information available to

determine model parameters. The terrain materials

simulated in this study were fresh snow and com-

pacted sandy soil. The two material models used

were a modified DruckerPrager with a cap, and a

critical state, crushable foam model. Both models

were considered suitable for capturing the highly

compressible behavior of natural fresh snow. The

compacted sand was modeled using the modified

DruckerPrager cap only. A description of these

models, model parameter determination, and valida-

tion of the material models with test data follows.

General concepts for plasticity models

The purpose of a plasticity model is to define the

Figure 8. Measurement of tire dimensions.

permanent deformation of a plastic material. This is

5

Previous Page

Previous Page