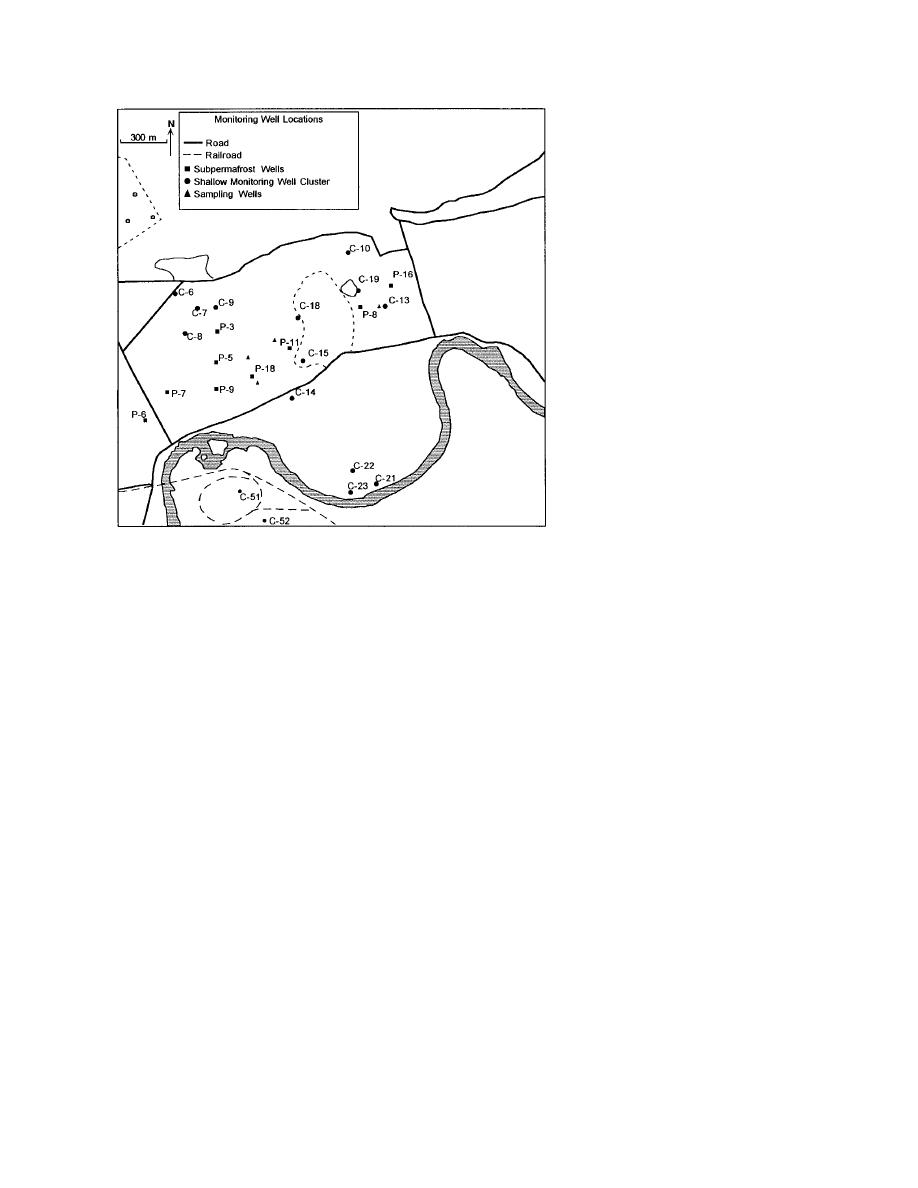

Figure 8. Monitoring wells in which

the CRREL ground water flow system

is installed.

screened interval of the monitoring wells. This

and affecting measurements. During installation,

material consisted of a commercially available

each hole was allowed to collapse around the

sand mixture (sieve no. 812), compacted to a

filter-covered screen as a way to minimize the

porosity similar to most materials in the well

well's effect on ground water movement. Moni-

screen intervals. A constant displacement pump

toring wells set in the subpermafrost aquifer were

was used to regulate seepage rates in the flume

screened at a depth beginning 3 m below the per-

from 1 to 10 ft/day (0.3 to 3 m/day). An empirical

mafrost. Water levels were recorded in sub-

linear relationship between sensor readings and

permafrost wells after they were completed.

seepage rates was determined for each system for

a known direction of flow. The accuracy of the

Ground water flow system

flow system is 0.1 ft/day (0.03 m/day) over the

CRREL's prototype ground water flow system

range of 0.5 to more than 10 ft/day (0.15 to more

uses the thermal tag and trace technique (e.g.,

than 3 m/day). Direction, as defined by ten mea-

Chapman and Robinson 1962, Hess 1982) to mea-

surements in the flume, is accurate to within 5.

sure flow direction and seepage velocity. The

Details of the calibration procedure are given in

system uses a sensor with four pairs of platinum

Williams et al. (in prep).

resistive temperature devices (RTDs) in steel tynes

Seepage direction and velocity are measured

arrayed in a circular pattern around a point source

four times per day in summer and twice per day

heater (Fig. 9a). Heat is transferred preferentially

in winter, with system functions controlled by a

by ground water flow from the heater to the RTDs.

Campbell CR10XT datalogger (Fig. 9b). Signals

Conductive heat transfer is enhanced by glass

are transmitted by cable from the flow sensor,

beads placed into the screen in which the RTD

which is held by steel rods and a clamp at a speci-

tynes are imbedded. Temperature fluctuations

fied depth. Power is provided by an external 12-

between paired RTDs, relative to background

V, deep cycle battery, charged by a solar panel

levels, are recorded. This temperature differential

mounted on a pole with the control unit (Fig.

is then used to calculate the direction of flow and

9c). A pressure transducer (Druck PDCR-35D)

seepage velocity.

installed in each well records water level (piezo-

Each sensor was calibrated individually in a

metric surface) fluctuations at the same time as

section of well screen set in a flume filled with

flow measurements. Data are stored using a

materials generally representative of those in the

8

Previous Page

Previous Page