30

0

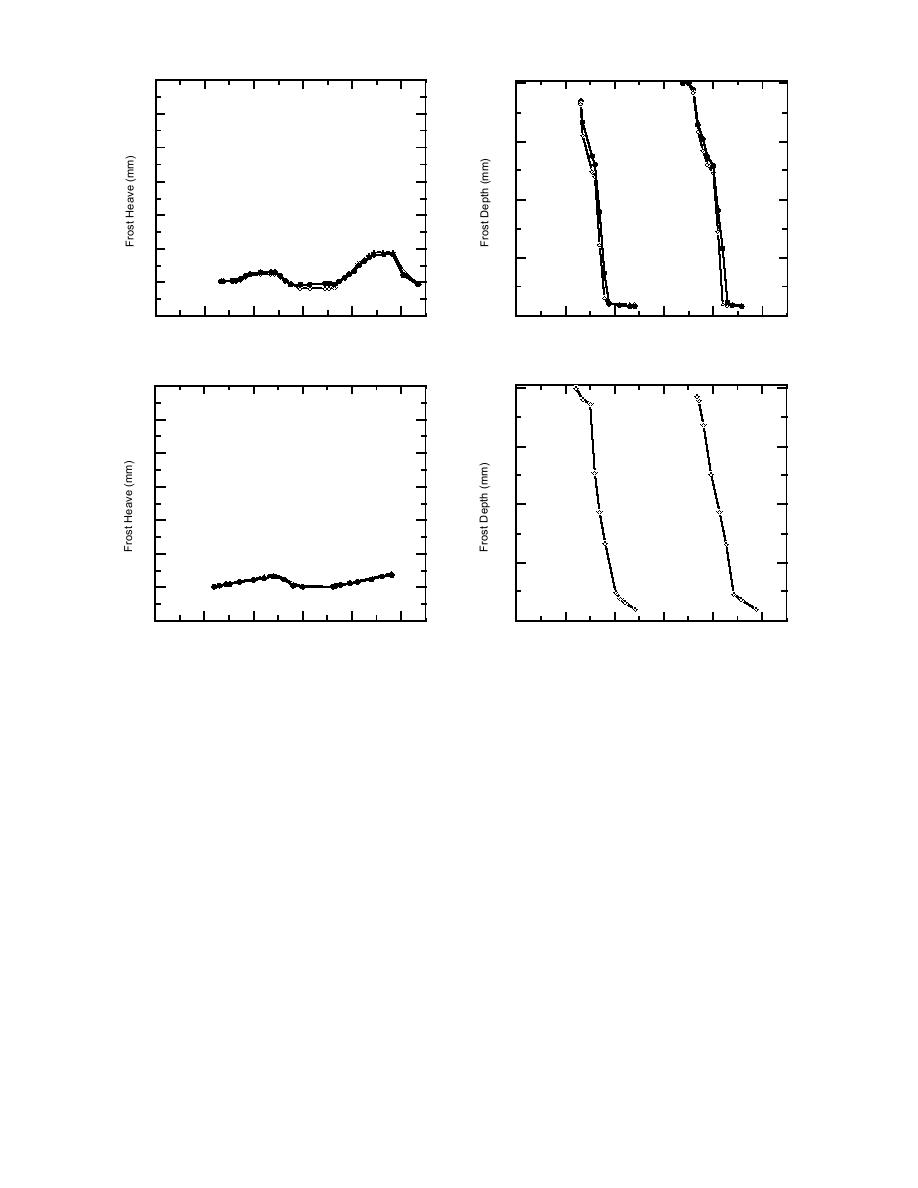

Subgrade 1232

δd = 1.78 Mg/m3

25

w = 17.8 %

-40

20

15

-80

10

5

-120

0

-5

-160

0

20

40

60

80

100

0

20

40

60

80

100

Time (hr)

Time (hr)

d. Subgrade sample 1232 (566).

30

0

Class 6 blended

δd = 2.11 Mg/m3

25

w = 5.1 %

-40

20

15

-80

10

5

-120

Sample 2

0

Data Not

Recorded

-160

-5

0

20

40

60

80

100

0

20

40

60

80

100

Time (hr)

Time (h)

e. Class 6 special blended.

Figure 4 (cont'd).

Of the two substitute materials, frost suscepti-

test begins with a saturated sample that is dried

bility data are available only for dense-graded stone,

incrementally to determine point values of mois-

as reported by Chamberlain (1986). Figure 5 shows

ture content and pore pressure head, during what

the heave data, which are summarized in Table 5.

is termed the drying or extraction phase of the

The data indicate that the frost susceptibility

test. Incremental amounts of moisture are then

classifications of the subgrades range from me-

reintroduced to the sample in the wetting or ab-

dium to very high. The well-graded class 6 special

sorption phase. At each moisture condition, an

base has negligible frost susceptibility, and the

unstaturated hydraulic conductivity test is also

dense-graded stone (class 5 substitute) ranks as

conducted. Materials tested included subgrade

having medium frost susceptibility.

samples 1171, 1206, and 1232; class 3 special and

class 6 special blended materials; and class 3 spe-

Hydraulic properties

cial stockpile material. Data are also available for

Moisture retention and unstaturated hydraulic

both substitute materials for class 4 special and

conductivity tests were conducted in a pressure

class 5 special. Appendix D contains data from

cell permeameter using the procedures described

the moisture retention and unstaturated hydraulic

in Ingersoll (1981). A typical moisture retention

conductivity tests.

11

Previous Page

Previous Page