unique microstructures in the specimens

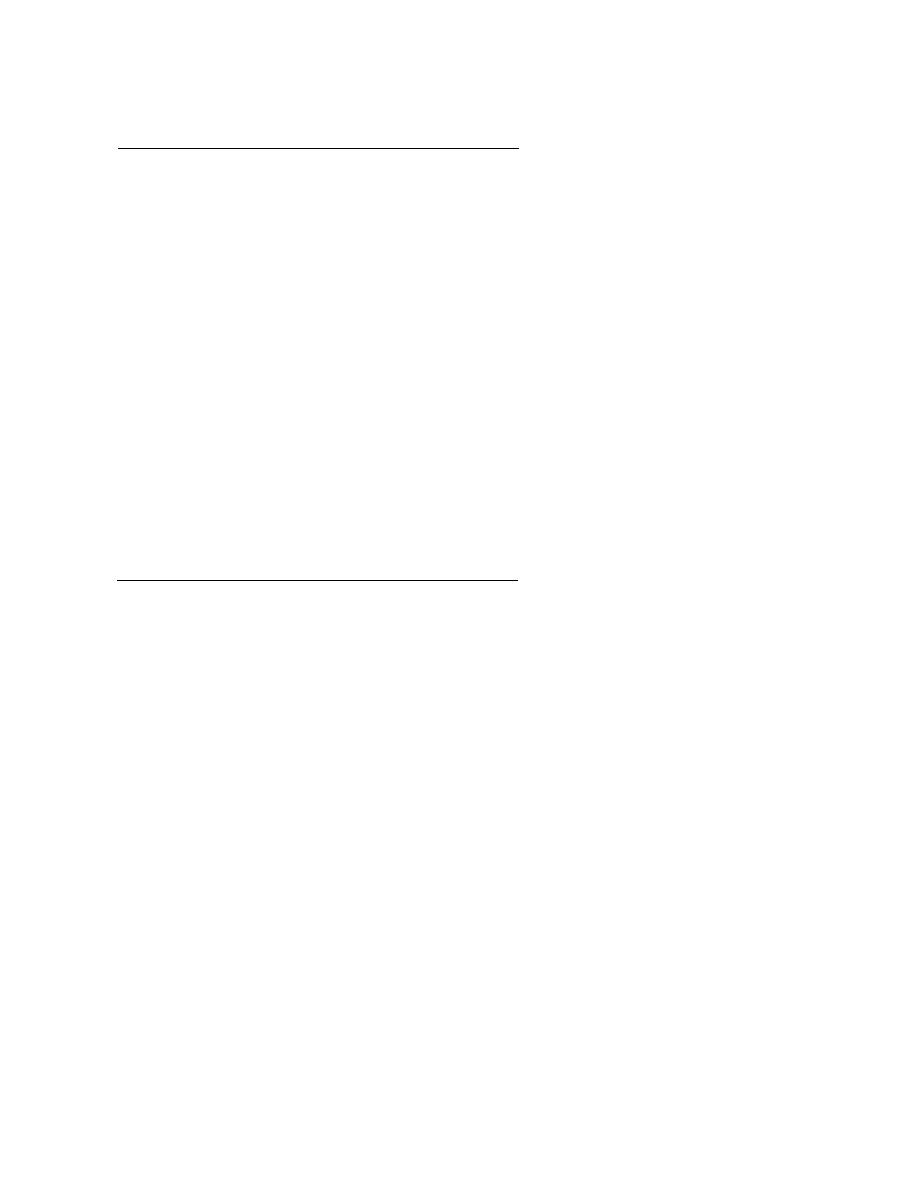

Table 10. Corrosion rates with various admixtures.

containing the antifreeze admixtures, as

Initial

2-year corrosion

Corrosion

compared to paste structures observed in

rate A/cm2

Sample

potential

control specimens. However, the speci-

no.

Admixture

(kohms/cm)

(mV vs. SCE)

(relative)

mens containing DP at 6%, and those con-

1A

Control

5.4

249

0.23

taining DPTC at 6% and at 8%, exhibited

1B

"

5.3

564

0.70

abnormally high concentrations of cal-

1C

"

5.5

536

0.28

cium hydroxide on exterior surfaces and

1D

"

6.1

91

0.05

1E

"

5.7

211

0.11

interior aggregate sockets. The abundance

1F

"

5.5

131

0.08

of calcium hydroxide suggests that sig-

Average

"

5.6

297

0.24

nificant bleeding may have occurred. The

2A

PolarSet*

3.4

86

0.06

control specimens, which contained only

2B

"

3.8

94

0.07

water reducer and air entraining admix-

2C

"

3.2

65

0.06

2D

"

3.2

76

0.06

tures, exhibited heavy concentrations of

2E

"

3.8

80

0.09

air-void clusters along the paste/aggre-

2F

"

4.0

75

0.05

gate bond interface. The mix design pa-

Average

"

3.6

79

0.07

rameters (such as water/cementitious

3A

DP*

5.2

108

0.07

material ratio, aggregates quantities and

3B

"

4.6

86

0.02

3C

"

4.5

121

0.05

qualities, and cement factor) were kept

3D

"

4.8

136

0.07

constant for all mixes. The admixtures

3E

"

4.3

97

0.06

used are listed in Table 11. Other than the

3F

"

4.8

73

0.05

differences noted above, the cement

Average

"

4.8

104

0.05

paste/aggregate bond interface did not

4A

DPTC*

4.4

114

0.06

4B

"

5.1

119

0.12

show any difference in composition or

4C

"

5.3

127

0.08

structure from those of the control speci-

4D

"

4.5

146

0.18

mens.

4E

"

4.6

113

0.19

Task 4: Alkali-silica reaction. The selected

4F

"

4.6

118

0.17

admixtures do not add sodium or potas-

Average

"

4.8

123

0.13

sium (the potentially harmful alkalis) to

*The given admixture was dosed at 6% of solids by weight of the water in

the concrete mix. Therefore, testing for

the solution.

alkali-silica reaction as planned was

found to be unnecessary, and was cut from the

ity and curing temperature, and 4) the type and

testing program.

amount of admixtures. A detailed microscopic ex-

Task 5: Air-void analysis. The air content and the

amination of concrete specimens containing se-

spacing factor are the main parameters that deter-

lected admixtures can provide insight into the ef-

mine to a large degree the freezethaw durability

fects that such admixtures can have on the

of concrete. In this task, the total air content of

compressive strength and long-term durability of

each mixture series was measured in both the fresh

hardened concrete.

and hardened states. The spacing factor, the aver-

The evaluation and characterization of the con-

age chord length, the number of voids per inch,

crete microstructure included both conventional

the specific surface, and the paste content were

and advanced imaging techniques. Preliminary

determined on hardened concrete specimens rep-

observations were conducted at relatively low

magnifications (< 75) on both fractured and pol-

resenting each of four mixtures. An air entraining

agent, Daravair, was dosed to produce an air con-

ished surfaces, using a stereomicroscope. More

tent of 57%. Also, a super plasticizer, WRDA-19

detailed and advanced imaging involved the use

of high magnification (1001000) reflected and

(Daracem 19), was dosed to produce a target slump

between 13 and 17 cm. The water/cementitious

transmitted light microscopy. The latter technique

was augmented by the use of ultrathin (< 30 m)

material ratio was 0.417. The air-void structure in

the hardened concrete was analyzed after 28 days

sections of the hardened concrete. Finally, scan-

of curing. The control specimens were cured at

ning electron microscopy (SEM) and energy dis-

normal room temperature, while all of the anti-

persive X-ray spectroscopy (EDXS) were used to

freeze test specimens were cured at 7C. The

analyze the hydration products in each specimen.

specimens were polished slabs cut from concrete

The results of a detailed microscopic examina-

cylinders.

tion did not reveal any evidence of unusual or

9

Previous Page

Previous Page