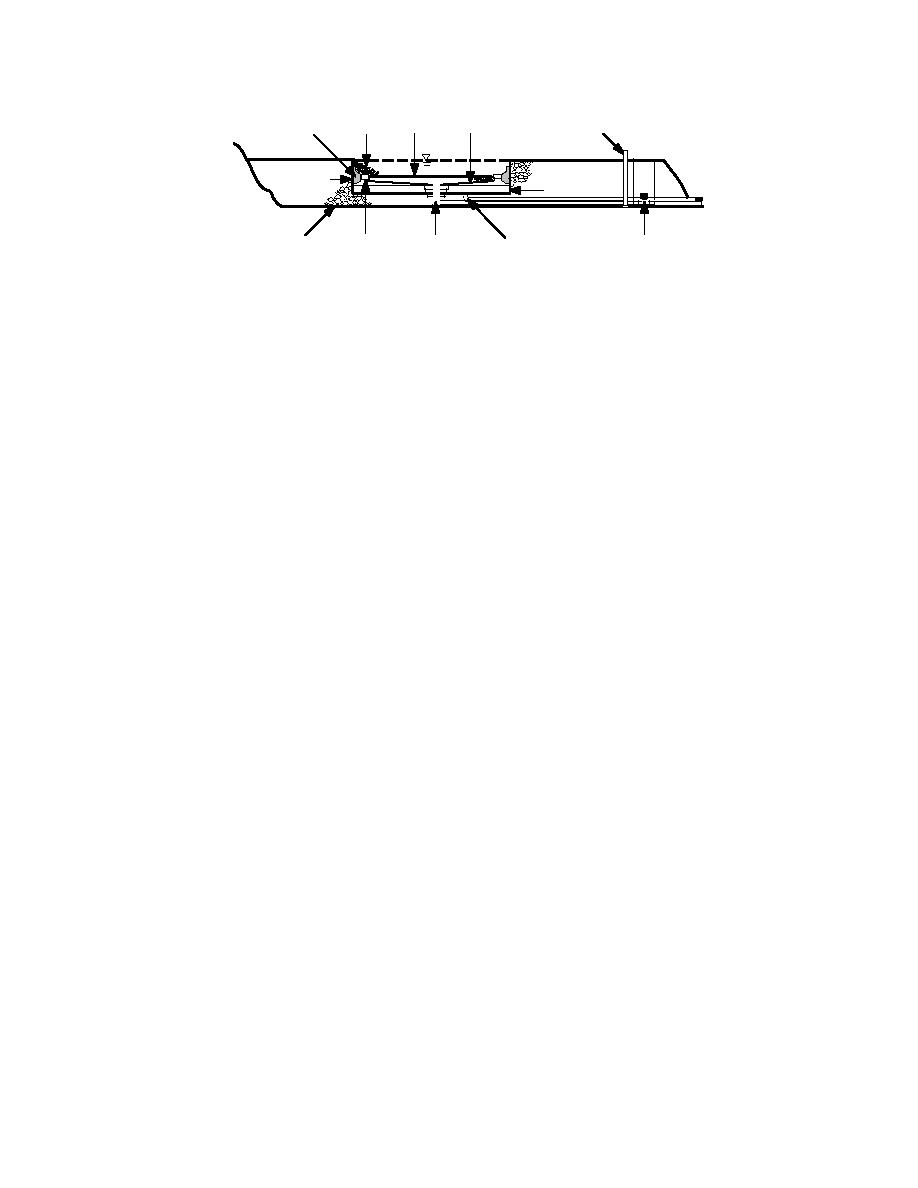

PVC

1 cm

20 mil PVC

Pea Gravel GCL

Cover Strip

Vent Pipe

Membrane

Bentonite

0.6 cm

Edge

HDPE Tank

Seal (paste)

Seepage

Side Leakage

4 cm

Bentonite

PVC Seepage

Drain

Drain

Minus Stone

Paste

Collection Control

Valve

Figure 3. Details of the GCL test pans.

underlying HDPE. Piping and filter material were

Nine test pans (Fig. 1) were constructed in three

installed that connected to the geonet drain

groups (one group for each GCL). Each group con-

(placed below clay before compaction), thus

tained two sizes of test pans. Two test pans in a

group had a surface area of about 8 ft2 (0.75 m2).

allowing water that seeps through the block of

clay to flow to a sump for observation and possi-

The third test pan in each group had a surface area

of 20 ft2 (1.9 m2). The large test pan and one of the

ble measurement. The 4-in. (10-cm) space be-

tween the block of clay and the inside wall of the

small test pans in each group were used to test a

HDPE box was filled with bentonite grout to pre-

GCL with a seam in the long dimension. The seams

vent side leakage. A layer of nonwoven geotextile

were made in accordance with the manufacturer's

was placed on top of the clay and covered with a

specifications. The other small test pan in each

layer of coarse, 2-in. (5-cm) or smaller washed

group contained a GCL with no seam.

gravel that filled the space between the top of clay

The smaller test pans were commercially avail-

and the top of the HDPE box. An HDPE lid was

able HDPE storage pans. The larger ones were

placed and seamed on top of the box. A 1-in.- (2.5-

made by welding together pieces of HDPE plate

cm-) diameter PVC riser pipe was placed at the

stock (Fig. 3). A seepage collection system with

high point of the lid to allow water to be added to

drains was designed and constructed in each test

the system and inflow of seepage to be measured.

pan and then covered with a GCL. Bentonite caulk

During testing, the permeameters were cov-

and strips of plastic were used to prevent leakage

ered with about 2 ft (0.6 m) of sand or gravel. This

along the sides of the GCL, which was then cov-

material was placed to hold the flexible HDPE lid

ered with about 10 in. (25 cm) of pea gravel to the

in place so that uplift of the lid was prevented.

top of the test pans.

Seepage was measured by filling the riser pipe

The area surrounding the test pans was filled

until the water level stabilized, and then regularly

with gravel to the same level as that in the pans,

monitoring water levels. In winter, the sand cover

so that freezing and thawing would be one-

was reduced to 4 in. (10 cm) so that the cover over

dimensional.

the permeameter was the same as that over the

Water was initially added to the test pans to a

rest of the test pad.

depth of 1 in. (2.5 cm) over the GCLs to allow the

bentonite to hydrate under low head conditions.

GCL test-pans

After 1 week at the low head condition, more wa-

Our goal during the GCL portion of the field

ter was added. The test pans were allowed to hy-

investigations was to compare and investigate

drate under this condition for 1 month before we

began collecting seepage data. The water level was

and after winter. Three 32- 13-ft (10- 4-m)

kept relatively constant during the tests. Hydraulic

ponds, each lined with a different GCL under 10

gradients used in the field test pans ranged from 5

in. (25 cm) of cover, were constructed during the

to 15 and averaged 10. The test pans were not

fall of 1992 (Fig. 1). The ponds had underdrains

drained for winter; they remained full of water.

beneath them. The goal was to measure the

Water from a surface water pond located adjacent

hydraulic conductivity after freezing and thaw-

to the landfill was used as the permeant.

ing. However, a flaw in the seepage measurement

The seepage through the GCL and the seepage

system prevented it from working as planned.

past the edge of the GCL were separated by the

The problem could not be corrected, so a different

collection system. This was done so that water

test system was designed and constructed in Sep-

from a leaking edge seal would not be mistakenly

tember 1993.

included with seepage through the GCL. The flows

6

Previous Page

Previous Page