10

Run 2

Run 3

Porous Plate

8

6

K = 1 1018

4

K = 4 1019

2

0

30

0

6

12

18

24

Days

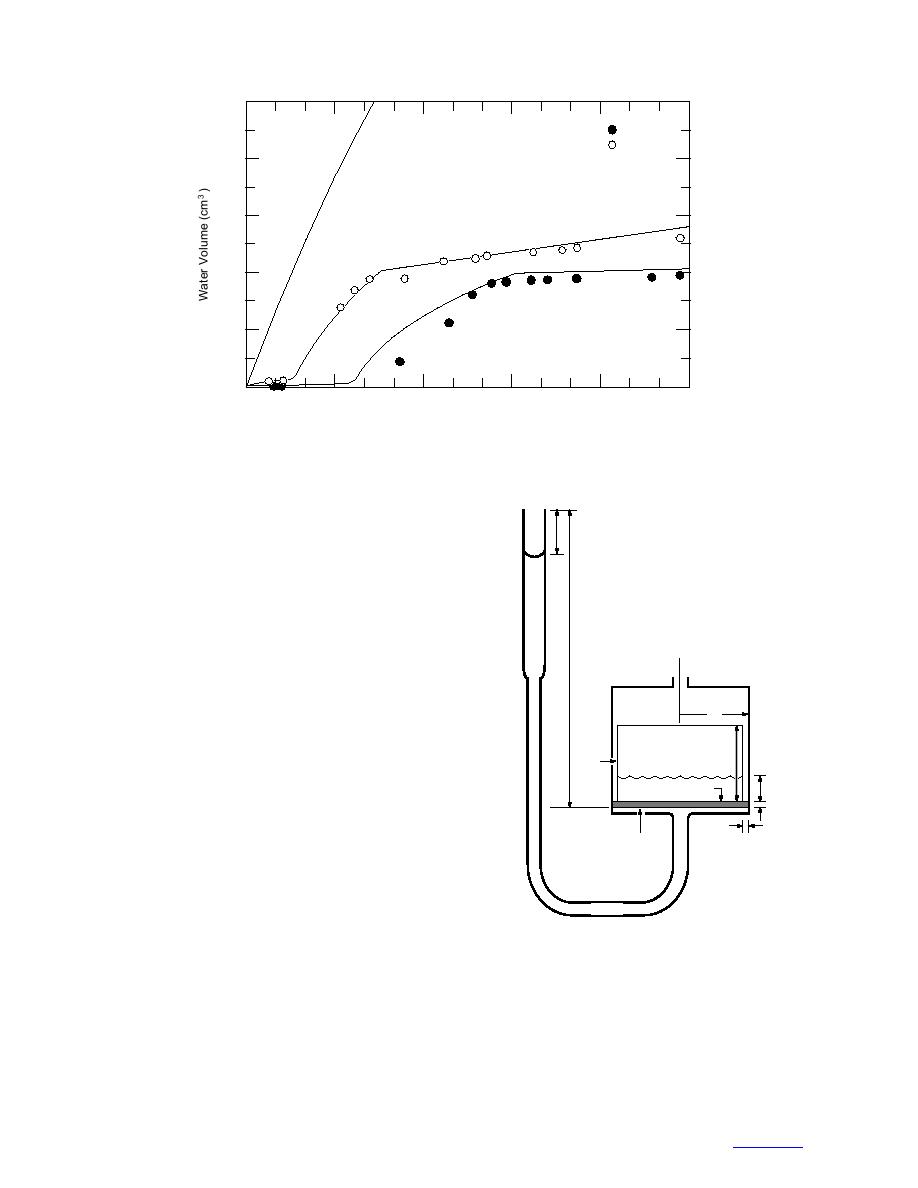

Figure 11. Days vs. volume of water re-entering Sample B. Solid circles are for

run 2 and open circles for run 3. Lines show computed flow rates for the porous

plate alone and for hypothetical configurations of the ice sample.

on Sample B. Gauge pressure had been reduced to zero,

but the height of water in the pipette created a pressure

z

head at the bottom of the sample. In both data plots,

water re-entry is at first quite slow, rises quickly for the

next week or so, and then returns to a slower rate.

Although it is possible that melt-induced structural

changes caused this flow variation, bath temperatures

were fairly steady over both time periods. Because the

data plots are smooth and consistent, we attempt to

h0

model the water flow and thereby gain insight into the

ice permeability. Figure 11 shows computed flow rates

Air

Rc

for the porous plate alone and for hypothetical configu-

rations of the ice sample.

Ice Core

Figure 12 shows the simplified structure we assume

hi

Air

for the analysis: a cylindrical stackup of the porous plate

Gap

and a slightly narrower ice core, subject to a pressure

Water Front

z

Plate

head at the bottom of the porous plate. The initial gravi-

hp

tational head is a height h0 of water in the pipette. The

receding water level z′ in the pipette relates to the ris-

Water/Ice

tg

ing level z in the sample as z′ = φAr z, where Ar is the

ratio of the sample area to the pipette area and φ is the

ice porosity ahead of the water front. We assume a one-

dimensional treatment, but note that this is valid only

Water

in the absence of a radial pressure gradient beneath the

plate. A uniform pressure head is possible if the resis-

Figure 12. Idealized ice configuration used in flow

tance-wire heater (Fig. 1) kept the area beneath the plate

computations. Not to scale.

from totally freezing. If this area were instead blocked

by ice, we estimate that the radial gradient would slow

the upward velocity of the water front by roughly one-

seventh (e.g., Muskat 1937).

We model the water flow with Darcy's law:

11

Previous Page

Previous Page