antifreeze admixture code-named DP, which was

crete was exposed to ambient air and was in di-

developed in this project. A third slab contained

rect contact with the cold gravel base course, which

the admixture PolarSet (PS), a low-temperature

was placed directly on frozen ground. No insula-

accelerator newly marketed by WRG. The ad-

tion, shelter, or heater was used on the admixtured

mixtured slabs were cast and cured in the open

slabs. The plastic sheet was placed over the two

without shelter. The prototype application in New

exposed concrete sections for seven days to mini-

Hampshire provided some experience in deal-

mize water loss because no curing water was

ing with these admixtures in cold weather. The

added. The concrete in the heated shelter was left

slabs at the Soo Locks provided an opportunity to

uncovered for the seven-day curing period.

apply the new admixtures in a realistic cold

weather setting with conventional equipment and

Observations and results

conventionally trained labor.

Each reinforced slab on grade measured 5.5 m

Workability

wide by 6.1 m long by 15.2 cm thick. The slabs

The concrete stayed workable longer than it

were cast 1517 March 1994. The Corps' Soo Area

did in the prototype application in New Hamp-

shire. The mixtures were 36C colder in Michigan.

Office had scheduled 39 sections of concrete to be

replaced because of their advanced stage of freeze

thaw deterioration. The work area was located on

Finishability

the southwest pier, which borders the ship canal

The concrete workers indicated that the two

of the Soo Lock, the largest of four locks operated

mixes, DP and PolarSet, finished quite easily. The

and maintained by the Corps of Engineers, Sault

DP did seem to stiffen right at the end of the

Sainte Marie, Michigan. Inspection and repair of

finishing operation, about two hours after water

the locks themselves is normally done during the

was first added to the mix. However, the concrete

winter months, January through March, when

that was left over in a wheelbarrow from the

shipping is stopped. Other repair work, such as

sample-making procedure was still workable. The

the replacement of the slabs described here, is

DP contained a different water reducer than that

also most conveniently done during the winter

used in New Hampshire; WRDA-19 was used in

nonshipping season, making this test particularly

New Hampshire, while AA1D was used in Michi-

relevant.

gan. The first is a commercial product of WRG

The temporary heated enclosure erected over

while the second was still in research there.

the control slab provided a comparison between

conventional and antifreeze concrete operations.

Thermal records

The two admixtured slabs were placed on a cold

Four thermocouples were equally positioned

gravel bed. After consolidation and finishing op-

through the thickness of the PolarSet and DP slabs

erations were conducted conventionally, the fresh

at about 2.5 m from the edge. One thermocouple

slabs were covered with a plastic sheet. The con-

monitored air temperatures.

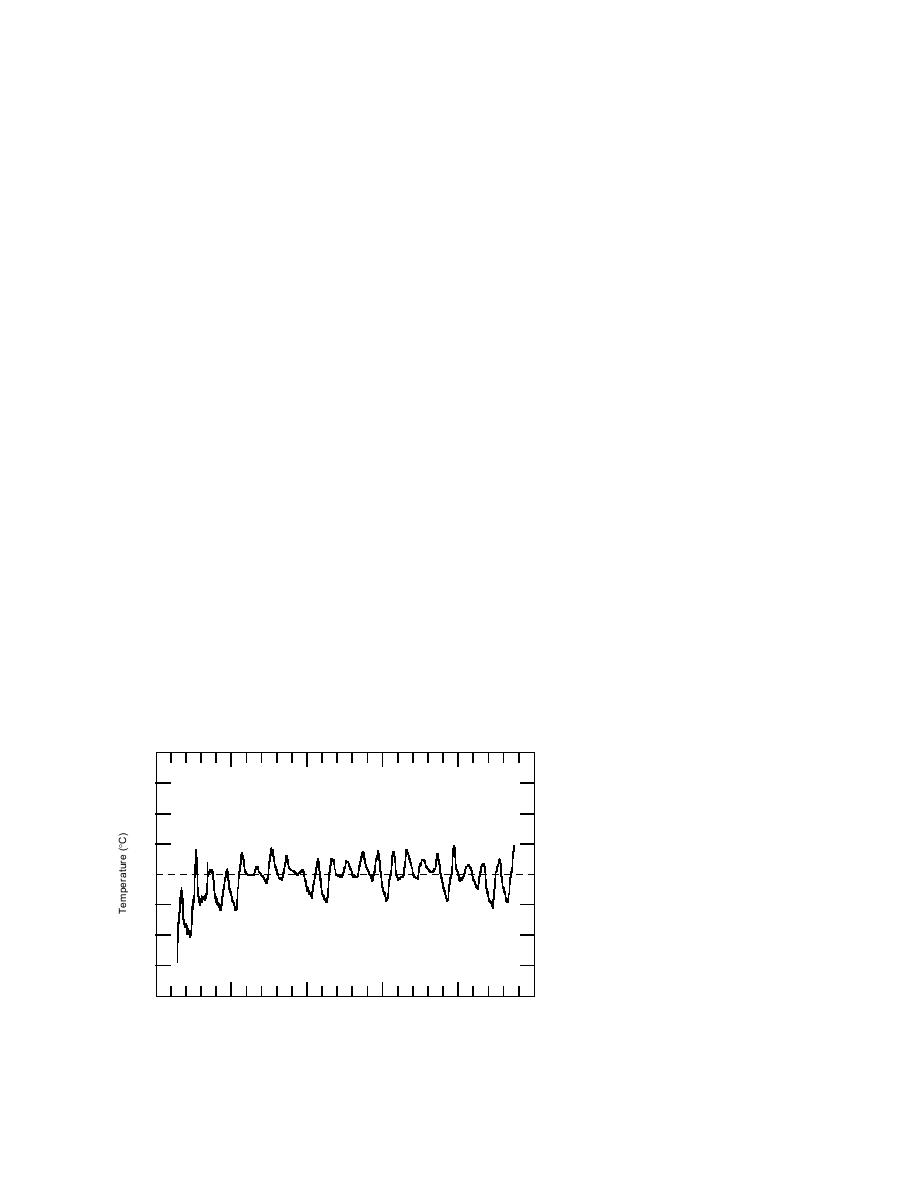

Figure 5 shows a 22-day record of

air temperature beginning at 9:50 a.m.,

20

16 March. The air temperatures from

15

1617 March were quite cold, averag-

ing 10C, with a low of 16.5C at

10

6:45 a.m. on the 17th. Steady winds

created wind chills of 28C. The air

5

temperature averaged only 0.5C for

0

the next seven days. The overall aver-

age air temperature for the first nine

5

days was 1.6C.

The control concrete was cast on

10

15 March. This slab was cast in a shel-

ter that was heated for the first seven

15

days; the heater was then turned off,

20

but the shelter stayed in place for

0

5

10

15

20

25

about a month. Nineteen days of tem-

Days

perature records from four positions

Figure 5. Air temperatures at the construction site.

15

Previous Page

Previous Page