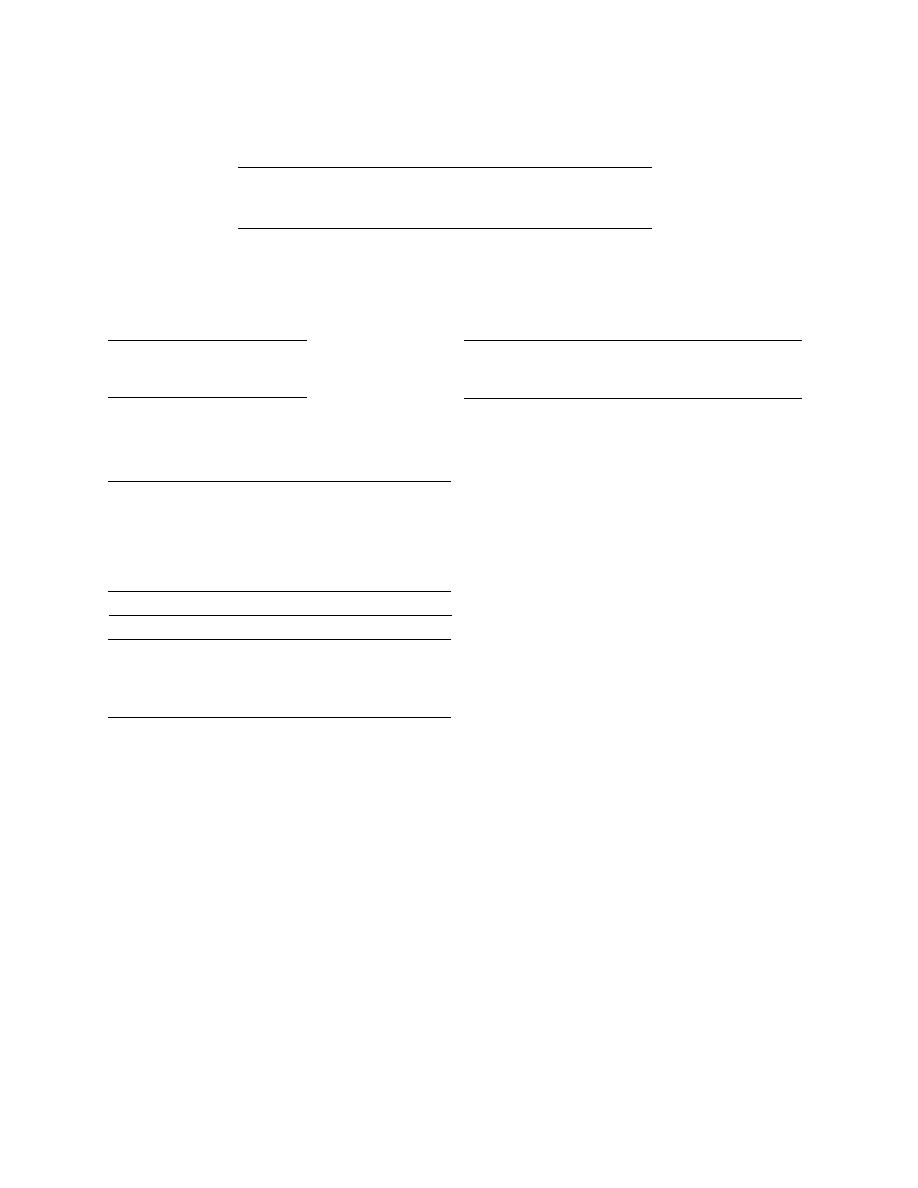

Table 17. Mixture proportions per cubic meter, Michigan.

Coarse

Portland

Admixture dosage

aggregate

cement

(wgt active ingredient

(19-mm)

Sand

Type IA

w/c

per cement wgt)

Mixture

(kg)

(kg)

(kg)

ratio

(%)

Control

1045

772

391

0.41

0

PolarSet

1045

772

391

0.43

5.2

DP

1045

772

391

0.41

5.2

Table 19. Properties of fresh concrete, Michigan.

Table 18. Concrete placement

time, Michigan.

Air

Unit

Concrete

Slump

content

weight

temperature

(C)

(kg/m3)

Mixture

(cm)

(%)

Mixture

Date

Start

Control

5

3.2

2309

12

Control

15 Mar

11:00 am

PolarSet

11

5.3

2293

8

PolarSet

17 Mar

10:50 am

DP

13

8

2164

7

DP

17 Mar

1:10 pm

for warm environments. Antifreeze admixtures

Table 20. Winter cost estimate.

open new possibilities and the challenge to adapt

Shelter

standards accordingly.

Erect shelter

Antifreeze admixtures offer potential use in

(6 men, 1/2 day @ /hr)

2.00

various applications. In building construction,

Heat shelter: 1 day prior to pour and 7 days after

floor slabs and wall sections can be placed with-

(8 days @ 81 L propane/day @

||content||

.206/L3.54

out the need for temporary shelter. However,

Dismantle shelter

6.00

Materials: Assume 9 reuses (Total cost

whether or not the method of antifreeze admix-

estimated at 62)

118.00

tures may be advantageous over conventional

thermal protection depends on the specific job

Total estimated cost of shelter

79.54

circumstances. For some jobs, building a construc-

Antifreeze admixture

tion shelter may be useful for worker comfort, at

5.12 m3

Volume of concrete placed inside shelter

least during work periods.

98 cm3

Dosage of admixture per kg of cement

Because of the ability to place concrete in the

Amount of cement per m3 of concrete

391 kg

Amount of admixture per 5.12 m3 of concrete

196 L

cold and let the concrete be cold while developing

Cost of admixture to equal cost of shelter

.51/L

acceptable strengths, antifreeze mortar and con-

crete can be safely placed on cold substrates. This

option allows for applications such as joints in

precast concrete structures, repair of dams, tun-

70. Heating accounted for nearly 15 percent of

nels, foundations, etc., where a massive structure

this expense. Because antifreeze admixtures are

is cold.

still prototypes, their market price has not been

Winter paving operations can benefit greatly.

determined. However, based on the estimate de-

With antifreeze admixtures, the concrete does not

veloped for the shelter in this project (Table 20),

need to be thermally protected, and it can be placed

the break-even cost of the antifreeze admixtures

directly on cold granular bases. From the stand-

would be .51 per liter.

point of worker comfort, the highly mechanized

operation of paving makes this type of work pos-

sible at even lower temperatures than for vertical

POTENTIAL APPLICATIONS OF

building construction. Thus, there is ongoing need

ANTIFREEZE ADMIXTURES

to search for admixtures that work at very low

temperatures.

The current standards were written under the

In general, summer construction is less expen-

assumption that concrete cannot develop strength

at acceptable rates when the temperature is lower

sive, but there are applications where the job must

than 5C. Current testing methods are designed

be done in the winter and against cold substrates.

18

Previous Page

Previous Page