cedures described in ASTM D5084. The large-

were separated using a sheet of PVC geomem-

brane that did not extend to the outer edge of the

diameter flexible-wall permeameter was used to

GCL (Fig. 3). The PVC captured water seeping

test specimens having a diameter of 12 in. (30 cm).

through the GCL, but allowed water leaking

Procedures in ASTM D5094 were used for tests in

through the edge seal to bypass the collection sys-

the larger-scale flexible-wall cell. Detailed descrip-

tem and flow out through a different drain. The

tions of the equipment and test methods are pro-

pea gravel beneath the PVC geomembrane was

vided by Chamberlain et al. (1990).

sloped to a drain pipe where the water was col-

We did 12 laboratory freezethaw tests in the

lected.

CRREL rigid-wall freezethaw permeameter

Hydraulic conductivity was measured through

(three each on the three soils, and one each on the

December 1993 until the water in the test pans

GCLs). Specimens were prepared in the laboratory

began to freeze. Measurements were restarted in

from samples taken from the site during construc-

April 1994. On 3 June 1994, several of the test pans

tion. The clays were compacted in the laboratory

emitted a strong septic odor, indicating some

to match field conditions, and placed in the CRREL

amount of biological growth. About 1 L of chlor-

freezethaw permeameter for testing. The confin-

ing pressure was maintained at 1 lb/in.2 (6.9 kPa),

ine bleach was added to each test pan in an

attempt to reduce the biological growth and pre-

and the hydraulic gradient was maintained

vent clogging of the system. After the chlorine was

between 2 and 5 during freezethaw testing. The

added, it appeared that the closed collection sys-

GCLs were tested in a similar manner.

tem may have been limiting the amount of water

Each specimen was subjected to 15 freezethaw

that could seep through the GCLs. After identify-

cycles, with hydraulic conductivity being mea-

ing the potential problem, a change was made that

sured after the first, third, fifth, tenth, and fifteenth

allowed seepage to be collected in a way that

cycle. Following these freezethaw cycles, the

ensured free drainage.

Parkview and Valley Trail clays were tested after

confining pressures were increased incrementally

Electronic instrumentation

to see how this affected hydraulic conductivity.

Forty temperature sensors and an automated

weather station were installed to permit moni-

Laboratory tests on field specimens

toring of freezethaw cycles, frost depths, and

of compacted clay

related climatic conditions. The data were col-

Hydraulic conductivity tests were also per-

lected every 5 minutes using a datalogger. Average

formed on large- and small-diameter unfrozen

hourly values were saved and transferred to a com-

soil specimens. Specimens were removed from the

puter at the CRREL laboratory in New Hampshire

field test pads before, during, and after the winter

via computer modem and cellular phone link.

seasons of 199293 and 199394. Large-diameter

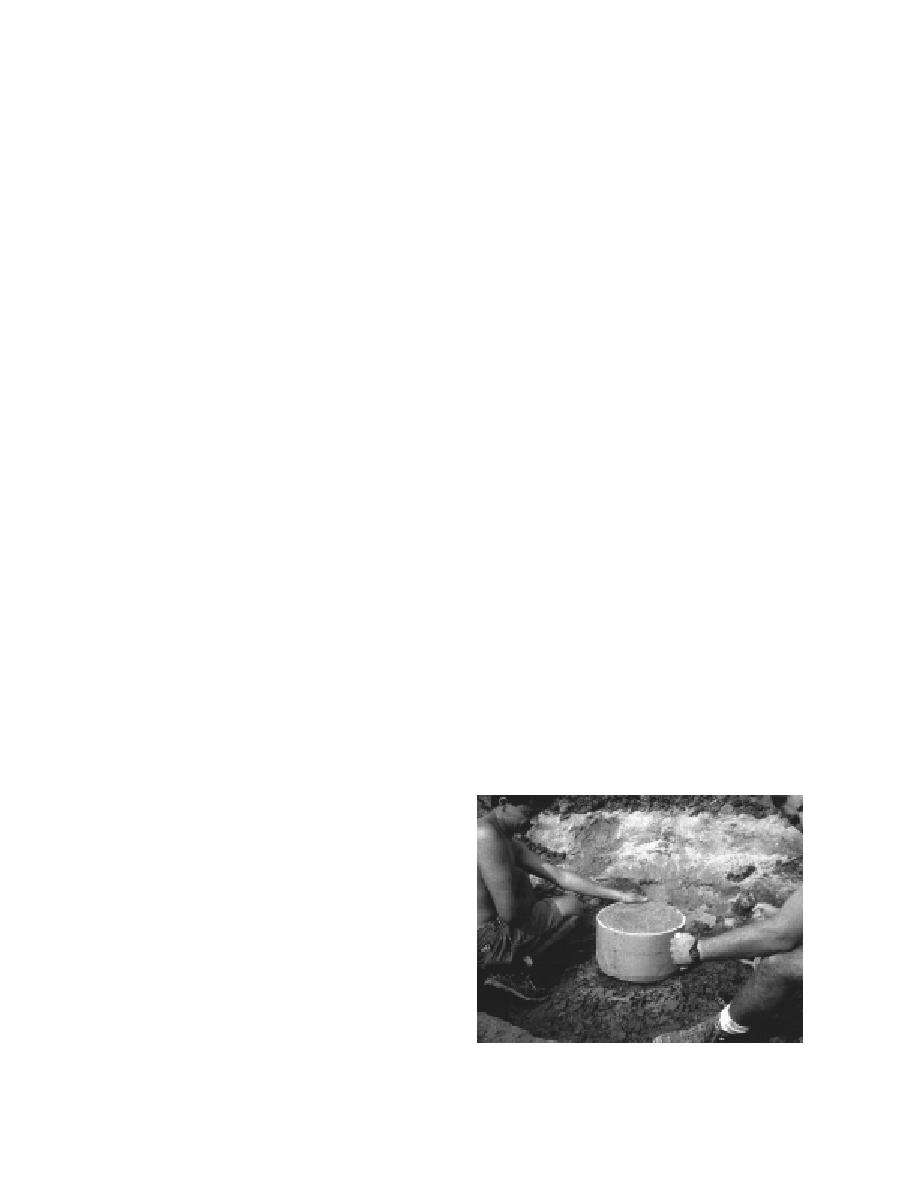

specimens (Fig. 4) of thawed clay and sand

bentonite were removed from the test pads by

Laboratory hydraulic conductivity

hand carving 12-in.- (30-cm-) diameter soil blocks

testing program

Hydraulic conductivity tests were performed

in the laboratory for comparison to measurements

made using the field permeameters. Three types

of permeameters were used in the laboratory test-

ing: 1) the rigid-wall CRREL freezethaw perme-

ameter (CRREL), 2) the conventional flexible-wall

permeameter (CRREL and UW-Madison), and 3) a

large-diameter flexible-wall permeameter (UW-

Madison).

The CRREL rigid-wall freezethaw permeame-

ter allows specimens to be frozen and thawed and

tested for hydraulic conductivity. The freeze

thaw cycle can be repeated many times, freezing

rates are controlled, and the freeze front moves

vertically. The conventional flexible-wall per-

meameter tests were conducted on unfrozen spec-

Figure 4. Taking a 12-in.- (30-cm-) diameter hydraulic

imens (diameter of 2.75 in. [7 cm]) following pro-

conductivity test specimen from the field.

7

Previous Page

Previous Page