TIRE MODELS FOR A DEFORMABLE

SUBSTRATE

Tire model construction

Background

To apply a tire model to deformable terrain, a

model is needed that is efficient yet accurately por-

trays the tire structural behavior. Specifically, an ac-

curate model of the contact patch is critical for simu-

lating the impact of deformable terrain on tire

performance. Models commonly used for tire design

purposes very accurately predict deformation of the

complete tire, including the interaction of the internal

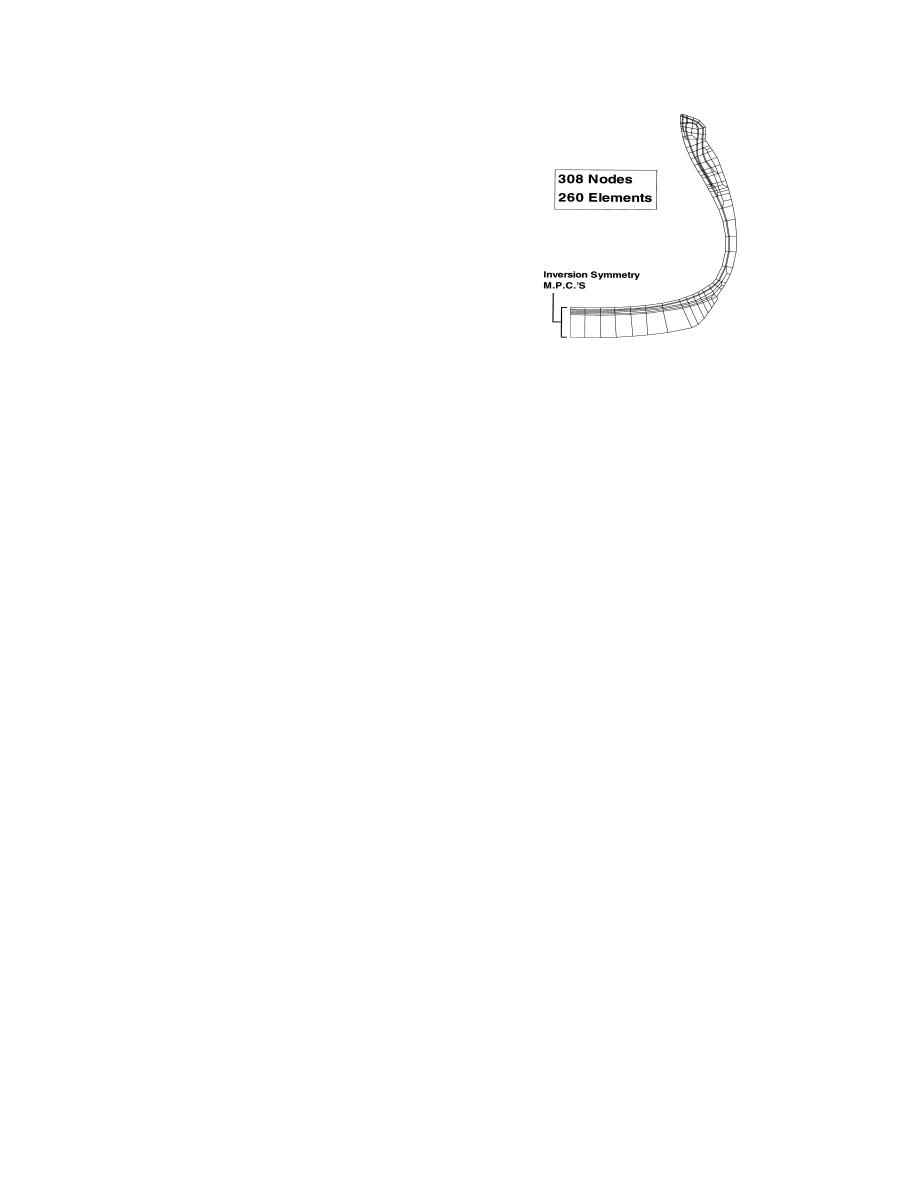

Figure 35. National Tire Modeling

components. However, since our concern is only the

Program (NTMP) model of a ra-

deformation as it relates to the contact region and its

dial tire. (After Danielson and

ability to roll across a surface, simpler models can be

Noor 1997.)

employed for better computational efficiency. To this

purpose, several tire models were evaluated for effi-

using methodology developed by Darnell at the Uni-

ciency and comparison to measured tire mechanical

versity of Michigan for use in vehicle dynamics, 3) a

response, particularly deformation and stress related

tire model of the type used for harmonic vibration

to contact.

modal analysis, with a smooth tread, and 4) a tire

Modern tires are structurally complex, consisting

model similar to model 3 except with a straight (lon-

of layers of belts, plies, and bead steel imbedded in

gitudinal) ribbed tread. The modal analysis models

rubber (Fig. 7). Materials are often anisotropic, and

were provided by Goodyear through a Cooperative

rubber compounds vary through the tire structure.

Research and Development Agreement and required

Models developed for tire design are extremely de-

only minor modifications to accommodate surface

tailed, modeling each material within the tire (belts,

contact and rolling. All of the models were built to

plies, rubber) for internal tire stress analysis, wear,

represent the tires used in the experimental test pro-

and vibration modal analysis. For these types of

gram for comparison to measured tire behavior in

models, the tire may consist of shell, continuum, and

terms of deflection, contact area, deflected sidewall

rebar elements. The simulation consists of mounting

profile, contact stress distribution, and performance

the tire on the rim, inflating it, lowering the tire onto

on deformable terrain (snow and soil).

a rigid surface, and applying various loading condi-

tions. Such models are extremely large and take

Tires simulated

many hours to run. The tire properties and associated

Three tires were involved in the data collection

modeling details for tire models used by industry are

phase of the project. The first tire was a Michelin

extremely difficult to obtain. Among the more nota-

XCH4 235/75 R15. This tire was used in several ex-

ble published contributions to tire modeling are nu-

periments on snow and soil under various moisture,

merous publications by Joseph Padovan at the Uni-

compaction, and temperature conditions. The second

versity of Akron (Padovan 1977, Padovan et. al 1992,

tire, a Goodyear Wrangler AT 235/75 R15, was cho-

Padovan and Padovan 1993, 1994a, 1994b) and mod-

sen to be similar to the first in construction and be-

els of agricultural tires by Hu and Abeels (1994). An

havior. The third was a highway tire with a ribbed

example of such a model is the National Tire Model-

tread pattern, the Goodyear Wrangler HT 235/75

ing Program (NTMP) radial automobile tire shown in

R15. The three tires were similar in size, construc-

Figure 35. The NTMP is a generic model used for

tion, deflection, and contact area characteristics, and

calibrating modeling programs across the tire indus-

data from all three were used in the following com-

try. Prior to 1997 this type of model required over 15

parisons. Although the tread patterns and compounds

CPU hours on a SUN SPARCstation 10 for inflation

varied (Fig. 36), which would strongly influence trac-

and no-slip contact on a rigid surface (i.e. no rolling).

tion, this study focused on the tire deformation and

In this research project, four types of tire models

rolling resistance, so the tires can be considered

were evaluated for suitability to rolling on deform-

equivalent. The dimensions of the test tires are given

able terrain: 1) a rigid tire, 2) a simplified tire model

in Table 6.

24

Previous Page

Previous Page