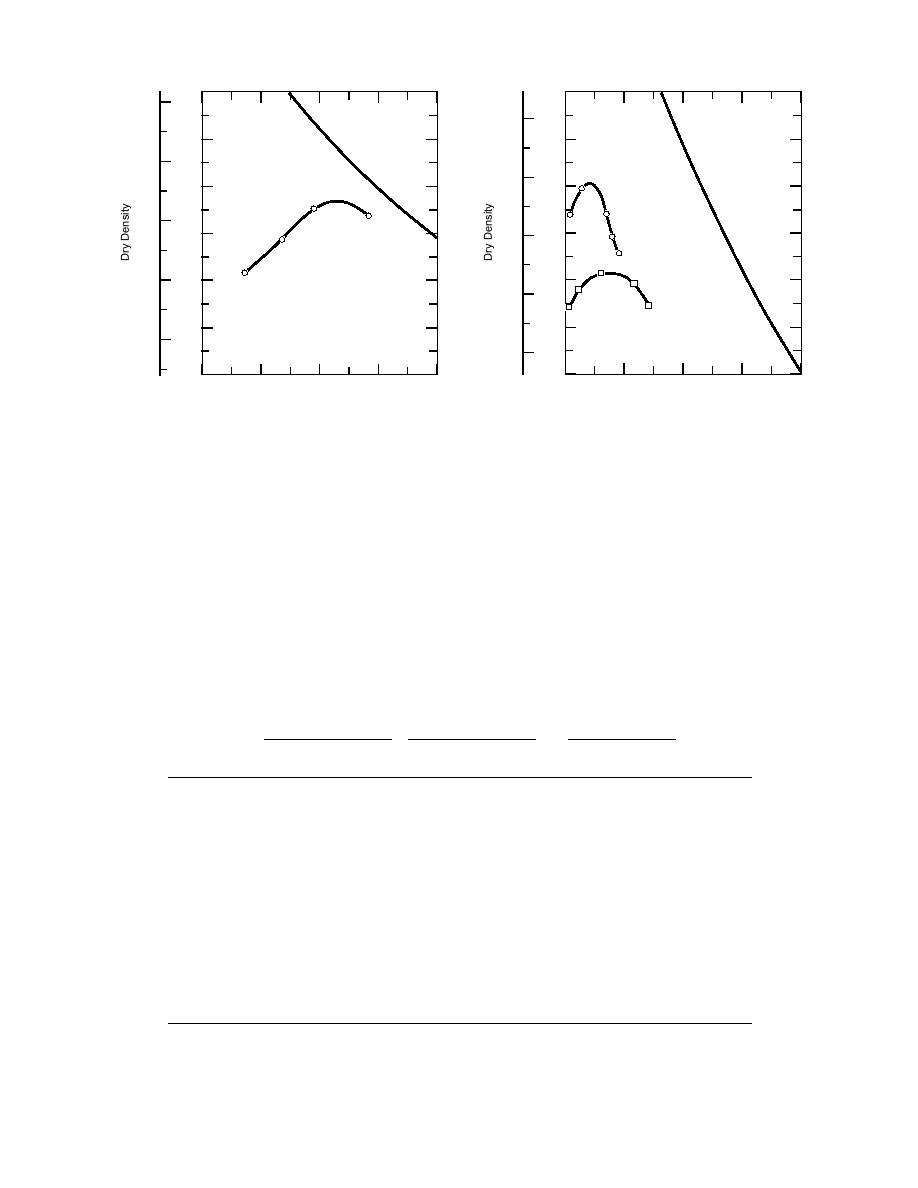

(Mg/m 3) (lb/ft 3)

(Mg/m 3) (lb/ft 3)

140

140

2.2

Class 6 Stockpile

Class 3 Blended

2.2

130

135

2.0

S = 100%

2.1

130

CE - 55

120

CE - 12

1.8

S = 100%

125

110

2.0

120

1.6

100

CE - 12

1.9

90

115

1.4

1.8

110

80

0

5

10

15

20

0

5

10

15

20

Water Content (%)

Water Content (%)

h. Class 6 special stockpile.

g. Class 6 special blended.

Figure 3 (cont'd).

variation of the frost heave and frost depth data

using the criteria shown in Table 4. Results from

recorded during the tests, which are also reported

these tests are used as a relative index rather than

in Appendix C. It should be noted that when

a quantitative predictor of behavior.

samples of subgrade 1206 and 1232 were frozen a

A partial frost susceptibility test was conducted

third time to prepare them for the frozen resilient

on the class 3 special stockpile material, but equip-

modulus testing, both soils heaved at a rate that

ment problems were discovered while running the

would have been considered highly frost suscep-

test, and the results are not presented.

tible. The data suggest that the frost susceptibility

Table 5 summarizes the frost susceptibility

of the subgrade may increase with increasing

test results for the subgrade samples and the class

freeze-thaw cycles.

6 special blended material. Figure 4 plots time

Table 5. Frost susceptibility test results.

1st freeze cycle

2nd freeze cycle

CBR test

Hv rate

Rating*

Hv rate

Rating*

CBR

Rating*

Overall

Material

(mm/day)

(mm/day)

(%)

rating

Subgrade

1171 (563)

1

V. low

7.5

Medium

2

High

Medium

1193 (564)

9.3

High

22.5

V. high

<1

V. high

V. high

1206 (565)

9.3

High

16

High

<1

V. high

V. high

1232 (566)

1

V. low

7.5

Medium

2

High

Medium

Class 5 (dense stone)

Sample 1

3.0

Low

3.0

Low

7

Medium

Low

Sample 2

NF

--

4.3

Medium

11

Low

Medium

Sample 3

5.5

Medium

5.4

Medium

11

Low

Medium

Sample 4

5.3

Medium

5.3

Medium

12

Low

Medium

Class 6

blended

<1

Negl.

<1

Negl.

29

Negl.

Negl.

* Frost susceptibility rating

9

Previous Page

Previous Page