.

σC = 295.22 ε 0.91 φ B0.5

r2 = 0.993

0.21 0.35

σC = 0.73 + 87.44ε φB

S D = 0.09

r 2 = 1.000

S D = 0.02

10

101

a

a

1

0

10

104

0.1

80

106

1

1)

10

60

10 4

te (s

φB , Bulk

40

n Ra

80

108

. , Strai

φ B , Bu

20

6

60

Porosity

ε

10

1)

40

(‰)

lk Por

s

(

n Rate

10 8

20

osity (

ε, Strai

‰

)

10

101

b

b

φ B = 20

φ B = 20‰

1

100

100

100

0.1

10 1 8

108

107

106

105

104

103

10 7

10 6

10 5

10 4

10 3

10

.

ε , Strain Rate (s 1)

ε, Strain Rate (s 1 )

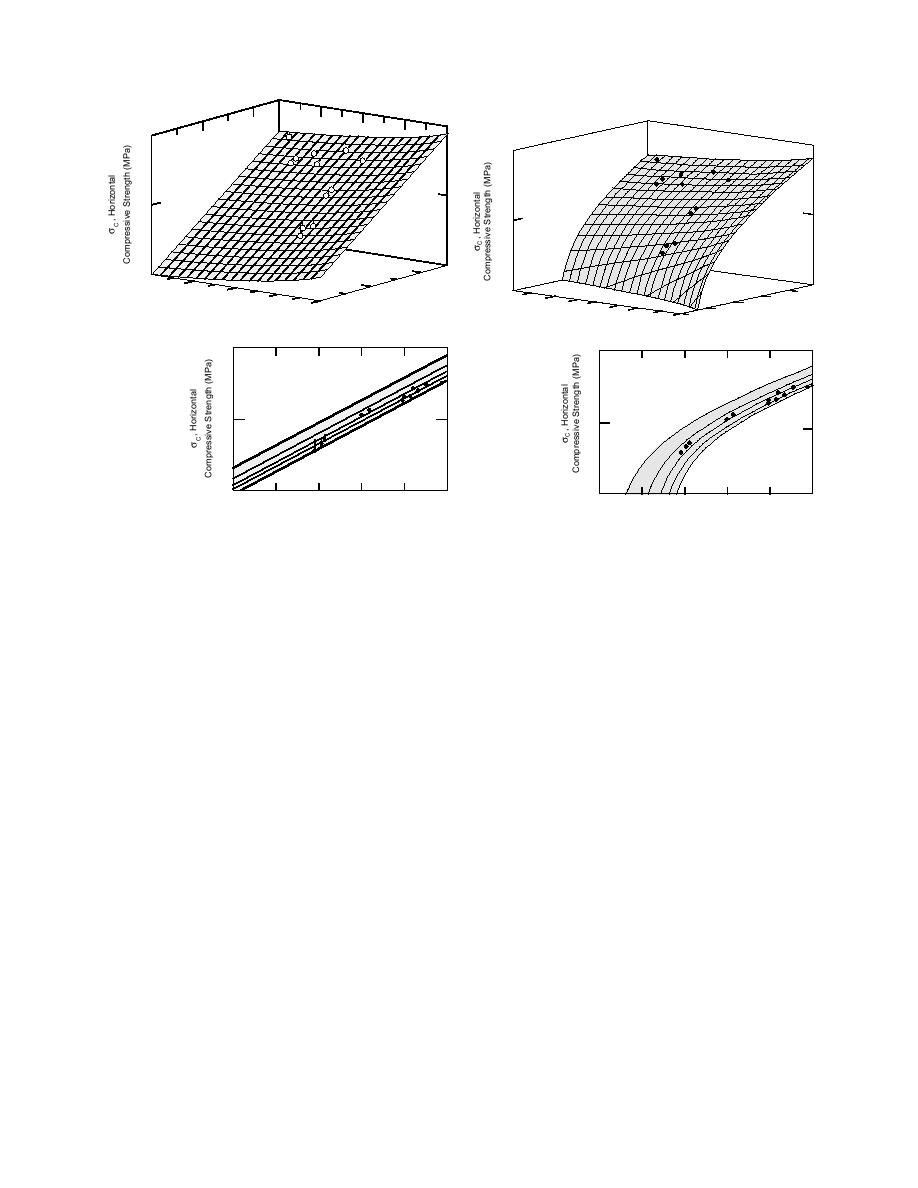

Figure 18. Equation-8-determined ice floe σc strengths

Figure 19. Equation-8-determined ice floe σc strengths vs.

vs. bulk porosity and strain rate (a) and the boresight

bulk porosity and strain rate (a) and the boresight view of

view from the above strain rate window (b).

the above from the strain rate window (b).

low a strain rate of about 106 the failure surface

18b. The three data points at a strain rate of

should be linear, a ≈ 3. However, the existing data

about 106 are shown to be offset from their

predicted failure surface position at the tip of

are insufficient for developing this trend. In the

interim, for strain rates between 104 and 103, the

their vertical tails, suggesting that the failure

surface curves downward. This is not surpris-

equation given in Figure 18 is preferred because it

ing if B contains a nonlinear viscosity compo-

does not contain a second constant. The equation

for the failure surface when νB is substituted for

nent. In this case, while stress is still a func-

φB in Figure 18 is σc = 150.75 ε0.31 νB0.36 . In this

˙

tion of strain rate, it is not directly proportional

(Mellor 1986), at least at strain rates between

volume or the porosity. In using either σc ex-

about 105 and 103 as indicated by the stress

vs. strain rate curves for fresh and saline ice

pression, the only parameters needed are the load-

given in Sanderson (1988). The Exxon data

ing strain rate and the bulk ice porosity or brine

fall in the ductile-to-brittle strain rate transi-

volume. The latter may one day be estimated from

tion region where the creep power-law may

remote conductivity measurements along with ice

not be valid, that is, ε ≠ Bσn because n is no

˙

thickness using a helicopter-borne electromagnetic

longer a constant.

induction sounding system (Kovacs and Holladay

A statistically more representative failure

1990).

A comparison of the σc data derived from us-

surface for the data is shown in Figure 19a.

This curved surface fits the data with a cor-

ing eq 8 with the horizontal uniaxial unconfined

relation coefficient of r2 = 1.000. A boresight

compressive strength data of others should be of

view of the data from the strain rate window

interest. The data compiled by Sanderson (1988;

in Figure 19a is shown in Figure 19b. Based on

see his Fig. 4.8) are shown in Figure 20 for the

the data presented by Sanderson (1988), be-

strain rate range of our data. In this standard

11

Previous Page

Previous Page