heated to about 21C (70F) the base temperature

late the remaining quantities. This information was

for the degree day calculation is taken as 18.3C

then transferred to a commercially available statisti-

(65F). For other types of buildings that are not

cal/graphical software package where the remain-

heated to as high a level, lower base temperatures

ing analysis was performed.

can be used. The portion of Hawthorne AAP un-

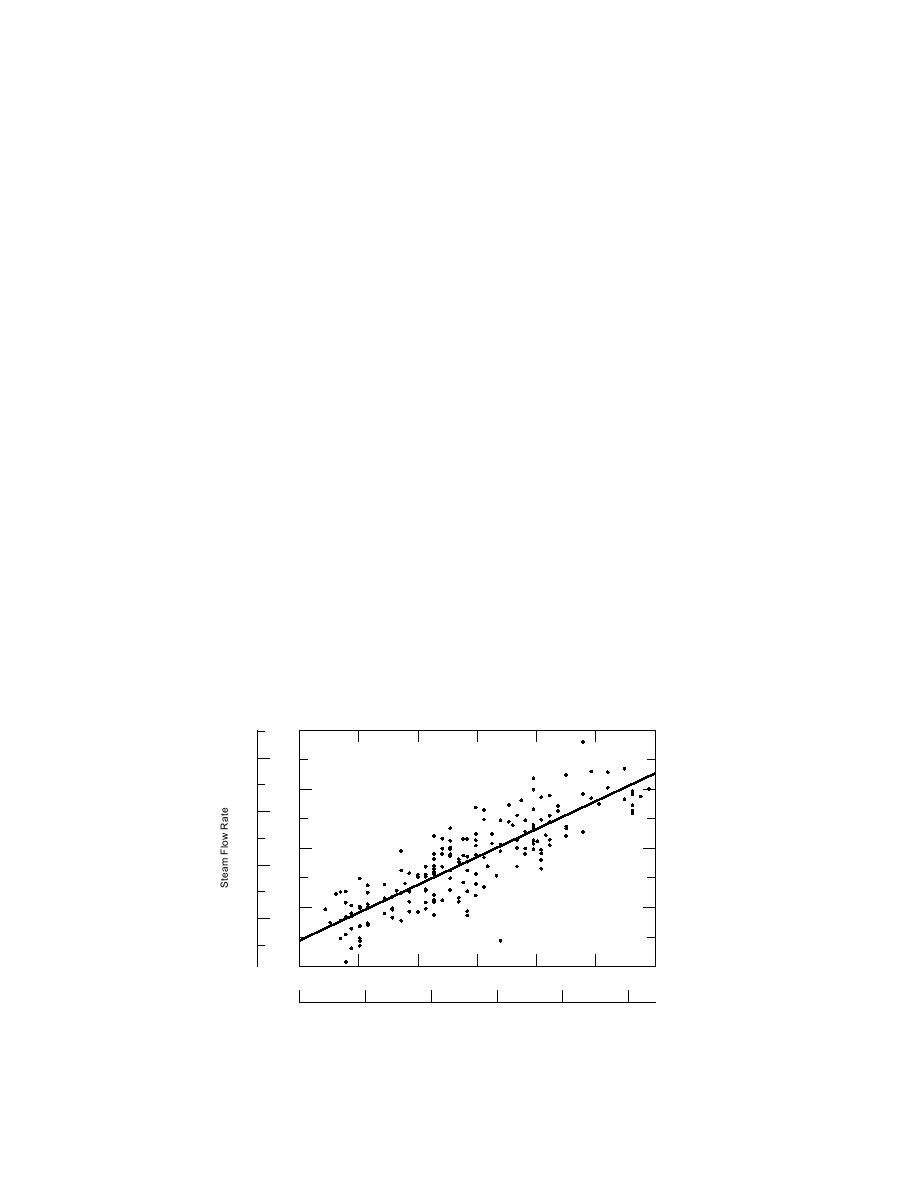

The first set of results we will present is intended

der study had residential and office buildings that

to enforce the premise that the heating degree day

would normally be heated to about 21C (70F) as

data provides a reasonable representation of the

well as shop type buildings that would not be

heat load from the buildings. Figure 2 shows the

heated to as high a level. In order to more accu-

average steam flow rate from the plant as a function

rately model the energy use of the shop build-

of the weighted average of the heating degree-day

ings, a base temperature of 12.8C (55F) was used

data. Although there is considerable scatter in these

for these buildings. The degree days were calcu-

data, they clearly support the concept of the degree

day. The r2 value for the linear relationship that was

lated on a daily basis for each of the two base

temperatures. These were then combined by form-

fitted to the data is 72%. Since this is the total steam

ing a weighted average of the two degree-day

flow from the plant, it represents all the losses from

figures obtained. The weighting factors used were

the system that would be manifested by steam con-

determined by taking the relative fraction of total

sumption as well as all energy consumption at the

floor area comprised by each building type. The

buildings. The components that make up the total

floor area of the residential and office buildings

steam flow out of the plant are the following:

comprised 63.2% of the total heated floor area

and the remaining 36.8% was from shop build-

1. Leaks from the steam piping into the envi-

ings. For the month of December 1987 the degree

ronment.

days computed for each of the two base tempera-

2. Heat losses from the steam lines that cause

tures, as well as the weighted average, are pre-

the saturated steam to condense. The con-

sented in Table 1.

densate is then subsequently drained from

the steam pipe and passes through a steam

trap into the condensate return system.

Results for the Hawthorne system

For each of the 181 days of the continuous

3. The heating load in the building that causes

period of boiler operation in the 1987/88 heating

steam to be condensed to meet this load.

Then the condensate passes through steam

season, the quantities in Table 1 were either mea-

traps into the condensate return system. Dur-

sured or calculated based on formulas presented

ing the time period when our data were

in Phetteplace (1991a). The measured data were

collected, no steam was used for domestic

input manually into a commercially available

tapwater heating.

spreadsheet program, which was used to calcu-

(lbm/s)

(kg /s)

2.0

4.0

1.6

3.2

1.2

2.4

0.8

1.6

0.4

24 (C - days)

0

4

8

12

16

20

40 (F - days)

0

8

16

24

32

Weighted Average of Degree Days

Figure 2. Steam flow from the plant as a function of degree days.

7

Previous Page

Previous Page