Table 15. Mixture proportions per cubic meter, New Hampshire.

Coarse aggregate

Sand

Air-

Water

Admixture dosage

(19-mm crushed

(natural,

Portland

entraining

reducer

(wgt active

ledge, 0.5%

1.1% abs.

cement

admixture

(WRDA

ingredient per

2.89 SG)

2.71 SG)

Type II

w/c

(Daravair)

w/Hycol)

cement wgt)

(cm3)

(cm3)

Mixture

(kg)

(kg)

(kg)

ratio

(%)

PS

1010

787

422

0.44

133

798

6

DP

1015

784

416

0.43

266

798

6

DPTC

1021

784

422

0.42

237

828

6

derived from previous laboratory data. As can be

Table 16. Properties of fresh concrete, New

Hampshire.

seen, all field samples performed well. They ex-

ceeded minimum strength requirements. In addi-

Air

Unit

Concrete

tion, the concrete was estimated to have attained

Slump

content

weight

temperature

at least 12 MPa before it reached 5C. The con-

(C)

(kg/m3)

Mixture

(cm)

(%)

crete was able to resist freezing at that strength,

PolarSet

8

3

2293

10

shown by the fact that no ice damage was de-

DP

11

7.2

2293

13

tected in core samples removed from the bin in

DPTC

5

6.4

2341

13

May.

tion between the cement and water

8000

had been completed by then.

The slab reached a mostly uniform

temperature within 18 hours. The

6000

wall achieved uniform temperature

almost immediately. The wall, hav-

ing two surfaces exposed to the am-

4000

bient air, was most easily affected

PS-Room

by surrounding air.

PS-Field

DP-Room

Strength development

DP-Field

2000

DPTC-Room

The concrete was transported by

DPTC-Field

Control +20C

rotary-drum truck from a ready-mix

Control +5C

plant 16 kilometers from CRREL. The

0

concrete was mixed using unheated

21

28

0

7

14

aggregate with heated water (82C).

Concrete Age (days)

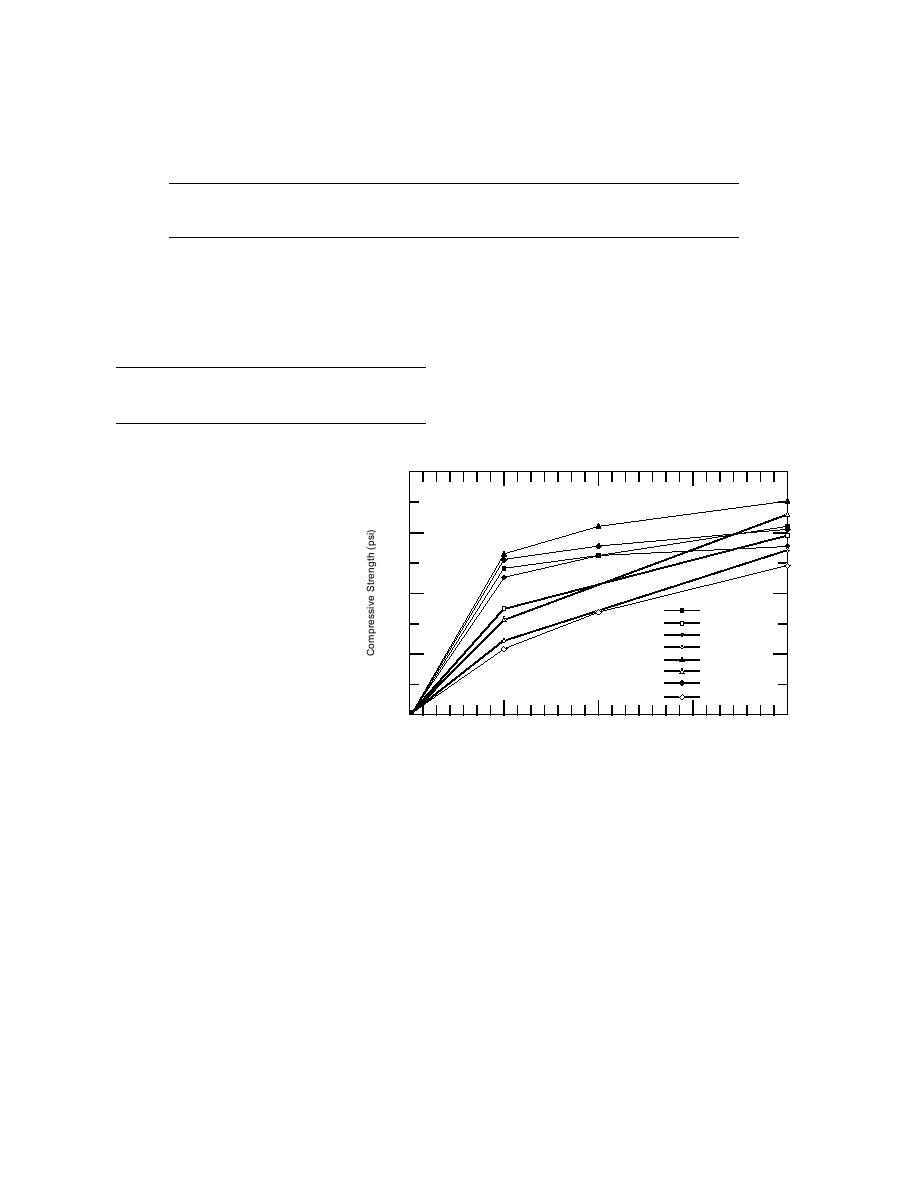

The ingredients were added into the Figure 4. Compressive strength of pullout cylinders from wall-slab

truck's drum, mixed a few minutes, prototype.

and then transported 1520 minutes

to the construction site. The mix proportions are

FIELD APPLICATION OF

given in Table 15. The truck took about 15 min-

DEVELOPED ADMIXTURES

utes to discharge its load, and finishing opera-

tions took another 30 minutes. Table 16 gives prop-

Soo Locks slabs

erties of each mixture as delivered to the site.

Results of the strength tests from the field-cured

Objective

pullout cylinders taken out of each concrete sec-

To demonstrate the practicality of using anti-

tion are presented in Figure 4. The target slump

freeze admixtures under field conditions.

was 10 cm.

Control, admixture-free concrete was not mixed

Description

during this experiment. The control curves in-

Three on-grade slabs were cast. One slab was

cluded in Figure 4 correspond to concrete of simi-

made of admixture-free concrete to act as a con-

lar mix proportions made with aggregates and

trol. It was protected with a heated shelter. A sec-

cement from the same sources. These values were

ond slab was made with concrete containing the

14

Previous Page

Previous Page