0

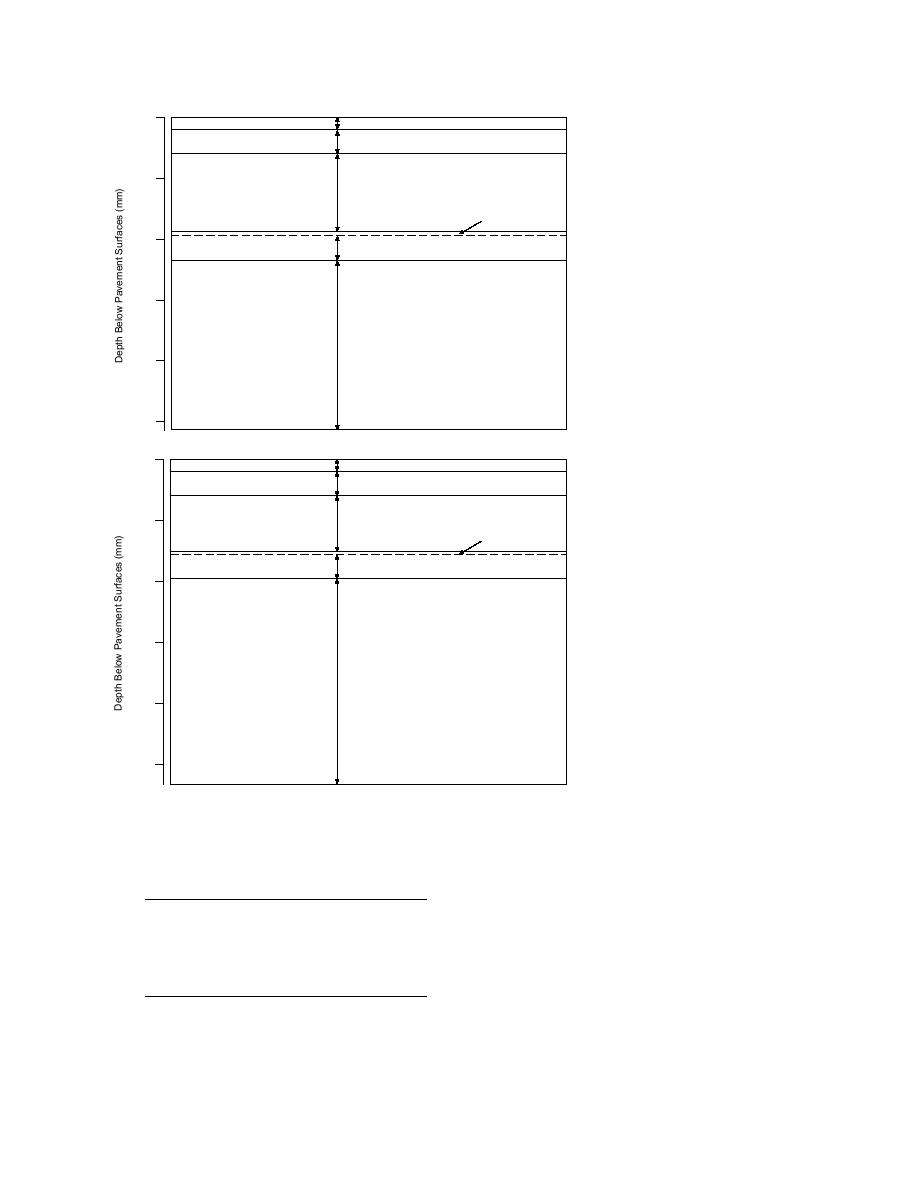

Asphalt Concrete

100 mm

Gravel Base

200 mm

500

Geosynthetic

Tilcon Material

640 mm

Liner Materials

30 mm

1000

Soil Gas

200 mm

Collection Sand

1500

1400 mm

Cement Treated Waste Material

2000

Figure 7. Pavement structure with

640-mm Tilcon layer modeled in

FROST.

2500

0

Asphalt Concrete

100 mm

Gravel Base

200 mm

Geosynthetic

500

Tilcon Material

460 mm

Liner Materials

30 mm

Soil Gas

200 mm

Collection Sand

1000

1500

1680 mm

Cement Treated Waste Material

2000

Figure 8. Pavement structure with

460-mm Tilcon layer modeled in

2500

FROST.

depths farther from the freezing front, the node

Table 2. Criteria for determining frost-

spacing can be farther apart without loss of accu-

susceptibility test.*

racy. The nodes were spaced 40 mm apart

8-hour

Bearing ratio

through the subgrade layer of the waste material.

Frost-susceptibility

heave rate

after thaw

Tables 35 show the number of elemental lengths

classification

Symbol

(mm/day)

(%)

used in each layer in all the simulations.

Negligible

NFS

<1

>20

The first two computer simulations were

Very Low

VL

1 to 2

20 to 15

designed to predict the frost effects in the pave-

Low

L

2 to 4

15 to 10

ment structure with the Tilcon common granular

Medium

M

4 to 8

10 to 5

High

H

8 to 16

5 to 2

fill material through the freezing season. As

Very High

VH

>16

<2

shown in the laboratory frost heave tests, the Tilcon

*Typical CBR for fine-grained soils such as clays, silts,

material, when saturated, may be considered a

and fine sands usually range between 3% to 15%.

highly frost-susceptible material. Since the graded

Coarser materials (sand-silt-clay combinations and

aggregate base has a lower frost-susceptibility,

gravelly sand) range from 10% to 40%. Gravelly clays,

gravel-sand mixtures, and well-graded gravels can

the depth was increased from 203 to 560 mm to

range between a CBR of 20% to 80%.

6

Previous Page

Previous Page