(lblb /ss) (kg /s)

( m/ )

1.0

2.0

0.8

1.6

0.6

1.2

0.4

0.8

0.2

24 (C - days)

0

4

8

12

16

20

40 (F - days)

0

8

16

24

32

Weighted Average of Degree Days

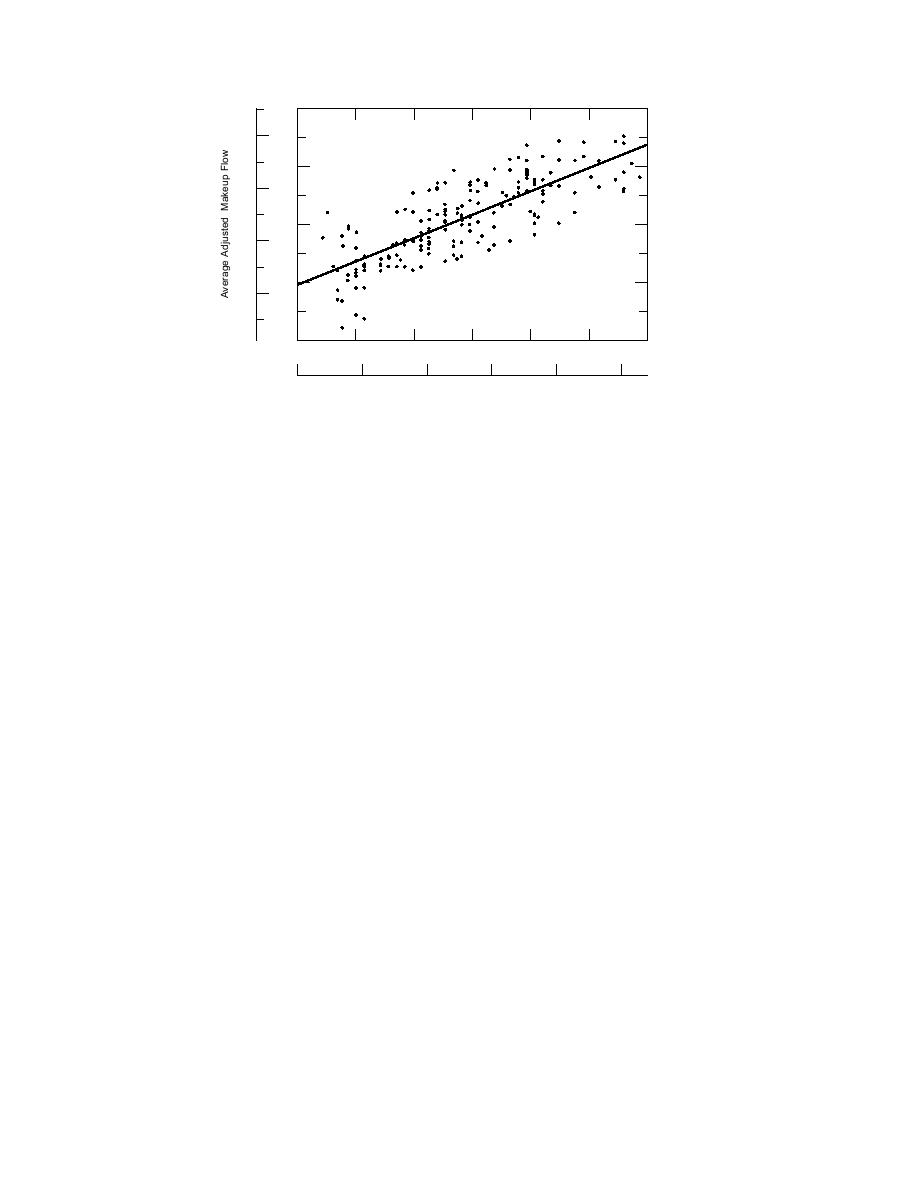

Figure 3. Adjusted average makeup flow rate as a function of degree days.

to heat losses and leaks as well as that unneces-

3. Condensate discarded at the consumers due

sarily used for building heating due to inadequate

to lack of a condensate return system.

control. This remaining quantity is found by mul-

4. Condensate leaks from the condensate re-

tiplying the intercept of the regressed line by the

turn system.

length of the period of the heating season under

study (181 days), the result being 10,368,000 kg

The first two sources of leaks listed, those in the

(22,832,000 lbm). Thus the total steam supplied was

steam supply line and the consumer's equipment,

18,159,000 kg (40,008,000 lbm). The distribution effi-

will be primarily functions of pressure and thus

ciency, that is the useful steam delivered divided by

fairly independent of heating load. To some extent

the total steam leaving the plant, is 42.9%.

this is also true of the leaks from the condensate

The amount of water which must be added to

return system. This system operates by gravity in

the system to account for that lost is called the

most places. The condensate return piping is in poor

makeup. The amount of makeup water is another

condition in many places, however, and larger flow

important measure of the efficiency of a heat distri-

rates can result in slightly higher pressures or more

bution system. Figure 3 shows the average makeup

completely filled pipes in cases where the pipes are

water flow rate as a function of the weighted aver-

not always flowing full. Thus, higher rates of leak-

age degree days accumulated for each of the 181

age could accompany the increased flow resulting

days in the study period. This makeup water flow

from higher heating loads. The remaining source of

rate has been adjusted to be more representative of

condensate loss, discarding at the consumer, will be

that due to losses in the distribution system and

highly dependent on heat load. With the exception

terminal equipment by subtracting the flow rate of

of the portion of the heat load that results from

water used in boiler blowdowns. Boiler blowdown

excessive building heating due to inadequate con-

is the term used to describe the periodic discharge

trol, all of the condensate loss from this source will

of water from the bottom of the boiler. This water is

be proportional to the load. A linear function has

discharged because it becomes high in contaminants

been regressed onto the data of Figure 3. The in-

as the pure water is boiled off.

tercept of this linear function is 0.390 kg/s (0.860

lbm/s) and its slope is 0.020 kg/s-C-day (0.0247

Mass losses in the distribution system and ter-

lbm/s-F-day). In this case it is more difficult to

minal equipment occur in the following areas:

determine what sources are responsible for the

1. Steam leaks from the steam supply piping.

"fixed" losses represented by the intercept portion

2. Steam and condensate leaks at the heat con-

of the regressed function and what sources are re-

sumer's terminal equipment.

sponsible for the "variable" losses represented by

10

Previous Page

Previous Page