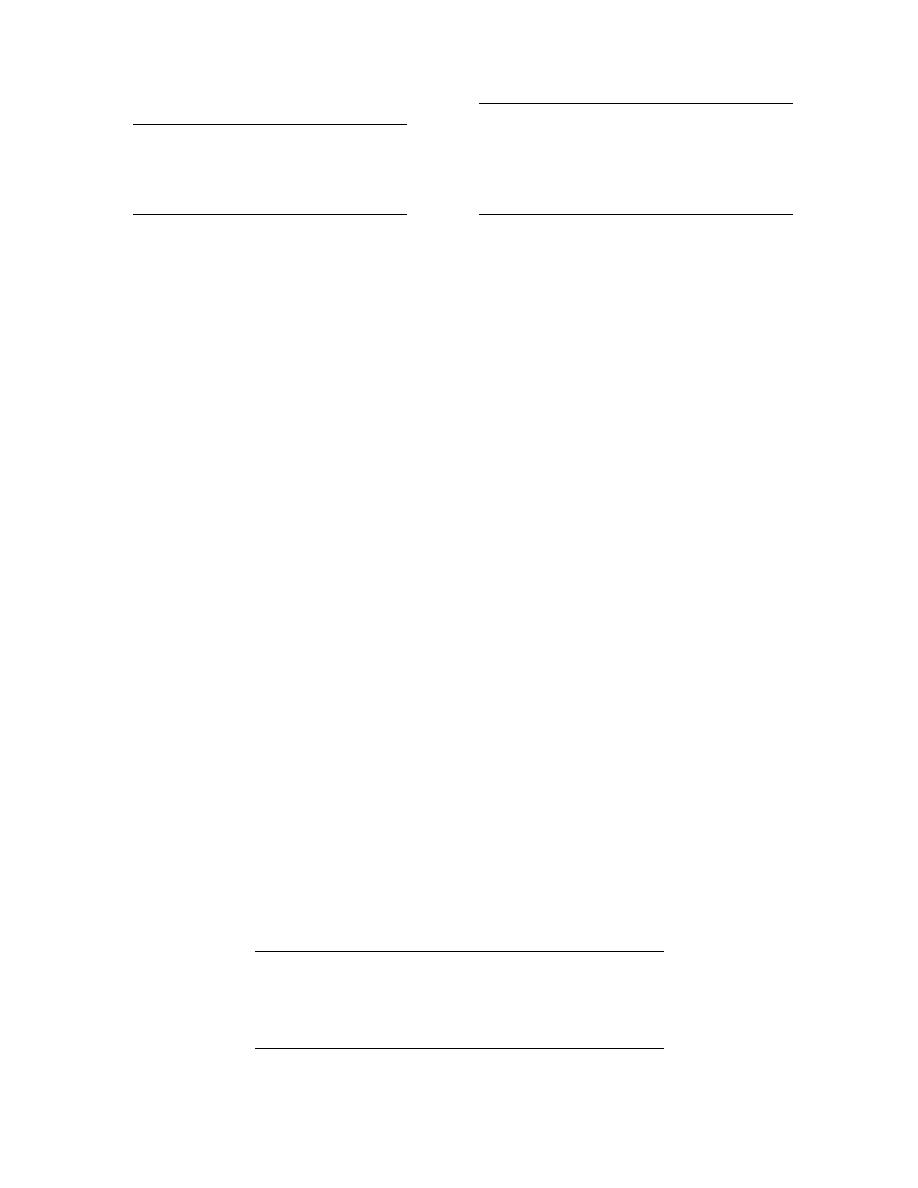

Table 2. Concrete mix design.

Table 1. Research work organization.

Cement type

ASTM C150, Type I

Phase no.

Description

362.8 kg/m3 for tasks 1A to 1F

Cement content

418.6 kg/m3 for task 1H

1

Effect of chemicals on strength gain

Water/cement ratio

0.48, or as indicated

2

Evaluation of best admixtures

Target slump

5 cm

3

Prototype slab-wall application

Aggregate gradation

ASTM C 33, # 6

4

Field application of new admixtures

Aggregate source

Lebanon, New Hampshire

5

Technology transfer

chemical formulations in search of an admixture

LABORATORY EXPERIMENTS

that would cause concrete to develop acceptable

strength at temperatures below 0C. Because cur-

Phase 1: Effect of chemicals

rent concrete construction standards cover con-

on strength gain

crete work down to 5C, the overall goal was to

produce an admixture that would promote con-

Objective

crete strength at 5C to meet or exceed the

To develop a chemical formulation that would

strength of admixture-free concrete at 5C.

allow concrete cured at 5C to gain strength at

least as fast as control concrete cured at 5C.

Another objective of this project was to recom-

mend changes that integrate the findings of this

research into relevant construction standards. It

Experimental approach

was the intention of the industry partner to de-

Early experiments with single chemical com-

velop an admixture that would provide adequate

pounds, experiences found in the literature,

strength at a sufficiently low temperature to jus-

physico-chemical data available for each chemi-

tify the investment involved in the implementa-

cal compound, and knowledge of the chemistry

tion of a new product line.

of cement hydration formed the basis for the for-

mulation of candidate admixtures. The candidate

admixtures were made of mixtures of two, three,

Approach

The research work was organized into five

or four chemical compounds. These formulations

phases (listed in Table 1). Phase 1 evaluated a

were tested for their ability to perform as anti-

large number of potential chemical compounds

freeze admixtures, i.e., chemicals that depress the

for their ability to promote concrete strength at

freezing point of water and accelerate the hydra-

5C. The admixtures that provided the best strength

tion of cement.

performance at low temperature were selected for

The experimental work began by screening a

Phase 2. This phase was a more comprehensive

set of chemical formulations using a strength gain

evaluation that included testing to determine the

criterion. A series of concrete mixes were made

effect of these chemicals on relevant concrete prop-

(Table 2), each including one candidate admix-

erties. Phase 3 consisted of a prototype concrete

ture at one of various dosages. A number of cylin-

application geared to explore practical job site is-

ders were cast and cured under one of several

sues such as placement, finishing, and curing of

temperatures using special coldrooms. Addition-

full-size concrete elements. Phase 4 integrated the

ally, control concrete (admixture free) was mixed,

experience gained in the prototype application

cast, and cured under the same conditions as the

into an actual field application built under winter

admixtured specimens (Table 3). At the prescribed

conditions; this demonstrated the advantage of

time, the cylinders were transported out of their

using antifreeze admixtures over conventional

coldrooms and allowed to thaw up to a controlled

temperature of about 10C at their center of mass.

thermal protection methods. Phase 5 consists of

technology transfer efforts, such as this report.

This was a necessary precaution to avoid testing

Table 3. Test parameters.

Chemical admixtures

As needed

(20C, 5C, 10C and 20C)

Curing temperatures

4

Testing ages

3

(7, 14, and 28 days)

0.04 m3

Mix size

Specimen replicates

3

7.6 cm 15.2 cm

Specimen size

Cylinders

2

Previous Page

Previous Page