Tension (kPa)

0

40

20

1

1

10

10

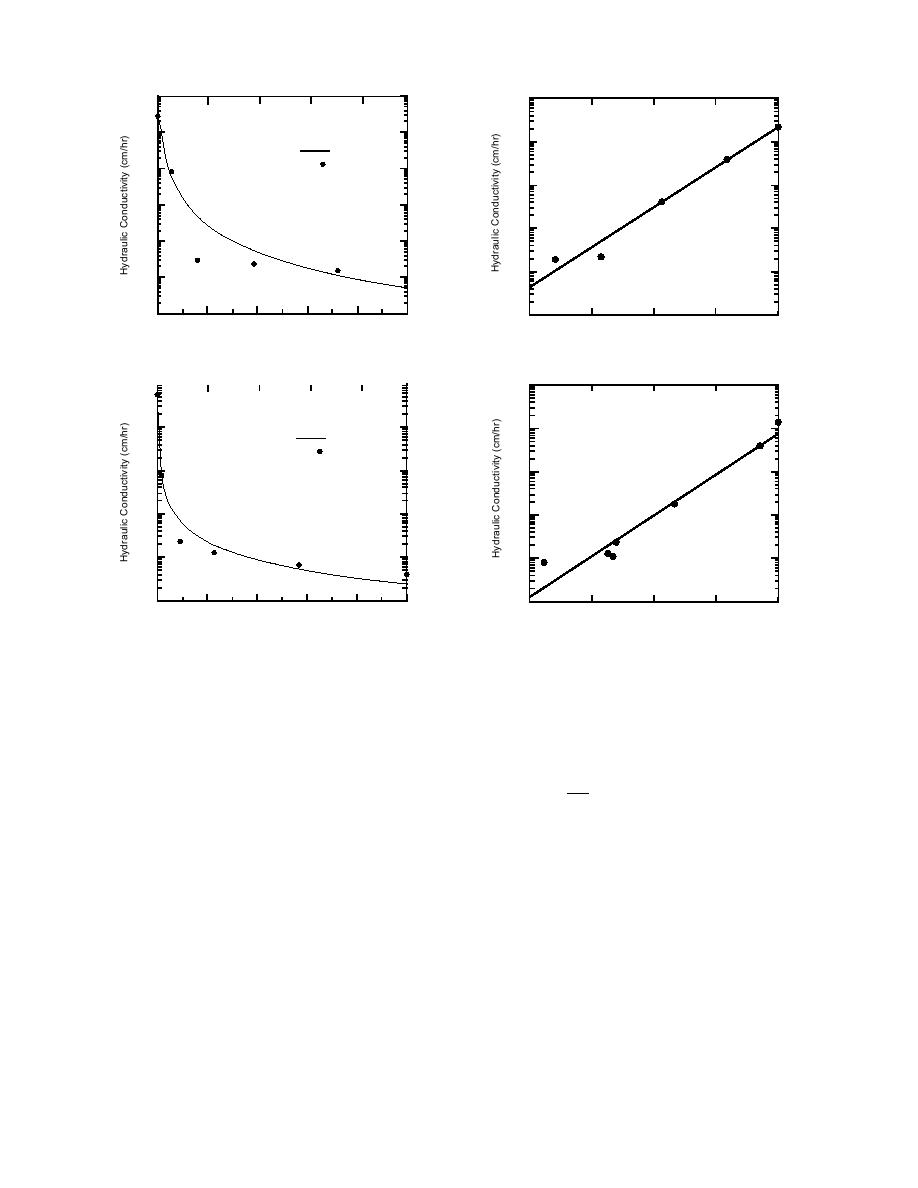

Taxiway A Subbase

γ d = 2.16 Mg/m 3

0

10

G s = 2.79

2

10

Calculated

1

Extraction

10

3

10

102

4

10

3

10

5

10

104

Sample 1171

5

6

10

10

0

100

200

300

400

500

80

85

90

95

100

Tension (cm water)

Degree of Saturation (%)

a. Subgrade sample 1171 (563)

g. Taxiway A subbase.

0

40

20

1

1

10

10

Dense-graded Stone

γ d = 1.89 Mg/m 3

0

10

2

G s = 2.80

10

Calculated

1

Extraction

10

3

10

2

10

4

10

3

10

5

10

4

10

Sample 1206

6

105

10

0

100

200

300

400

500

80

85

90

95

100

Tension (cm water)

Degree of Saturation (%)

b. Subgrade sample 1206 (565).

h. Dense-graded stone.

Figure 8. Degree of saturation vs. hydraulic

Figure 7 (cont'd). Tension vs. hydraulic con-

conductivity curves. Solid line is an exponen-

ductivity curves. Solid line represents Gard-

tial regression fitted to both the extraction

ner's equation approximation of the extrac-

and absorption data, when available.

tion data.

The best fit lines shown in Figures 7 and 8 are

β

-T

those that are generated from eq 1 and 2. Other

wu = α

; T < 0C

(3)

T0

equations may fit data from some samples better,

but the Gardner's form equation is that currently

where wu = gravimetric unfrozen moisture content

employed in the mechanistic design procedure.

(%)

T = temperature (C)

Unfrozen moisture content

T0 = 1.0C

The variation of unfrozen moisture content with

α and β = constants

temperature was determined by testing each mate-

rial with a pulsed nuclear magnetic resonance tech-

nique (Tice et al. 1982). The cooling curve data

Table 8 presents the constants determined for

are presented in Appendix E and in Figure 9. The

each sample. The class 6 special stockpile material

figure also includes a curve of calculated values

was split into two fractions above and below the no.

used to represent the data in the mechanistic pro-

30 sieve. The calculated curve represents the equa-

cedure, produced with an equation in the form:

tion developed for the minus no. 30 sieve fraction.

16

Previous Page

Previous Page