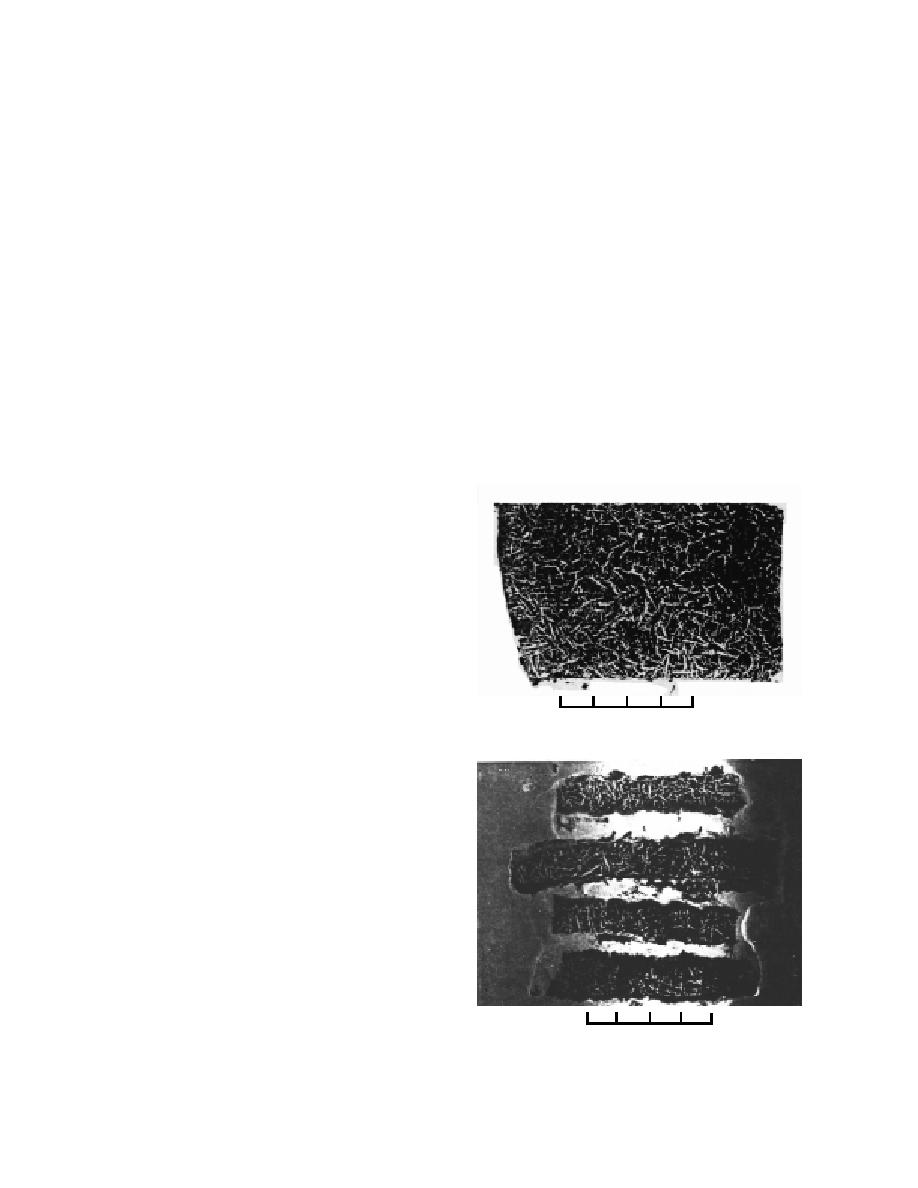

interesting result, as the thin sections (examples

the natural clay test pads. Ice lenses and shrinkage

cracks were not as prevalent as they were in cores

in Fig. 14) showed many randomly oriented ice

from the natural clay test pads. The ice appeared

lenses surrounding aggregates of bentonite. In

just as crystals in the sandbentonite matrix. Fur-

contrast to the low swelling characteristics of the

thermore, excavations into the sandbentonite test

Parkview and Valley Trail clays, the bentonite has

pad after thawing in both years revealed no blocky

a great affinity for water, even after freezing and

structure caused by ice lenses and shrinkage

thawing. The difference is attributable to the

cracks, as was observed for the clay test sections.

highly swelling nature of the "smechtite" clay

Uniformity of the percentage of bentonite

mineral in bentonite and the relatively low swell-

appeared to have a greater effect on hydraulic con-

ing characteristics of the clay minerals in the com-

ductivity of the sandbentonite than did freeze

pacted clay soils. This caused a reversal of the

thaw. Laboratory tests done at UW-Madison indi-

segregated structure formed during freezing of

cated that higher hydraulic conductivity in the

the GCLs and complete recovery of the hydrated

large-diameter sandbentonite specimens was

structure that restricts the flow of water through

caused by preferential flow through paths contain-

the GCL systems.

ing less bentonite. Piping (formation of channels)

The bentonite continued to hydrate under the

low surcharge stress (1 lb/in.2 [6.9 kPa]) during

appeared in each of the UW-Madison tests and in

some of the tests done in the CRREL laboratory.

the hydraulic conductivity tests, both before and

Additional observations of the sandbentonite,

after freezing and thawing. The swelling made

after the field permeameter was disassembled,

the hydraulic conductivity determinations diffi-

showed that the bentonite in the near-surface

material had become soft and was wetter than that

deeper in the section. Specimens removed from

depths of 3, 5.5, and 8 in. (8, 14, and 20 cm) showed

water contents of 42.1, 20.4, and 18.2%. The high

water content at the surface is attributed to hydra-

tion of bentonite and swelling because of low con-

fining pressure. This swelling also caused prob-

lems in doing the laboratory hydraulic conductiv-

ity tests. There was little or no flow of water

through the test specimens because of the low

effective stresses used and the continuous swell-

ing of the sandbentonite mixture. Since the deter-

mination of the hydraulic conductivity required

0

1

2

3 4 cm

the measurement of the flow of water both into

a. Horizontal.

and out of the test specimens, and since the flow

rate of water was very slow for the low hydraulic

conductivities measured, the swelling would

mask the outflow and result in artificially high

inflow rates. Thus, a considerable amount of time

was required for the swelling to diminish and the

inflow and outflow volumes to balance. Higher

confining pressures than typically used (about 1

lb/in.2 [6.9 kPa]) in laboratory hydraulic conduc-

tivity tests would have reduce the swelling prob-

lem. However, the laboratory tests reported here

intentionally used low confining pressures com-

mensurate with those in the field tests.

Hydraulic conductivity of GCLs

Laboratory test results

0

1

2

3

4 cm

The laboratory test results on the GCL materials

b. Vertical.

showed almost no change in the hydraulic con-

ductivity from freezing and thawing. This was an

Figure 14. Thin sections of a frozen Bentomat GCL.

13

Previous Page

Previous Page