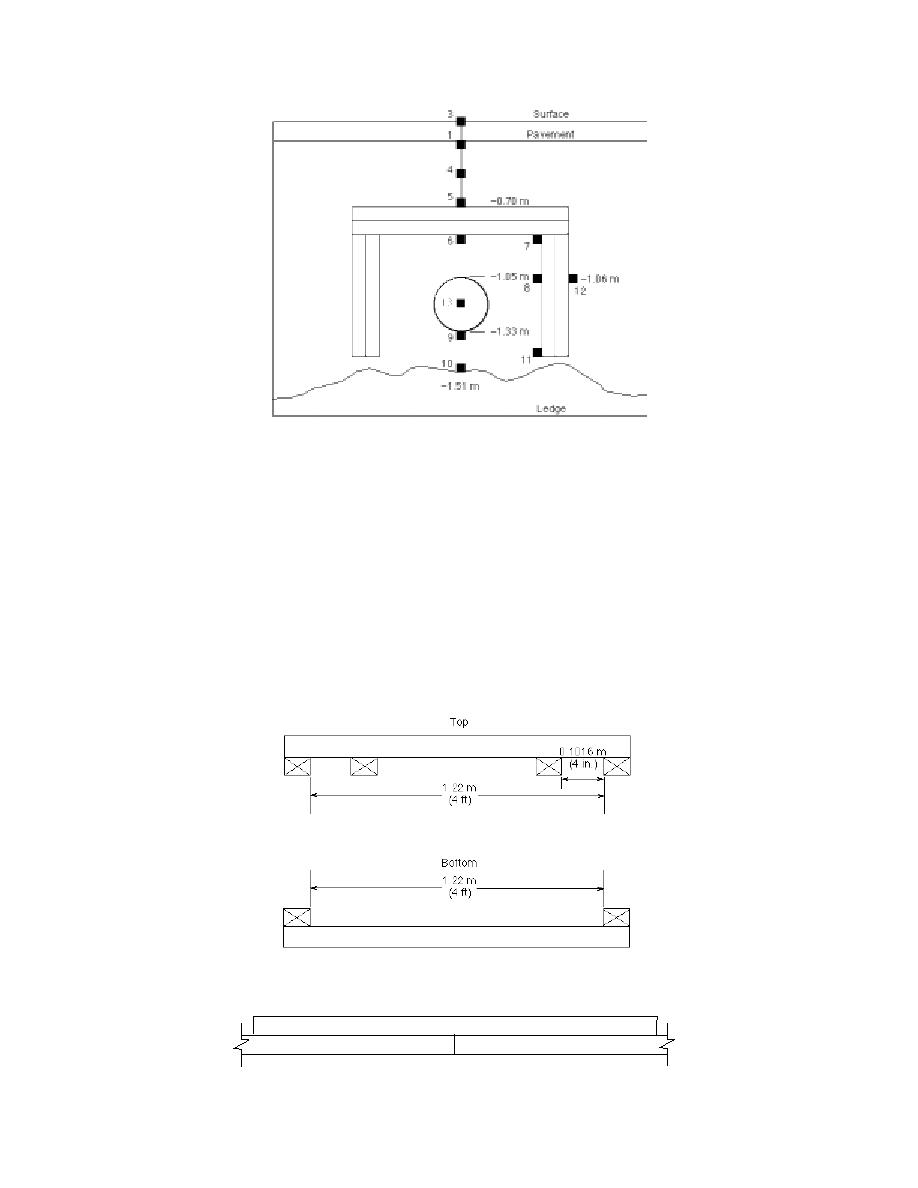

Figure 8. As-built configuration on Wentworth Street show-

ing thermocouple locations as small squares. Bottom of pipe at

test site was about 1.33 m (4.4 ft) deep with top insulation

board about 0.7 m (2.3 ft) below surface.

boards to hold them in place during construction

up to the level of the top of the shield side walls

(Fig. 9), and all the shield joints were staggered

and had been compacted, the excess was screed

(Fig. 10) to prevent thermal short circuits. The

off and the top horizontal boards were laid (Fig.

sand backfill was added evenly to the inside and

11). Care was taken to position the boards so there

outside of the shield to prevent the soil pressure

were no gaps between them and the vertical side

from collapsing the walls, and it was compacted

boards. These top boards were also staggered to

with a vibratory compactor. After the sand was

prevent thermal short circuits.

Figure 9. Jigs made from 2 4 lumber to hold insulation

during installation.

Figure 10. Staggered insulation board joints.

8

Previous Page

Previous Page