m

in.

1.0

35

Axle Load = 80 kN (18,000 lb)

0.8

Rut Depth = 0.2 m (8 in.)

30

Tire Pressure = 480 kPa (70 psi)

25

0.6

20

0.4

15

10

N = 100

0.2

N = 10

5

0

0

0

20

40

60

80

100

120 kPa

Undrained Shear

Strength 0

2

4

6

8

10

12

14

16

psi

CBR

0

1

2

3

4

m

in.

1.0

35

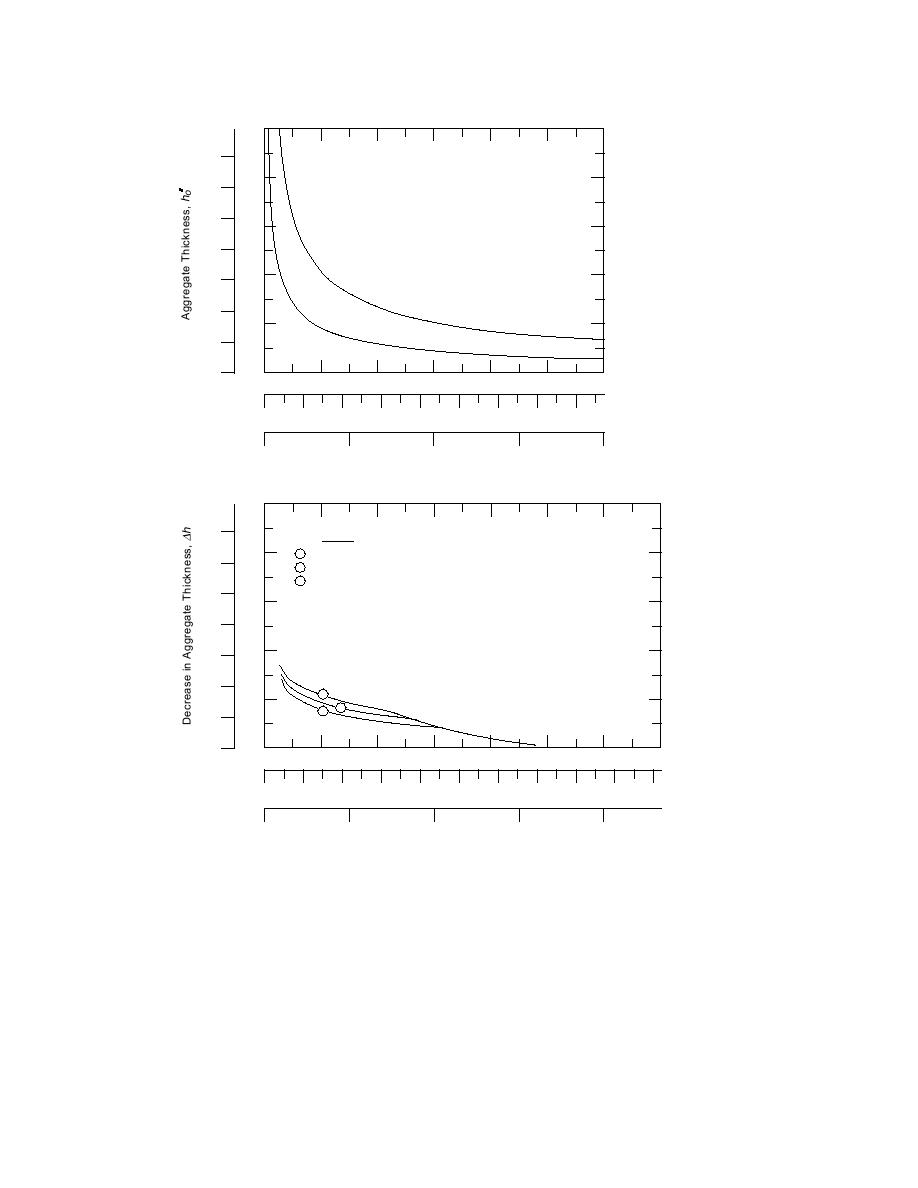

∆h for:

0.8

1 K = 50 kN/m

Axle Load = 80 kN (18,000 lb)

30

2 K = 200 kN/m

Rut Depth = 0.2 m (8 in.)

Tire Pressure = 480 kPa (70 psi)

3 K = 350 kN/m

25

0.6

20

0.4

15

10

3

0.2

2

1

5

0

0

0

20

40

60

80

100

120

140 kPa

Undrained Shear

Strength 0

16

18

0

Figure 7. Aggregate thickness, ho′ (top), and reduction of aggregate thickness, ∆h (bottom),

resulting from use of geotextile as a function of soil cohesion for 8-in. rut depth. N is num-

ber of vehicle passes and K is tensile modulus of geotextile. (From Holtz and Sivakugan

1987.)

aggregate layer should probably be a minimum

m (10 in.). The difference results from how each

of 0.10 to 0.15 m (4-6 in.) to prevent damage to

method estimates stress at the subgrade; this is

the geotextile as discussed below.

discussed in Theory, below, and in Stress Distribu-

tion Through the Aggregate Layer in the comparison

Notice that for the same conditions without

of the Giroud and Noiray and Army methods.

geotextile, less aggregate is recommended by the

Although the total amount of aggregate required

Giroud and Noiray design method than by the

by the two design methods is different, approxi-

Army method--0.2 m (8 in.) compared with 0.25

mately the same aggregate savings are realized by

8

Previous Page

Previous Page