tion that the subgrade soil is of a sufficient depth,

gregate cover of 0.15 m (6 in.).

Hmin, to allow the plastic zones associated with

Thus, the Giroud and Noiray (1981) technique

ultimate bearing capacity to develop. For the stress

is not generally applicable to thawed (or weak)

distribution assumed by Giroud and Noiray

layers less than 0.4 m (16 in.) thick, and the same

(1981), this amounts to

is assumed for the current U.S. Army design tech-

nique. If a geotextile is used and the full plastic

zones do not develop, the tension in the geotextile

B + 2h tan α

Hmin =

(6)

will not be fully mobilized. However, assuming

2

that the subgrade soil underlying the thawed soil

is stronger than the thawing soil, the support re-

where B is the width of the loaded area at the soil

quired of the geotextile will also be less than if the

surface (Fig. 9b), h is the thickness of the aggre-

subgrade were uniformly weak; and, therefore (as

gate layer, and α = (π/4) (φ/2), where φ is the

mentioned above), designing for reinforcement

with geotextile would be conservative. When the

friction angle of the base course expressed as ra-

thawed layer is so thin that full plastic zones can-

dians (Fig. 10). Giroud and Noiray (1981) assumed

the value of tan α to be 0.6. Assuming a dual-tired

not develop, the geotextile may provide impor-

tant separation between the thawing soil and the

truck with an axle load, P, having tire pressures,

aggregate that will likely lead to longer use of the

Pc, the width, B (m), of the wheel load is given by

road without maintenance.

(Giroud and Noiray 1981)

Other assumptions pertaining to the geo-

synthetic include that

P

B=

for off-highway trucks and

Pc

1. The geotextile does not fail,

2. The shape of the deformed geotextile consists

of parabolas (Fig. 8, bottom),

3. The aggregate will not slide along the geotextile

P 2

B=

surface,

for on-highway trucks.

(7)

Pc

4. The elongation, or strain, is uniform along the

entire length of the geotextile, and

5. The modulus of the geotextile, K, used in de-

Table 2 presents values for Hmin for a minimal ag-

e

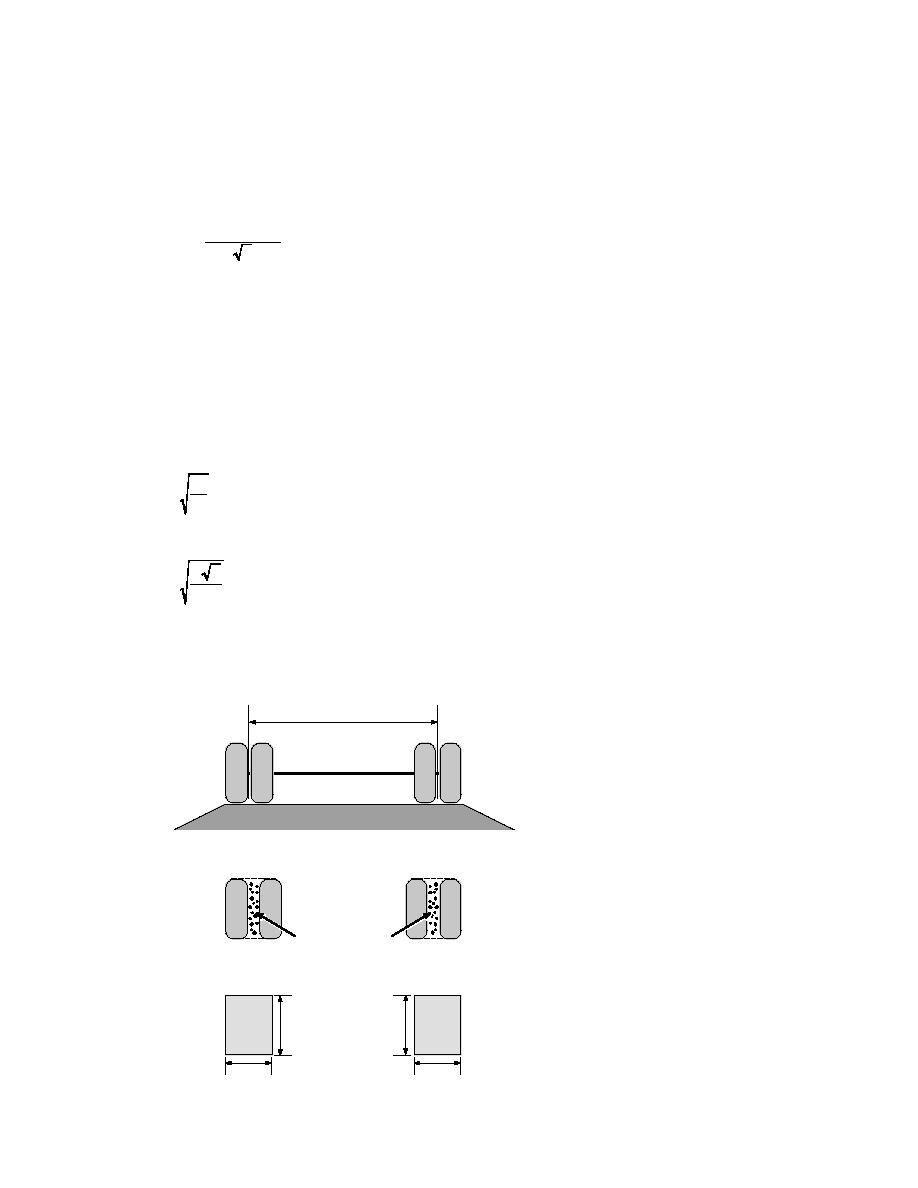

(a)

Aggregate

Figure 9. Definition of tire contact

area for dual tires (top), and equiva-

Ac

lent contact area used in analysis

(Giroud and Noiray 1981) (bottom).

(b)

(For single tires, L and B refer to

Soil mechanically

associated with

length and width of single tire print,

adjacent tires

respectively.)

L

L

B

B

10

Previous Page

Previous Page