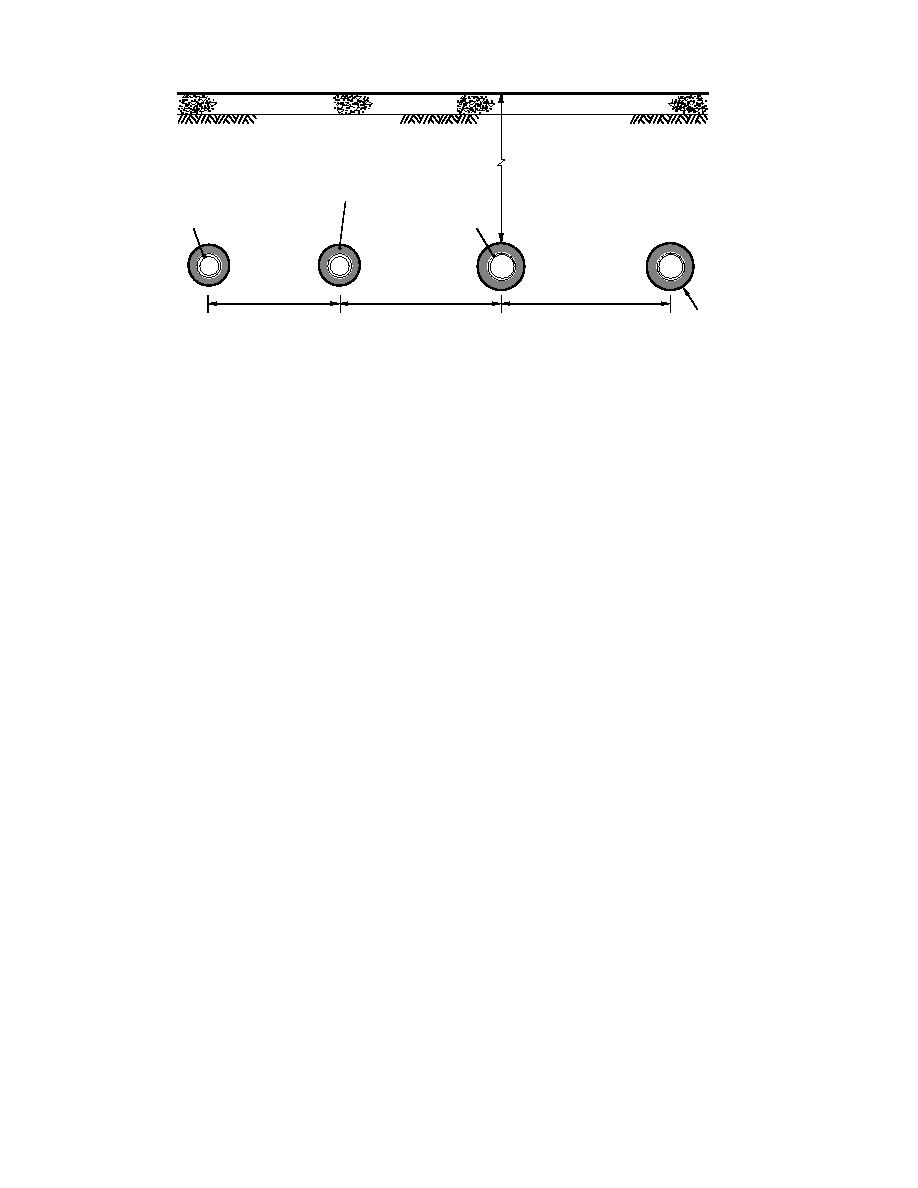

100 mm (4 in.) Concrete Slab

Silty Gravelly Sand

32 mm (1.25 in.)

2.41 m (7.9 ft)

Polyurethane Insulation

~100 mm (4 in.)

~75 mm (3 in.)

PVC Pipes

Steel Pipes

Supply

Return

Return

Supply

HOT

CHILLED

WATER

WATER

54.6 cm

63.5 cm

66.0 cm

2.5 mm (0.1 in.)

(21.5 in.)

(25 in.)

( 26 in.)

FRP Jackets

Figure 9. Construction details for the LTHW site 2.

more than one of the three system types while oth-

Instrumentation, data logging

ers are applicable for only one type of system. Each

and communication systems

The instrumentation consists primarily of type T

of these methods will be briefly described here and

copperconstantan thermocouples constructed

the systems for which each is applicable will be

from 20 AWG thermocouple extension wire. De-

given. More detail on the actual methods used is

tailed information on the location of the 167 thermo-

included in Phetteplace et al. (1991). Worked exam-

couples used on the MTHW sites at Ft. Jackson can

ples of heat transfer calculations for these types of

be found in Phetteplace et al. (1991). A report cur-

systems may be found in Phetteplace and Meyer

rently in preparation will describe in detail the in-

(1990).

strumentation of the Ft. Irwin LTHW sites. Heat flux

sensors were used at all sites, but the results from

Insulation method

these are inconclusive for reasons described

This method is applicable to all system types.

in Phetteplace et al. (1991). On each of the systems

With the observed temperatures on the inside and

instrumented, one site along the length of the sys-

outside of the pipe insulation, the heat flow through

tem was selected. Each of the sites at Ft. Jackson was

the insulation can be easily calculated using the

located at least 7.5 m (25 ft) from the closest manhole

standard formulas for a concentric cylindrical cross

and was chosen as representative of the remainder

section and the thermal conductivity of the insula-

of the system segment between manholes. On the

tion. In using this method on the MTHW systems,

LTHW system at Ft. Irwin, no manholes are used with

we assume that these temperatures are reasonably

all piping junctions buried directly in the ground. The

uniform around the circumference of the insulation.

sites at Ft. Irwin are at least 2.4 m (8 ft.) from the

For the individual conduit system, this assumption

closest junction or change in direction of the pipes.

is supported by the data of Lunardini (1989). Air

Three microprocessor-controlled data loggers

temperature measurements within the concrete

were used in this study. Each of these units was

trench and common conduit systems in this study

equipped with an RS-232 interface and modem so

also support this assumption. For the LTHW sys-

that we could transfer the data from the field sites at

tem at Ft. Irwin, temperatures are measured at four

equally spaced points around the perimeter of the

Ft. Jackson and Ft. Irwin directly to our personal

piping system. These temperatures are then aver-

computer at CRREL for processing. Again, more

aged and subsequently used to find the heat flow.

details on the extent of the data collected at Ft. Jack-

son can be found in Phetteplace et al. (1991), and for

Because of the difficulty of placing thermocouples

between the jacket and insulation of the LTHW

Ft. Irwin will be described in a future report.

system, temperatures are measured on the outside

of the jacket rather than at the outside of the insula-

Data analysis

Several different procedures are used to calculate

tion at these sites. An appropriate thermal resis-

the heat losses from the data collected at the five test

tance for the jacket has been added to the insulation

sites. Some of these procedures are applicable to

thermal resistance in these cases.

15

Previous Page

Previous Page