selection criteria at this stage were chiefly

Table 5. Chemical composition of best admixtures tested

in Phase 1.

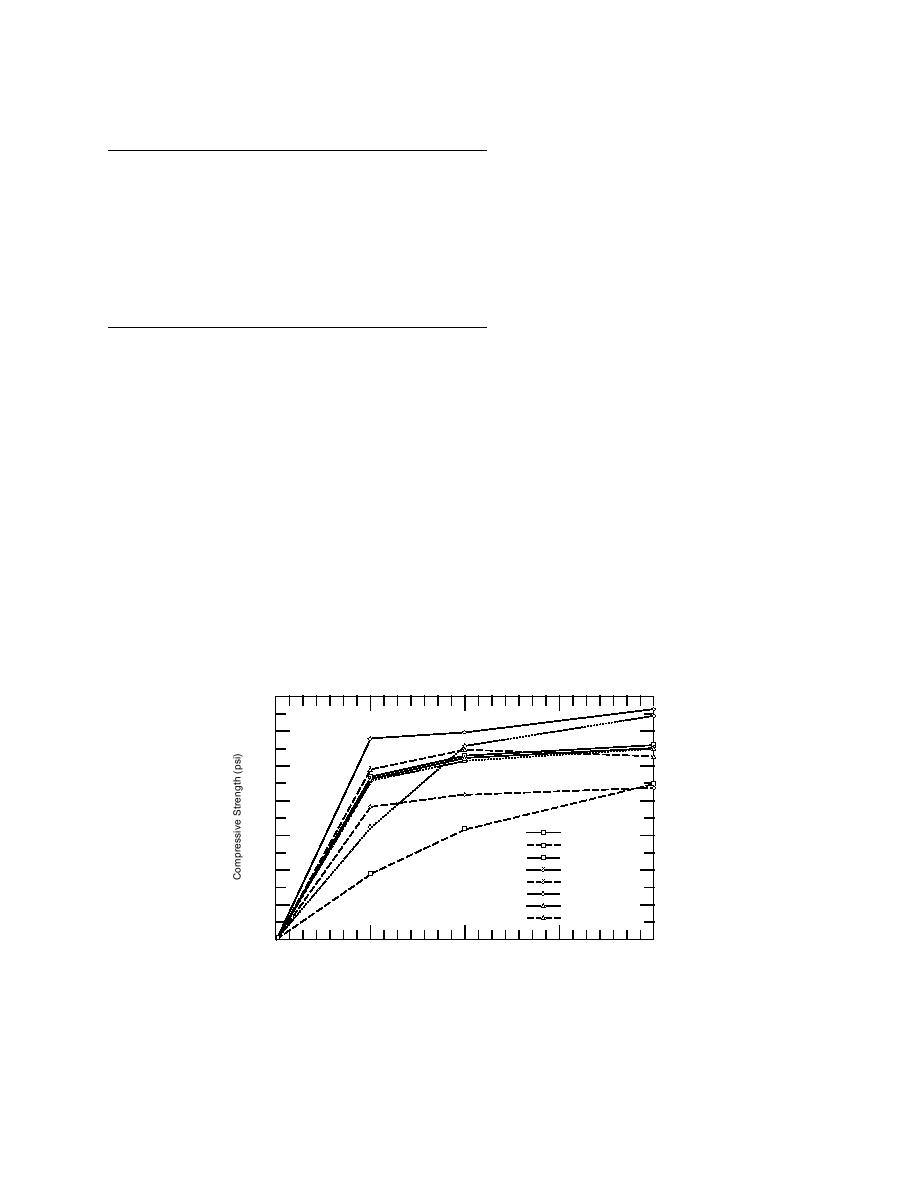

based on the strength developed at seven

days of cure at 5C. In these graphs each

Antifreeze admixture

Dosage

Water/cement

mixture is identified by a code. The first two

Mix no.

formulation

(% CWT)

ratio

characters indicate the task number for which

1A_1*

Control admixture-free

0

0.48

the test results were obtained followed by

1A_20

KC1 (3 parts of sodium nitrate

the mix number used in the corresponding

+ 1 part of sodium sulfate)

8.0

0.48

task. Figures 1a through 1d display the test

1B_19

CCSN

4.0

0.48

results at 20C, 5C, 10C, and 20C. Two

1D_4

K2CO2 + lignosulfonate

6.0/1.5

0.38

1D_7

Ca(NO2)2 + NaNO2

3.0/3.0

0.48

control curves corresponding to admixture-

CM-48†

6.0

0.48

1E_5

free concrete are included for reference. One

CM-42†

1E_3

6.0

0.48

corresponds to concrete cured at 20C. The

Ca(NO2)2 + WRDA-19**

1F_8

4.0/0.7

0.40

second corresponds to concrete cured at 5C,

DP†

6.0

0.43

1H_2

†

the lowest temperature currently covered by

1H_6

DPTC

6.0

0.43

the ACI 306 specification. Table 5 shows the

* 1A_1 means mix number 1 in task 1A.

chemical composition of the selected admix-

† Code name used only to protect proprietary rights.

tures. The admixtures subject to proprietary

** WRDA-19 is a high-range water-reducing admixture commercially

available from W.R. Grace, Inc.

rights are identified by their code name only.

Figure 1a, corresponding to a curing tem-

mens cured at 5C that was equal to or better

perature of 20C, shows that CCSN (Mix No.

than that of nonadmixture concrete cured at 5C.

1B_19) enhanced the strength of concrete for at

The admixtures that developed higher strength at

least the first 28 days. The admixture Ca(NO2)2 +

5C were selected for further testing in Phase 2.

NaNO2 (mix 1D_7) caused lower strength at seven

It is important to note that these temperatures are

days, but higher strength at 14 days and thereaf-

at the center of mass of concrete cylinders. In ac-

ter. The admixture K2CO2 + lignosulfonate (mix

tual concrete structures, the air temperature can

1D_4) reduced the strength at all times, at least up

be significantly lower without harming the con-

to 28 days. The rest of the admixtures did not

crete because of the effect of the internal heat of

have a significant effect at room temperature.

hydration.

Figure 1b, corresponding to a curing tempera-

ture of 5C, shows that most of the selected ad-

Analysis of Phase 1 test results

mixtures allowed concrete strengths to be between

the values for the 20C and 5C control concrete.

The strength performances of the selected ad-

mixtures are presented in the figures below. The

Any strength developed at low temperature that

7000

6000

5000

4000

Control +20C

3000

Control +5C

1A 20

2000

1B 19

1D 4

1D 7

1000

1E 5

1E 3

0

0

7

14

21

28

Concrete Age (days)

a. 20C.

Figure 1. Compressive strength of best admixtures of Phase 1 cured at

various temperatures. Mixes 1F_8, 1H_2, and 1H_6 were not tested at

20C.

4

Previous Page

Previous Page