in.

m

50

1.2

40

1.0

0.8

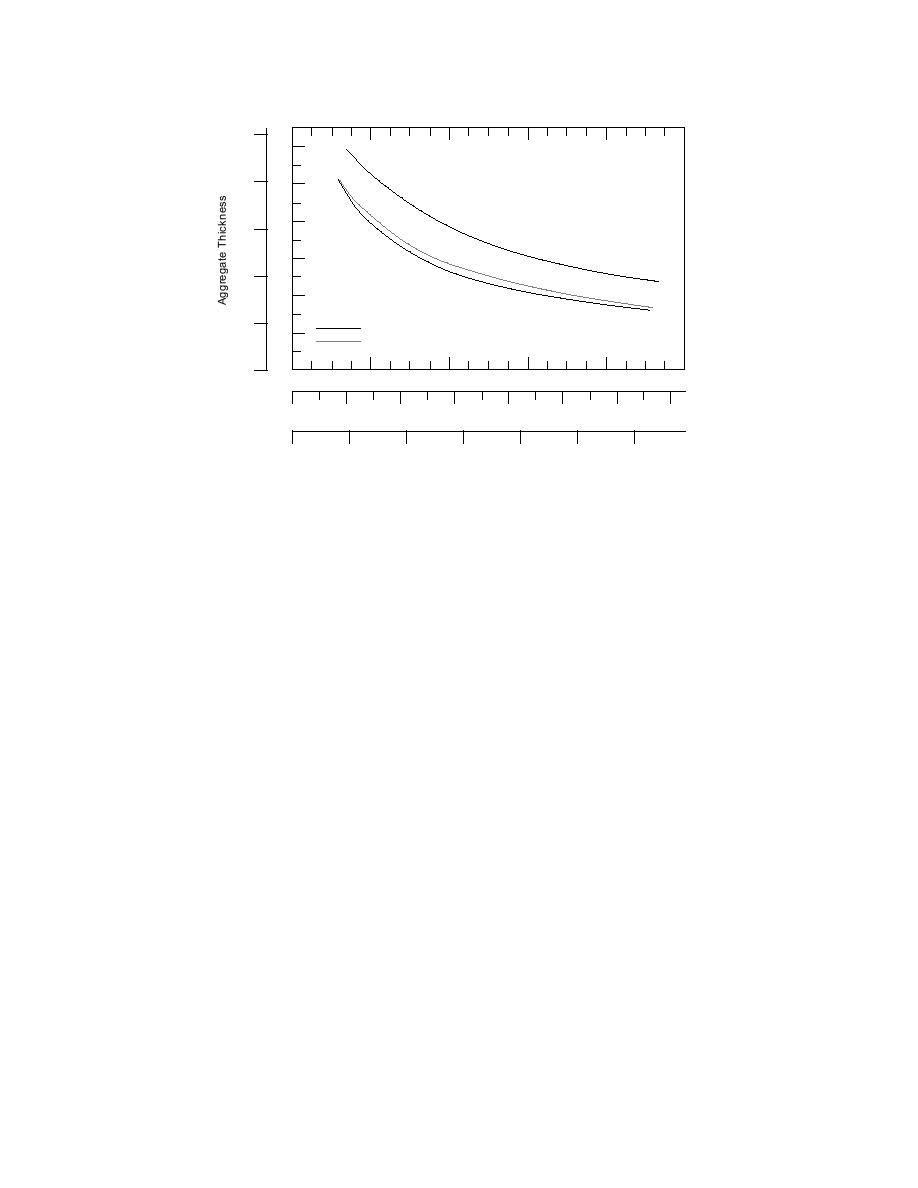

Without Geotextile

30

0.6

20

With Geotextile

0.4

10

Contact Pressure = 55.2 kPa ( 80 psi)

0.2

Contact Pressure = 103.4 kPa (150 psi)

0

0

0

10

20

30

40

50 kPa

Undrained Shear

Strength

psi

0

1

2

3

4

5

6

7

CBR

0

0.25

0.50

0.75

1.00

1.25

1.50

Figure 5. Design aggregate thickness chart for a 88.95-kN (20,000-lb) wheel load. (From

Barenberg et al. 1975.)

further loading of the same magnitude caused

However, localized plastic strains that can cause

negligible additional deformation. The unre-

localized shear failure begin at

inforced systems deformed progressively with

q ≈ πc .

repeated loading.

(3)

Barenberg et al. (1975) constructed design charts

for aggregate thickness vs. soil strength by assum-

Barenberg et al. (1975) conducted laboratory

tests (two dimensional, cyclic loading) with a

ing that the allowable pressure at the subgrade is

3.3c without geotextile and 6c with geotextile (Fig.

geotextile (Mirafi 140) placed between crushed-

5). Stress at the subgrade was calculated by using

rock aggregate and a saturated clay subgrade.

Boussinesq stress distribution beneath a circularly

Stress levels on the subgrade were estimated by

loaded area (Newmark 1942). The contact area, A,

using a Boussinesq stress distribution beneath a

was determined by dividing the wheel load by the

circularly loaded area (e.g., Newmark 1942), and

contact pressure. The radius, r, needed for deter-

ratios between the calculated subgrade stress and

measured soil strength were developed. The al-

mination of the stress at the subgrade surface, was

obtained from A = πr2.

lowable stress with geotextile on the subgrade

surface was

Barenberg et al. (1975) did not consider tensile

modulus or strength (or any mechanical property)

σzallowable = 6c .

(4)

of the geotextile in developing their design

method. Furthermore, even though Bender and

However, without geotextile, this relationship was

Barenberg (1978) note that "a layer of aggregate

material is always needed on top of the fabric to

σzallowable = 3.3c .

(5)

anchor it so that the necessary tensile forces can

be developed in the fabric" (p. 66), neither the

These numbers are very close to the theoretical

minimum depth for anchorage nor the mechani-

values of general and local bearing capacity fail-

cal properties of the aggregate layer are specified in

ure (eq 2 and 3). In addition to the change in fail-

either Barenberg et al. (1975) or Bender and

ure mode from local to general bearing capacity

Barenberg (1978). The effects of traffic loading when

failure, the soil systems that contained geotextile

vehicle passes exceed 100 were accounted for by

reached a level of permanent deformation so that

Steward et al. (1977) by reducing the Nc values.

5

Previous Page

Previous Page