M = slope of the critical state line in the pq

plane, which controls the shape of the

yield ellipse

recoverable strain

ν = Poisson's ratio.

The following sections explain the Drucker

Prager cap model and the crushable foam model in

more detail.

Modified DruckerPrager cap model

For the modified DruckerPrager cap model used

in this study, the yield surface is a modified von

Mises yield (i.e., the material constant K = 1.0),

which is circular in the deviatoric plane (Fig. 9). In

the pt plane the yield surface has two major seg-

ments: the DruckerPrager shear portion of the curve

(analogous to the MohrCoulomb line) defines shear

deformation, and the cap portion of the surface de-

fines the intersection with the pressure axis (Fig. 17).

The following equations define the yield criteria in

each section of the yield surface.

For the DruckerPrager shear or distortional fail-

ure:

Fs = t - p tan β - d = 0 .

(12)

For the cap region of compactivedilatant failure:

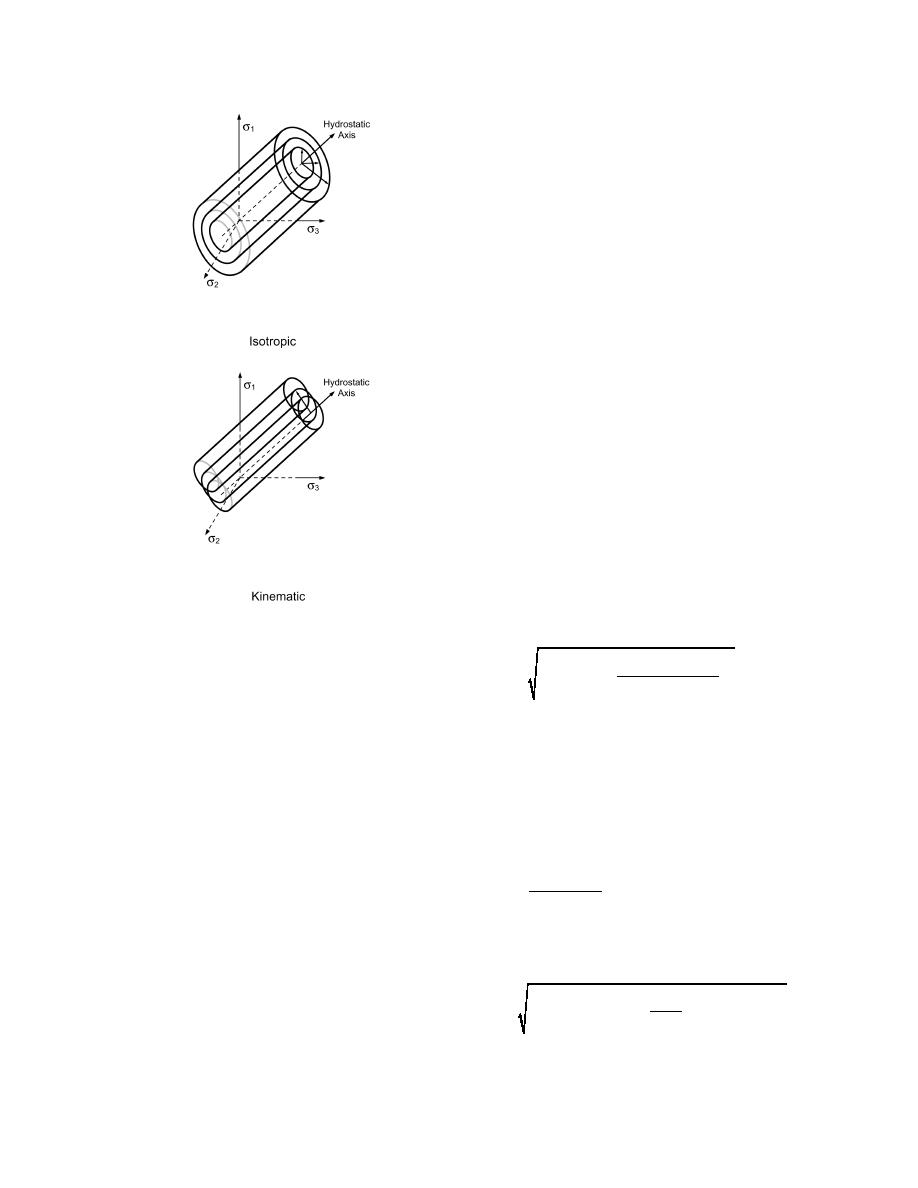

Figure 16. Isotropic and kine-

matic hardening. (After Shen

and Kushwaha 1998.)

2

Rt

( p - pa )

2

Fc =

+

(1 + α - α / cos β)

(13)

Parameters

A relatively small number of parameters are

-R (d + pa tan β) = 0

needed for these material models. Although more

detailed models may provide a more accurate solu-

where α is a transition parameter, ranging typically

tion, the parameters needed to define the model

from 0.0 to 0.05, that smooths the transition between

become prohibitively numerous and are often un-

the shear failure and the cap failure, R is a material

available. The objective of any model is to capture

parameter controlling the cap eccentricity, and pa

the most important material behaviors without being

defines the evolution of the cap along the pressure

unduly cumbersome. The following descriptions of

axes (via pbεvol hardening law) according to

the material parameters are based on the models as

implemented in ABAQUS (HKS 1998). Additional

pb - Rd

information on soil plasticity and critical state soil

pa =

.

(14)

(

1 + R tan β)

mechanics is given in Wood (1990).

The model parameters used in this study are:

The transition between the shear and the cap fail-

d = DruckerPrager material cohesion

ure is

β = DruckerPrager material angle of friction

λ and κ = slopes of the loading (compression) and

2

α

( p - pa )

(d + pa tan β)

unloading (elastic) lines in the compression

2

Ft =

+ t - 1 -

cos β

plane as indicated in Figure 14. This hard-

ening or softening of the material can also

-α (d + pa tan β) = 0 .

be defined in a piecewise manner (Fig. 15).

(15)

10

Previous Page

Previous Page