The poor agreement of the tolerance intervals with

nested experimental design could be used to de-

the editing limits implies that the standard devia-

termine the magnitude of these errors prior to

tion of the log ratios was larger than expected for

instituting corrective measures.

a good-fitting lognormal distribution. A look at

The GC-FID method may be a significant

the histogram (Fig. 8) shows that there are more

source of error for TPH determinations. Besides

ratios than expected toward the extremes and

inevitable random errors, the unique arrangement

fewer than expected in the center. Deficiency of

followed by the Corps of Engineers may allow

ratios near the ideal value of 1.00 (log = 0) may

systematic errors such as calibration or signal in-

be due to systematic bias as suggested in later

tegration biases to appear as random error. We

paragraphs.

refer to the use of a given laboratory for the QA

As with the VOCs, we found no meaningful

function on one project and for the QC function

correlation between either surrogate recoveries or

on another project. Thus, if a laboratory reports

MS/MSD results with corresponding QC/QA ra-

consistently low results, they would inflate QC/

tios. In many cases MS/MSD results were absent

QA ratios when serving as a QA laboratory but

or were indicated to be unavailable because they

they would depress ratios when acting as a QC

were diluted out of range. In other examples ex-

laboratory.

hibiting very poor agreement between QC and

We believe that GC-FID for TPH is susceptible

QA results, surrogate recoveries were excellent

to systematic error, especially in the integration

and MS/MSD results were quite good. We must

of peaks on chromatograms with broad undiffer-

ask whether MS/MSD results are providing

entiated background. This is particularly true for

enough useful information to justify the cost. Per-

weathered residues where the normal hydrocar-

haps the use of independently prepared second-

bons, which produce a very recognizable pattern

ary standards would offer greater cost/benefit.

in fuels, have been reduced relative to the

More will be said on this later.

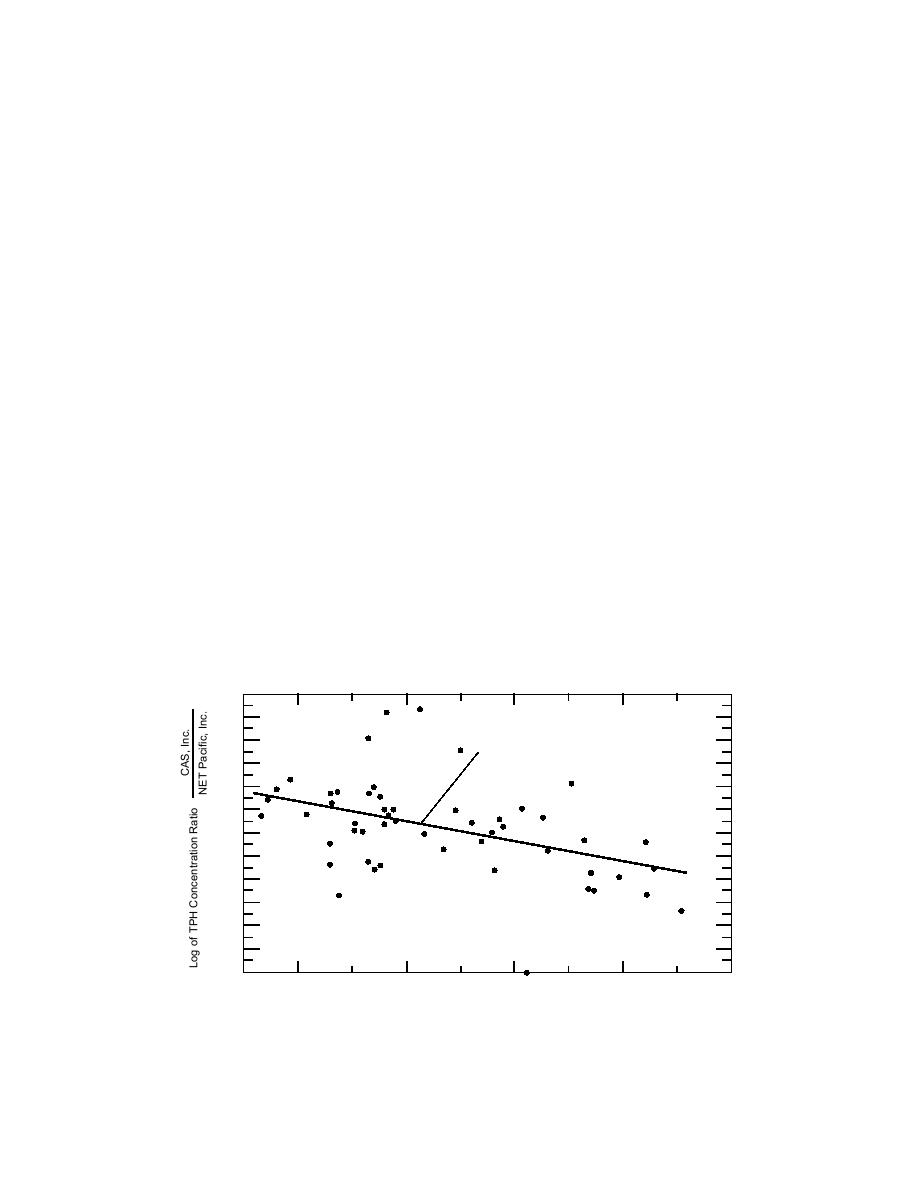

branched chain components. Evidence of bias is

Some of the random error undoubtedly arises

found in Figure 12. NET Pacific, Inc., Santa Rosa,

as a consequence of sampling and splitting soils

California, was the QA or the QC laboratory for

with heterogeneously distributed petroleum hy-

all 95 QC/QA ratios computed from NPD results.

drocarbons. Possibly contractor guidance can be

In 52 cases the other laboratory was CAS, Inc.,

revised to reduce this source of error. Volatiliza-

Kelso, Washington. NET Pacific was the QA labo-

tion seems unlikely to be a major source of error,

ratory 28 times and the QC laboratory 24 times.

but that too could be examined. Biodegradation

When we plotted the log of the concentration ra-

is another potential source of error. A well-planned

tios for CAS, Inc./NET Pacific, Inc. vs. the log of

1.4

1.2

1.0

y = 0.629 0.170x

"r" = 0.439

0.8

0.6

0.4

0.2

0

0.2

0.4

0.6

0.8

1.0

1

2

3

4

5

Log of TPH Concentration (ppm) Reported by NET Pacific, Inc.

Figure 12. Correlation of soil TPH concentration ratios for CAS, Inc./NET Pacific, Inc.

with soil TPH concentration estimates reported by NET Pacific, Inc.

14

Previous Page

Previous Page