20

1.27 cm Below Top Surface

15

2.54 cm Above Slab Bottom

1.9 cm Below Slab

10

5

Middle of Slab

0

5

10

0

5

10

15

20

25

Days

Figure 8. Concrete temperatures for the slab containing admixture DP.

stored unprotected next to the slabs. Air-void

control concrete cured under the heated condi-

tion. The mixture proportions are given in Table

parameters were not determined.

17, placement time of the concrete in Table 18, and

the properties of fresh concrete in Table 19.

Strength development

Concrete cylinders were cast during construc-

Cost comparison between

tion. For the heated control slab, the cylinders

were stored for curing on the ground near the

conventional and antifreeze concrete

slab and on an overhead shelf. For the admixtured

As previously mentioned, a heated shelter was

used for the control concrete. This provided an

concrete slabs, the cylinders were stored for cur-

opportunity to compare costs between normal

ing partially embedded in cold gravel at the edge

winter concreting to those using antifreeze ad-

of the concrete slabs. Also, a second set of cylin-

mixtures. Based on these field tests, it is apparent

ders for each admixtured concrete was stored on

that the main difference between normal concrete

an overhead shelf in the heated enclosure. The

and antifreeze concrete is the heat, shelter, and

cylinders were 7.5 cm in diameter by 15 cm in

labor needed to protect normal concrete compared

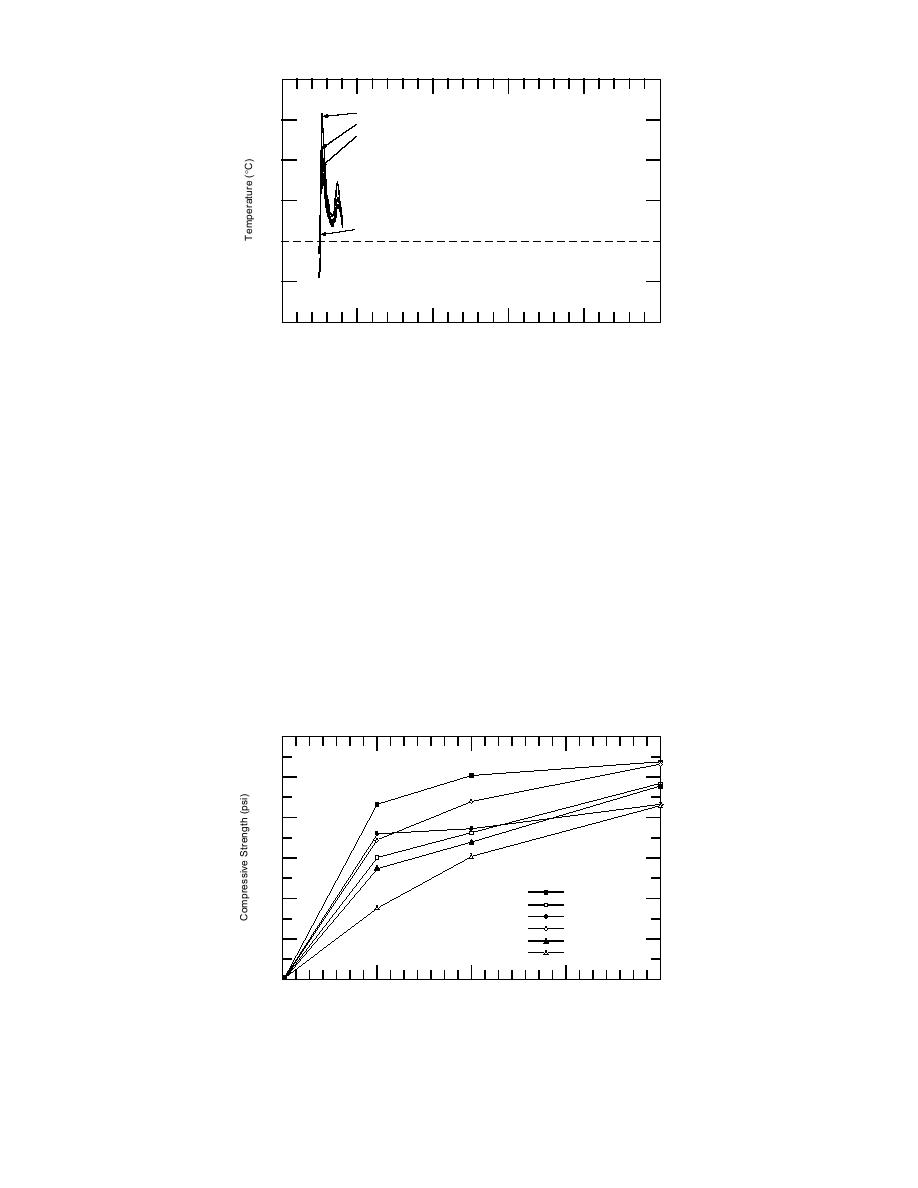

length. Figure 9 shows their compressive strengths

to the chemicals needed to protect antifreeze con-

at various ages. The strengths of the concrete cyl-

crete. The cost to erect, heat, and dismantle the

inders containing the admixtures, stored heated

temporary shelter at Soo was estimated to be

and unheated, exceeded the strength of 28-day

6000

5000

4000

3000

Control

Control (est)

2000

(est)r o Site

Conttroll Site

Con

ConttrolCeiling

Conrol Ceiling

PS Site

PS Site

1000

DP Site

DP Site

Conttrol+5C

Conrol +5 C

0

28

21

0

7

14

Concrete Age (days)

Figure 9. Compressive strength of cylinders (some cured in the heated

shelter and some next to open slabs).

17

Previous Page

Previous Page