in.

m

0.5

)

n.

.)

2 i 6 in i n.) )

(

.

(

2

cm c m m ( (6 in

c

5

r= 1 5 r=5 cm

0.4

r=

15

15

r=

0.3

10

Field Trial:

0.2

r = 5 cm (2 in.)

r = 10 cm (4 in.)

r = 15 cm (6 in.)

5

Su = 30 kPa

(4.4 psi)

0.1

Austin et.al..)

et el

r = 5 cm (2 in.)

Su = 40 kPa

r = 10 cm (4 in.)

(5.8 psi)

0

0

0.5

0.4

15

0.3

10

0.2

.)

Field Trial:

)

5

in. 6 in

(2

(

r = 5 cm (2 in.)

0.1

m cm

5 c 15

r = 10 cm (4 in.)

=

r=

r

r = 15 cm (6 in.)

0

0

1

10

100

1000

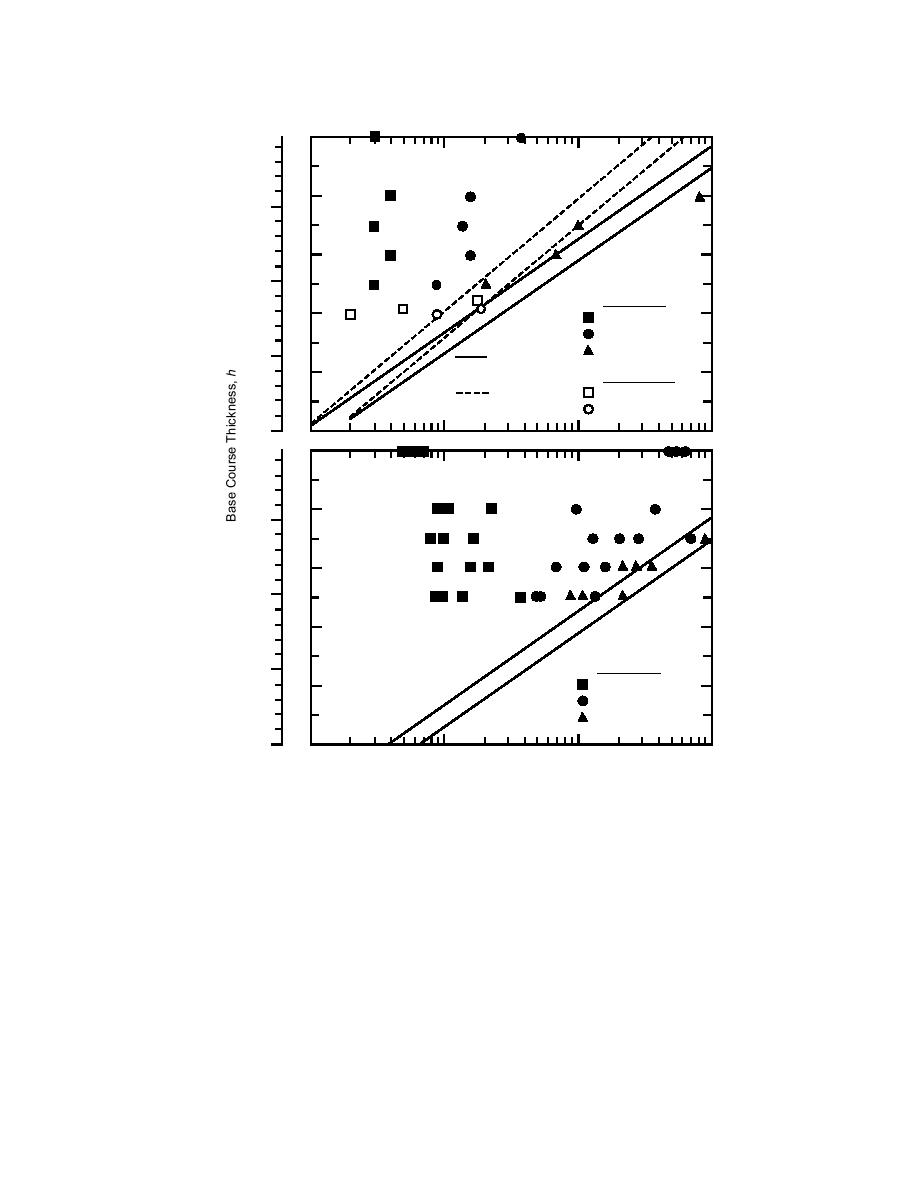

Figure 15. Field performance vs. theoretical prediction by Giroud and Noiray (1981)

for unreinforced test sections (top) and reinforced test sections (bottom). (From

Fannin and Sigurdsson 1996.)

The possibility of using Boussinesq stress dis-

the pressure measured in compacted clay-soil be-

tribution through the aggregate layer could be

low the rock layers was reasonably approximated

added to the Giroud and Noiray (1981) design

by a Boussinesq distribution beneath circular

technique. In addition, shapes other than a circu-

plates. Barenberg et al. (1975) based their theory

larly loaded area should be considered, and work

on tests that utilized "crushed stone aggregate,"

that examines stress distributions through aggre-

and, based on the work of McMahon and Yoder

gates other than crushed rock should also proceed.

(1960), a Boussinesq stress distribution through it

This would allow the confident use of design tech-

is a reasonable assumption for such an aggregate.

niques for relatively low-quality aggregate that

Unfortunately, Steward et al. (1977) did not de-

might be the only option for theater of operations

scribe the aggregate that was used in tests to vali-

date the Barenberg et al. (1975) design method.

military construction.

17

Previous Page

Previous Page