10-3

Test results from specimens that were

taken from a region more than 1 ft (0.3 m)

Parkview Clay

below the maximum frost depth in test

10-4

pads PV-3 and VT-4 did not show any

15

increases in hydraulic conductivity.

Shrinkage cracks and ice lens cracks were

Field Frozen

10-5

4

not obviously present in the soil that was

well below the reach of the frost zone and,

Lab Frozen

therefore, an increase in hydraulic conduc-

10-6

1

tivity would not be expected. However, in

the zone within 6 in. (15 cm) of the freezing

front, the hydraulic conductivity was

-7

10

about 1 106 cm/s in the Valley Trail test

0 Freeze-thaw Cycles

section (Fig. 8). Thus, it appears that freez-

10-8

ing affects the hydraulic conductivity some

0

2

4

6

8

10

12

small distance below the freezing front.

Effective Stress (psi)

This is consistent with the prevailing ice-

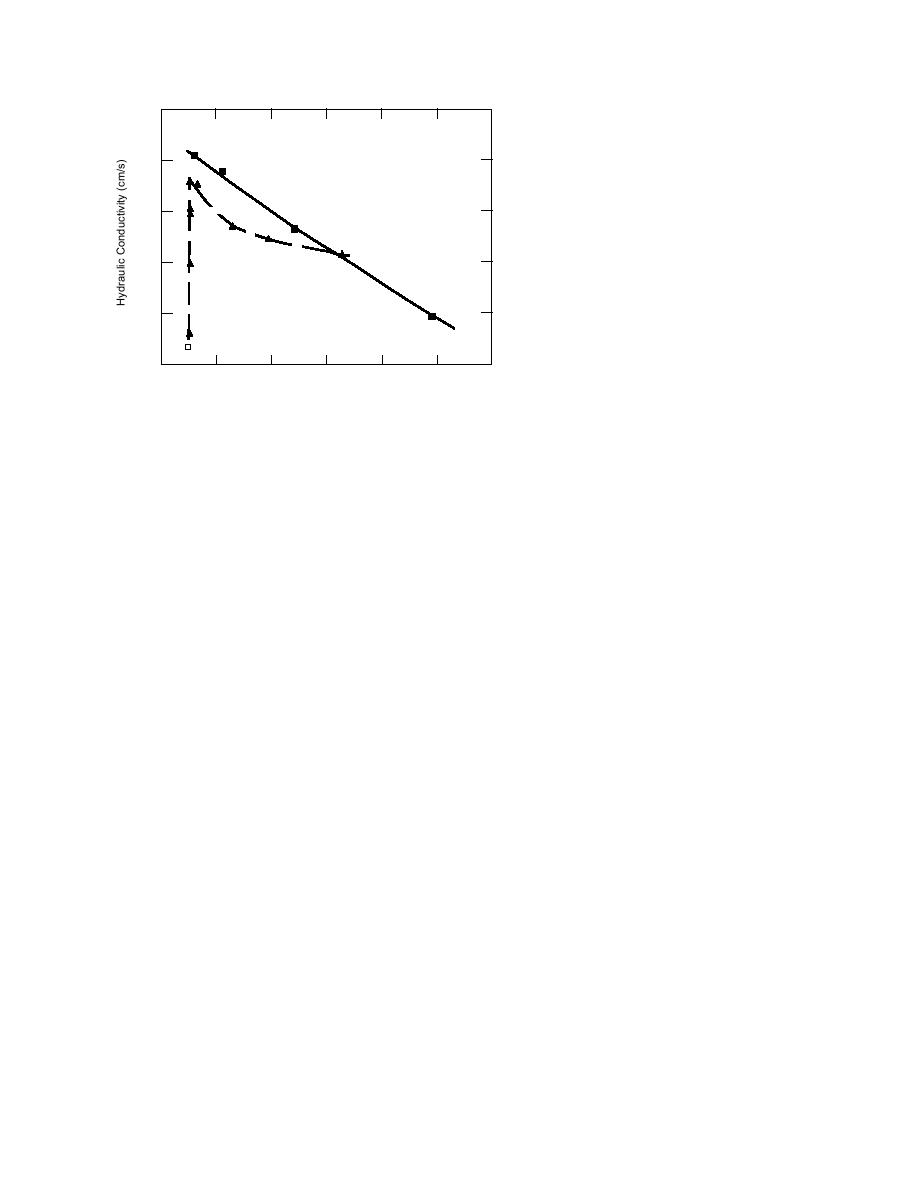

Figure 13. Impact of effective stress on the hydraulic conductivi- segregation theory that the shrinkage

cracks are formed in the unfrozen soil

ty of Parkview clay after freezing and thawing.

beneath the freezing front because of the

whereas in a liner, there can easily be sufficient

high moisture suction that develops there.

overburden stress to close the cracks and reduce

The effects of stress on crack closure led us to

the hydraulic conductivity to an acceptable value.

examine whether the damage to the clay material

About 25 ft (7.6 m) of overlying soil and waste

caused by freezing could be repaired in place

material would be required to close the cracks in a

without its being removed. Three passes of a

liner constructed with the Parkview and Valley

rubber-tired scraper were made over the test pads

Trail soils. This is an overburden readily achieved

to increase the stress level. Observations of the

in most landfills, except at the margins.

clay structure in the test pads made after the clay

The test specimens taken with the thin-wall

was remolded with the scraper showed that this

sampling tubes after freezing and thawing had

apparently destroyed the blocky structure by

lower hydraulic conductivities than the block and

compressing the shrinkage and ice lens cracks.

core specimens. The hydraulic conductivities for

Blocks caused by shrinkage cracks and ice lenses

these specimens were similar to the values exist-

were not as visible.

ing before freezing (Table 2). One explanation for

Large-diameter blocks were carved from these

this difference is that a tube sampler disturbs the

samples in July 1994. Tests on large blocks

unique soil structure formed during freezing, the

removed from the remolded area showed that the

cutting and inside wall resistance that develops

hydraulic conductivity values obtained before

as the tube is pushed into the ground causing the

freezing were nearly recovered.

increase in the stress on the sample. As was dis-

cussed in the previous paragraph, about 12

Sandbentonite

2 of stress is needed to close the cracks in the

lb/in.

In contrast to the natural clay, comparisons of

clay soils examined in this project. For the tube

our laboratory and field tests on the sand

samples taken from the Parkview and Valley Trail

bentonite mixture showed no effect on hydraulic

test pads, considerable stress was applied to

conductivity from freezethaw. The test results

cause the sampler to penetrate the compacted

are shown in Table 2. The hydraulic conductivity

clay. Apparently, this stress is sufficient to close

measured in field test-pad permeameter SB-1 was

less than 5 108 cm/s in June and July 1994 after

the cracks and reduce the hydraulic conductivity

to the values existing before freezing. This was

two winter seasons. This is roughly the same as

confirmed, as visual inspection of the samples

was measured in the CRREL laboratory tests (be-

removed from thin-wall sampling tubes did not

fore and after freezing) on specimens prepared in

reveal any of the usual blocky structure observed

the laboratory from sandbentonite samples

in the hand-carved large-diameter samples.

mixed in the field.

These results and the effect of sampling technique

The sandbentonite in test pad SB-1 showed

are discussed further by Benson et al. (1994).

none of the blocky structure that was present in

12

Previous Page

Previous Page