0.9

0.8

0.7

0.6

0.5

0.4

0.3

24 (C-days)

4

8

12

16

20

0

40 (F-days)

0

8

16

24

32

Weighted Average of Degree Days

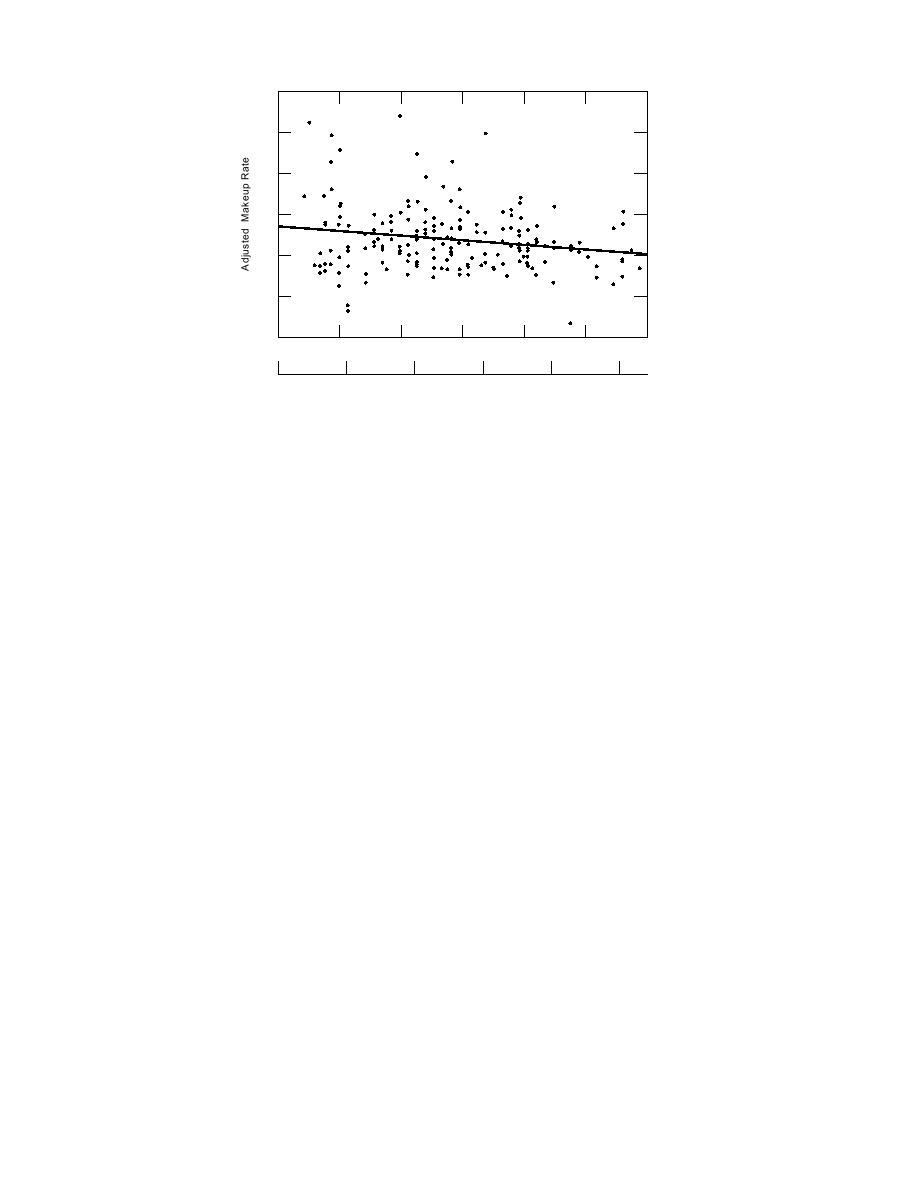

Figure 4. Adjusted makeup rate as a function of degree days.

the slope of the regressed function. It is fairly cer-

function has also been regressed onto these data.

The r2 for this regressed function is only 3.7%, how-

tain, however, that most of the variable portion must

be due to the condensate return system or lack

ever, so it cannot be considered statistically signifi-

thereof. Since leaks in the steam supply piping and

cant. The average of all the adjusted makeup rate

terminal equipment were not prevalent during site

data for the entire study period is 54%.

visits, most of the fixed portion of the leakage can

also be assumed to be in the form of condensate.

Conclusions regarding the

Since the condensate has a much lower enthalpy

Hawthorne AAP steam system

than the steam, on a unit mass basis, the condensate

With limited data we have constructed some

leaks are of much less consequence than steam leaks

estimates of the thermal and mass losses from the

would be. If we assume that all the mass loss is in

Hawthorne AAP steam heat distribution system.

the form of condensate, the equivalent energy loss

These estimates indicate that losses from the system

would be the difference between the enthalpy of the

are very high. Our estimates indicate that only 43%

condensate and that of the makeup water multiplied

of the steam leaving the plant is ultimately used for

by the total mass loss from the system over the

required space heating. The remainder (57%) is con-

study period. From the regression equation the total

sumed in steam and condensate leaks, heat losses,

mass loss is found to be 9,601,000 kg (21,234,000

and unnecessary overheating of buildings due to

lbm) and the enthalpy difference is 255.6 KJ/kg

poor control. Most of these losses would be drasti-

(109.9 Btu/lbm), so that the total equivalent energy

cally reduced if a low temperature hot water heat

loss from this mass leakage is 2,450 GJ (2,334 MBtu)

distribution system were retrofitted to Hawthorne

for the study period. If 10% of the mass loss were to

AAP. For example, Werner (1984) reports the heat

be in the form of steam the equivalent energy loss

losses from six Swedish low temperature hot water

would be nearly double at 4,820 GJ (4,588 MBtu).

heating systems as ranging from 4.9% to 7.7% of the

The most common measure of distribution sys-

total heat production, with the average being 6.6%.

tem leakage is the makeup rate, as discussed earlier.

It is also clear from Werner's (1984) data that the

We have adjusted the makeup rate by subtracting

heating load drops to 10%, or less, of its maximum

the makeup flow required for boiler blowdown.

value during times of low load. Since this includes

This yields a more representative picture of the mass

domestic tap water heating as well as distribution

system heat losses, it is apparent that control of the

losses in the distribution system and terminal equip-

building heating systems on a low temperature hot

ment. Figure 4 shows the adjusted makeup rate as a

function of the weighted average degree days accu-

water system must be much more effective than on

mulated for each day of the study period. A linear

the Hawthorne AAP steam system. Based on the

11

Previous Page

Previous Page