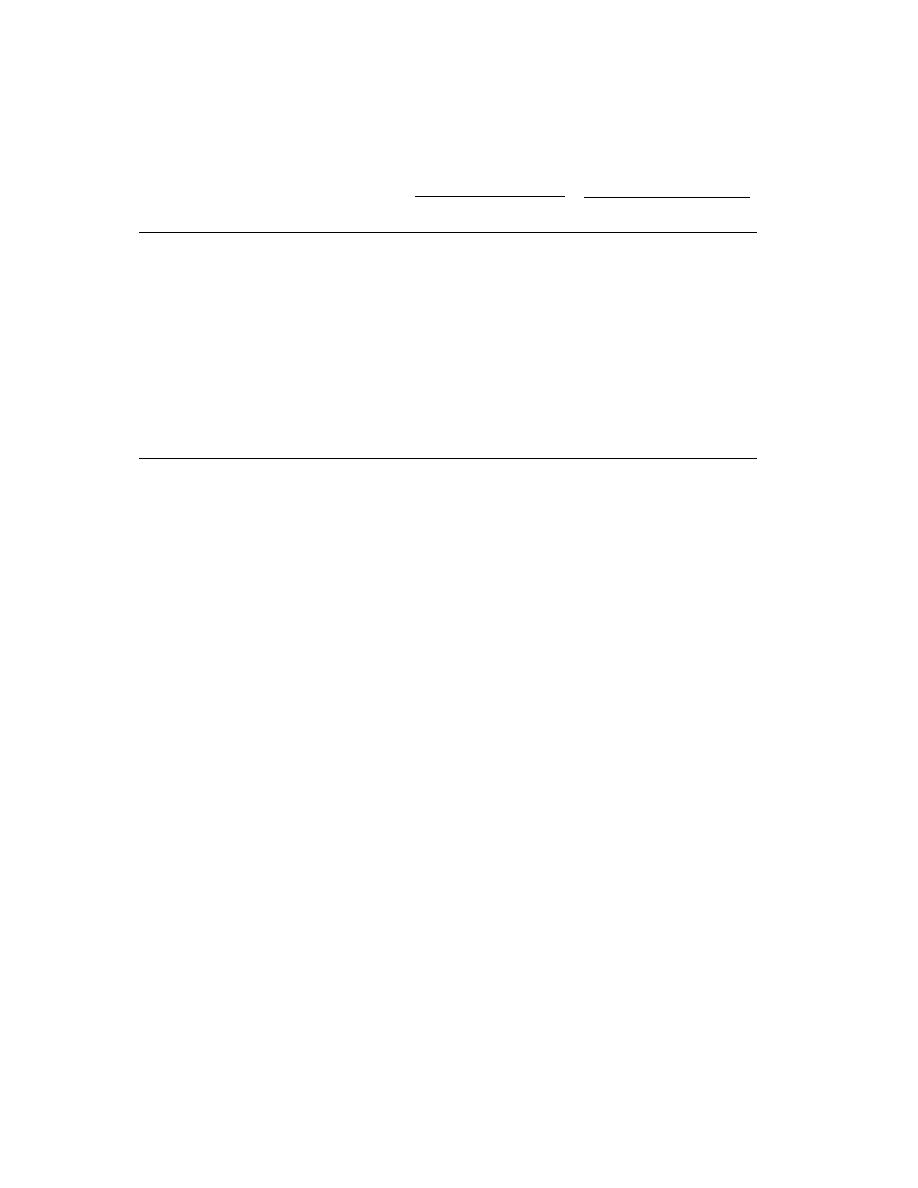

Table 3. Tensile modulus values of geotextiles at 5% strain and at failure based on informa-

tion in Geotechnical Fabrics Report (1996).

Construction,

K at 5% strain

K at failure

mass/area

(kN/m)/(lb/in.)

(kN/m)/(lb/in.)

(g/m2)/

(oz/yd2)

MD

XD

MD

XD

Product

Amoco 2044

W-PP, na

420/2400

760/4340

700/4000

875/5000

Carthage FX-400MF

W-PP, 427/12

386/2206

456/2606

542/3098

783/4475

Contech C-300

W/S-PP, 200/6

174/994

210/1200

306/1749

383/2186

Huesker Comtrac 800

W-PET, 1430/42

7200/41150

800/4572

7910/45206

667/3810

Linq GTF 550T

W-PET, na

404/2309

404/2309

876/5006

876/5006

Linq GTF 1000T

W-PET, na

1050/6000

1050/6000

1402/8012

1402/8012

Synthetic Industries

W/S-PP, 150/4

174/994

192/1097

233/1333

300/1715

Gtx. 200ST

Synthetic Industries

W/C-PP, 440/13

384/2195

454/2595

500/2858

583/3334

Gtx. 4 4

TNS W300

W-PP, 203/6

100/570

280/1600

290/1657

310/1772

USA Spantex 5710

K-PET, 2566/76

8000/45720

4000/22860

10000/57150

4167/23814

Webtec, TTHPG-50

W-PP, na

200/1143

220/1257

267/1524

260/1486

Webtec, TTHPG-57

W-PP

700/4000

700/4000

538.5/3078

487.5/2786

Notes: na = not available, W = woven, K = knitted, PP = polypropylene, PET = polyester, MD = machine direction, XD

= cross-machine direction.

the geotextiles when they are being used and to

Giroud and Noiray (1981) and from calculations

relate them to the values measured in tensile tests.

performed for this work. There is a difference be-

tween the curves generated for Figure 13 and those

from Giroud and Noiray (1981) for the 450 kN/m

geotextile being used for the 480 kPa tire pressure.

COMPARISON OF GIROUD AND NOIRAY

This difference is estimated to be about 10% at the

METHOD WITH ARMY METHOD

very lowest values of aggregate thickness. The

The tensile reinforcement advantages offered

reason for this discrepancy is unknown.

by high-strength geotextiles may offset the in-

creased cost. Therefore, the currently used Army

Stress distribution through the aggregate layer

design technique is compared with the design

Figure 14 shows the soil strength vs. aggregate

technique of Giroud and Noiray (1981) in this sec-

thickness curves for both design techniques with-

tion. Design curves provided in Barenberg et al.

out geotextiles for dual wheels on a single axle

(1975) and Giroud and Noiray (1981) for static

with wheel loads of 60 and 115 kN (13,500 and

loading were reconstructed to verify that the cal-

25,850 lb) and tire pressures of 414 kPa (60 psi).

culation techniques used for this work are accu-

These represent 10-ton and 20-ton trucks (e.g.,

rate. Design curves for the loading imposed by

Table 1). The Barenberg et al. (1975) method is more

typical military vehicles using each design method

conservative at these loading conditions, and this

are also presented to demonstrate potential aggre-

stems from the load distribution assumptions per-

gate savings by use of the Giroud and Noiray

taining to the spreading of the load beneath the

(1981) method.

wheels. Table 4 shows the maximum vertical stress

at various depths below the load for a wheel load

of 115 kN and contact pressure of 414 kPa using

Validation of calculation techniques

Design equations were programmed using

the Boussinesq stress distribution beneath a cir-

Mathcad 6.0 (Mathsoft 1995) to generate design

cularly loaded area (i.e., Newmark 1942) and the

curves. Details are given in Appendix B. Figure 11

trapezoidal stress distribution beneath a rectan-

shows the static load design curves from

gular load used by Giroud and Noiray (1981).

Barenberg et al. (1975) and points calculated for

Barenberg et al. (1975) used the Boussinesq

this work to verify the calculations. Similarly, Fig-

stress distribution because experimental and field

ures 12 are 13 are static load design curves from

work of others show that stress distribution

13

Previous Page

Previous Page